Introduction to product technology

Shape moving picture type 3 d scanner has a number of patented technology, using the latest international code calibration technology (technique of synchronous leading domestic, international advanced), the technology is the core of the technology of three-dimensional photogrammetry mastery and application of reducing physical distortion the original 3 d scanning data precision is improved. In this paper, the technology of multi-frequency phase shift with heterodyne method is used to improve the quality of scanning point cloud. In sync with gom in Germany, the scanning system of blue light device is true, and the scanning data point of 3d scanner can reach 0.01 mm, which is suitable for fine workpiece scanning. Adopt the new international core design concept, apply carbon fiber material, improve the stability of the product work.

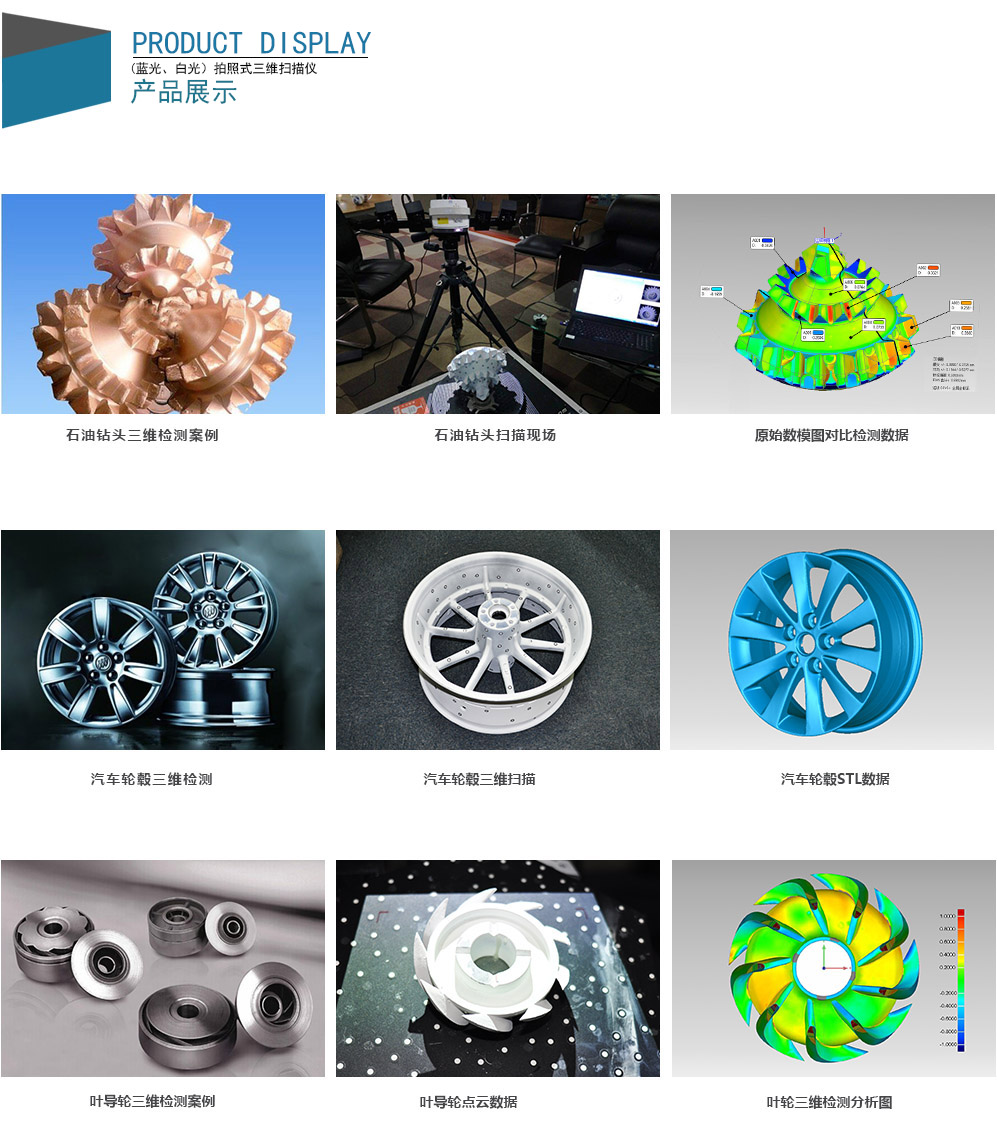

3d scanner hl-3ds + technical features:

1.13 step coding calibration technique: eliminating lens distortion error and improving scanning accuracy

2. Heterodyne method multifrequency phase shift grating: uniform stripe projection, point cloud data with high accuracy and noiseless data

3. Portable design: the hardware system is small, small in size, no noise, easy to remove and easy to pack, convenient to bring to the measuring site

4. The scanning speed is extremely fast: within 3-5 seconds, millions of data points can be obtained, and the efficiency is extremely high (also can be customized according to customer requirements).

5. Compatible camera system makes scanning speed and accuracy higher, plus or minus 0.006 mm/m

6. Patent design: eliminate the common 3 d scanner scans the problem on the stitching not from multiple perspectives Cumulative scanning precision, single machine can finish about 4 m artifacts scanning, data without the steps, deformation, striped pattern scanning, easy adjustment, for a variety of artifacts

| Product number | HL-3DS (binocular) | HL-3DS+ (four mesh) |

| Field of application | Precision molds, 3C products, electronic components, jewelry design, electronic connectors, etc. Reverse engineering, 3D inspection |

| scanning method | Non-contact 3D scanning (photographed 3D scanning) |

| Projection, grating technology | Microstructured light projection, extrapolation multi-frequency phase shifting technique (optional: blue/white light) |

| Calibration technique | Ring code calibration (13 steps) |

| Single scan range (mm) | Independent mode | 200×150 | 400×300 |

| ○ | 100×75 |

| Adjustment mode | 400×300 | 200×150 |

| 200×150 | 50×40 |

| 100×75 | ○ |

| Single measurement accuracy (mm) | ±0.006 |

| Single-sided scan time (S) | <5,<3 |

| Stitching method | Fully automatic intelligent stitching, manual feature stitching |

| Scannable object range (mm) | 10~4000 |

| Average sampling point distance (mm) | 0.01-0.47 |

| Industrial 3D Photogrammetry (Accuracy) | Support industrial 3D photogrammetric splicing engineering coordinate point file import (≤±0.04mm/4m) |

| industrial camera | Resolution (pixels) | 1.13 million pixels (optional 2 million, 3 million or 5 million pixels) |

| Camera angle (degrees) | 18 degrees, 27 degrees, 32.5 degrees |

| Industrial lens (mm) | 18 degrees, 27 degrees, 32.5 degrees |

| Calibration unit | Metal/glass/granite |

| Industrial console | Mobile tripod / professional work bench / heavy duty operating frame |

| Data output format | ASC,STL,PLY, IGES |

| operating system | Windows xp/windows 7/windows 10 32 bit / 64 bit Chinese / English |

| Light source, energy (W) | Standard 100 W Halogen LED, 50 W High Energy LED (White); High Energy Lamp (HPL) 250 W Halogen |

| Calibration board | Square granite material calibration plate |

| Working temperature, power supply | 0~40℃、100~240V AC |

| Test Report | Equipment accuracy test report issued by the Institute of Metrology and Quality Inspection, calibration test report |

| Camera platform | 360 degree free adjustment platform |

| Camera platform | System size (mm) | 360x150x125 | 580x150x125 |

| System weight (kg) | 2.8 | 3.3 |

Demand feedback

Customers can make service requests to the company through effective communication methods such as telephone and mail. We will respond within 2 hours and propose solutions within 24 hours.

Equipment Repair

Our company responded to customer questions in the first time after receiving the product failure notice. After the effective communication methods such as telephone and mail can not rule out the equipment failure, and the problem is determined as the cause of the equipment, our company assigns technical personnel to the site for maintenance.

China Optical Three-dimensional Tian Jin Technology Co.,Ltd

Tel: 86-022-59002803 59002807 59002817 59002805

Fax: 86-022-59002805

Fax: 86-022-59002805

Tel: 17720035950

Address: 3rd Floor, South Building, Tianda Science and Technology Park, No. 80, Fourth Avenue, Tianjin Economic and Technological Development Zone