After a hundred years of development, the conveyor has become one of the important equipment for conveying bulk materials. With the continuous expansion of the scale of modern agriculture, industry, transportation and transportation industry, as well as the higher requirements for material transportation in the transportation process, such as the increase of the requirements for economy, reliability and efficiency in the material transportation process, in order to meet the market demand and improve the competitiveness of enterprises, customers decided to abandon the traditional measurement methods and introduce new scanning and comparison methods. We learned that Holon 3D is the first handheld 3D scanner manufacturer in China, which can quickly and accurately obtain data, comprehensively compare and analyze whether products are qualified, and improve product quality and detection efficiency.

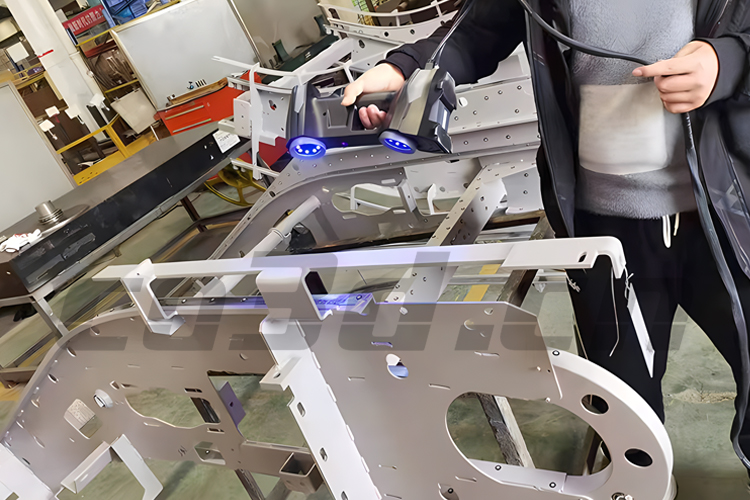

Scanning site drawing of elevator conveyor belt underframe

Practical problem

1. The customer is the manufacturer of conveyor belt conveyor. In order to make the conveyor more stable and reliable, three-dimensional data detection is carried out on the underframe of the conveyor. There are many holes on the surface of the conveyor and the structure is complex.

2. Using a fixed scanner is inconvenient and inefficient. Customers require the 3D scanner to scan high-precision and complete data with high efficiency, detect the error of actual processing, and ensure the stability and reliability in the operation process

Scanning site drawing of elevator conveyor belt underframe

Holon solutions

Equipment: Handheld 3D scanner Holon B71

Using all blue laser scanning, fearless of black surface objects; The scanning speed is 1350000 measurements / s, and the scanning can be completed in 10 minutes; The accuracy is as high as 0.02mm, with dual industrial cameras, automatic mark splicing technology and independently developed scanning software, which has high scanning accuracy and work efficiency. By comparing with the original data, the actual processing error is detected to meet the scanning requirements of customers, and the problems faced by customers are successfully solved.

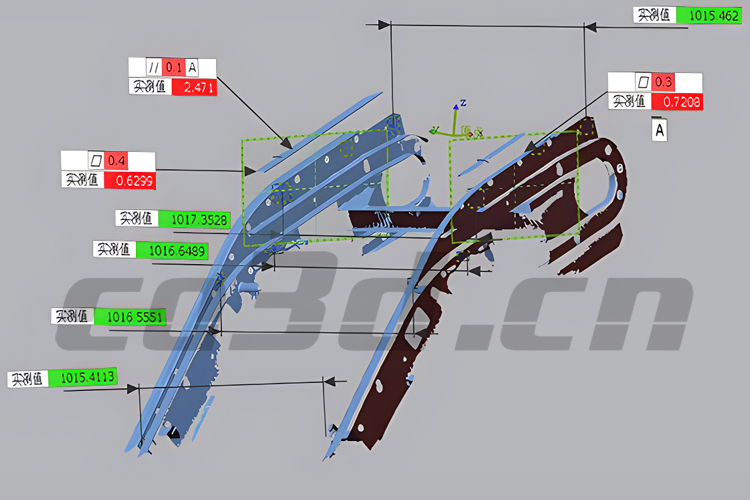

STL data diagram of elevator conveyor belt underframe scanning

Comparison and inspection diagram of elevator conveyor belt underframe