3D inspection of steel castings

Steel casting is a workpiece made of steel casting. Its properties are similar to cast iron, but its strength is better than cast iron. Steel castings are prone to porosity defects and inaccurate angle positioning in the casting process. With the accelerated upgrading of the manufacturing industry and the continuous improvement of manufacturing technology and process level, there will be higher requirements for product quality.

Scanned steel castings

Practical problem

The customer is producing steel castings. He wants to test the problems between the produced steel castings and the original digital simulation. The scanning area of steel castings is large, and the use of a new hand-held three-dimensional scanner can reduce the premise sticking work and improve the work efficiency. Traditional surveying and mapping methods have been difficult to meet the needs of the current market. There will be large cumulative deviation, long time and high cost in the detection process.

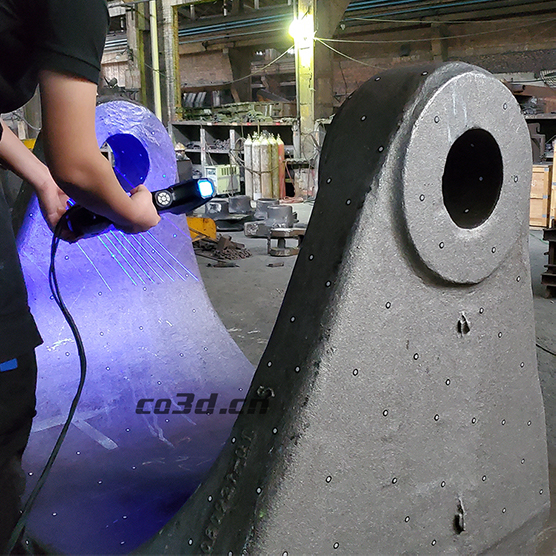

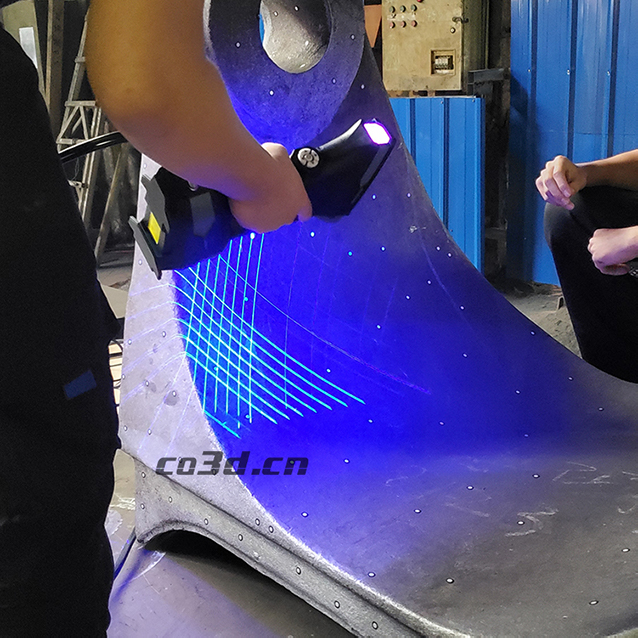

Field scan of steel castings

Field scan of steel castings

Co3d solutions

Huaguang technical engineers use the new handheld 3D scanner holon751 to comprehensively scan steel castings to obtain high-precision 3D data. The scanner has the advantages of fast scanning speed, short time and high work efficiency. Import the acquired data into the three-dimensional detection software for fitting and comparison with the original digital analog to obtain a simple and easy to understand detection report. Customers can get detailed comparative data from the report and know the existing problems, so as to solve the customer's problems.

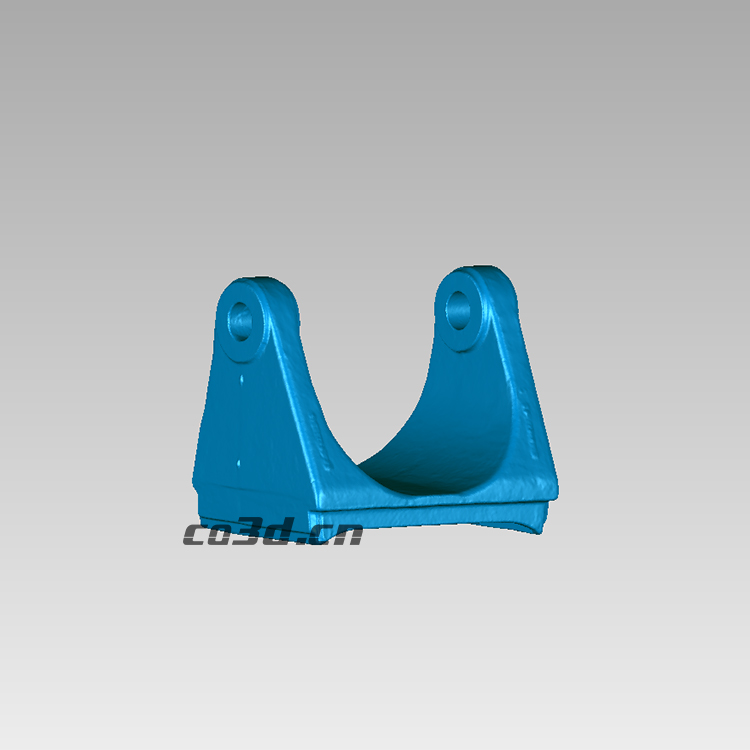

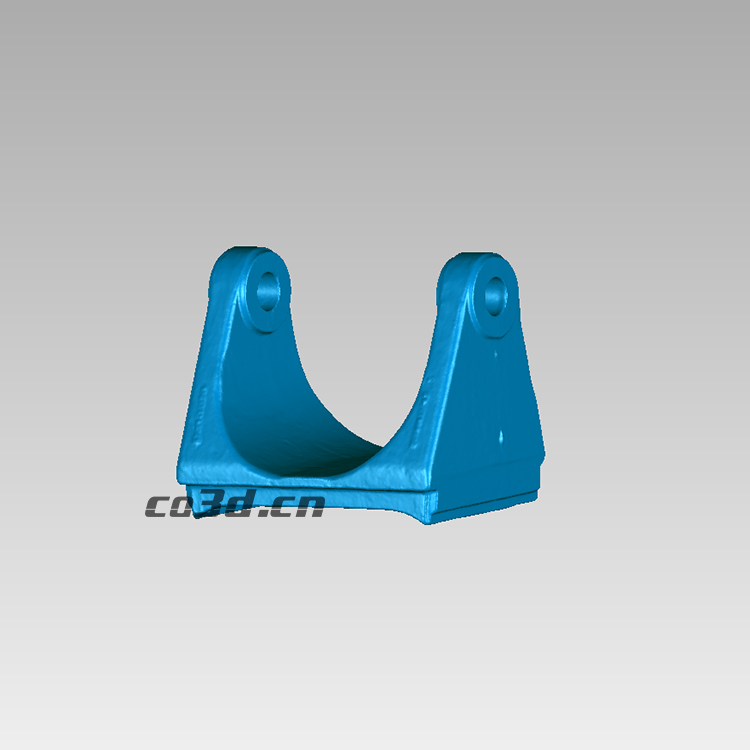

Scanning STL data diagram of steel castings

Scanning STL data diagram of steel castings

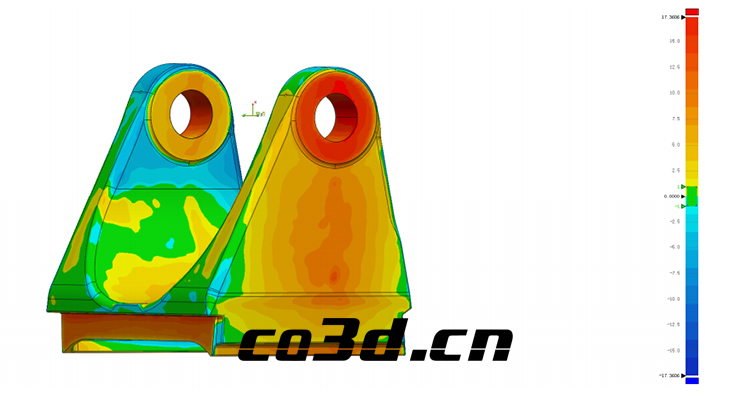

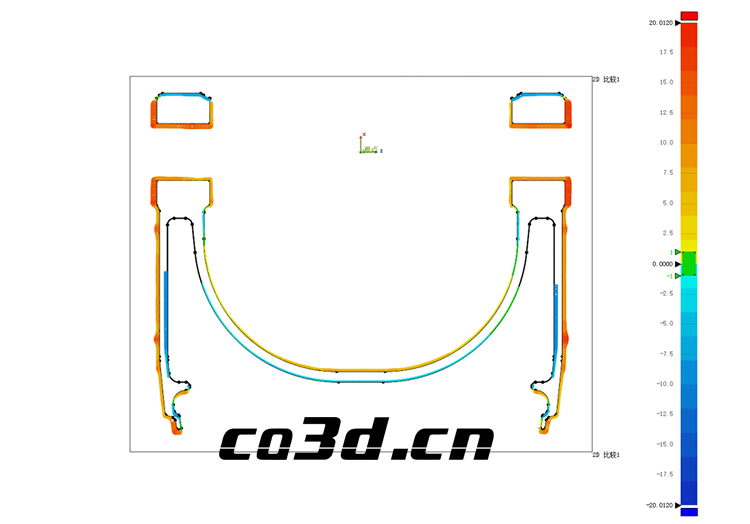

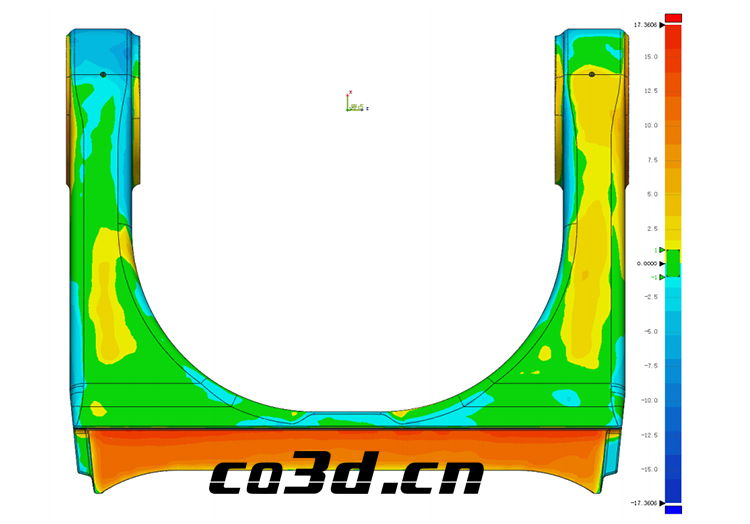

Inspection data diagram of steel castings

Inspection data diagram of steel castings

Inspection data diagram of steel castings