Three dimensional inspection of heavy load gearbox

The reason why the gear can operate safely for a long time depends on an invisible oil film on the outside. The external gear box acts as a sealed container. In order to make the gear work stably for a long time under the condition of high speed and heavy load, it is essential to detect the quality and size of the gear box. The overall outline of the gear box is collected according to the high-density point cloud data to ensure that the early product design fully meets the processing requirements.

Pracical problems

1. The structure of the gearbox is complex, and there is a special tubular structure on the surface. The early data collection is faced with the difficulty of incomplete data in a large range.

2. There are many holes on the surface of the gearbox. The collection of hole data determines the consistency of later installation, so the accuracy of hole data is highly required.

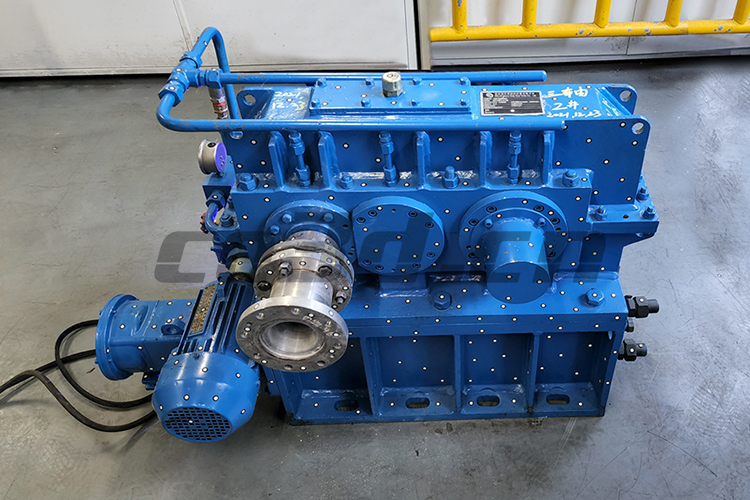

Heavy load gearbox scanning site

Solutions

In view of the characteristics and requirements of the customer's workpieces, HOLONB71, our hand-held three-dimensional scanner, is used, which has fast scanning speed, high accuracy and strong stability. The automatic stitching technology of landmarks and independently developed scanning software have ultra-high scanning accuracy and work efficiency.

Use a scanner to comprehensively scan the gearbox to obtain data, and fine mode can be used to scan the location of the detail hole, so as to obtain data with high accuracy. Compare the acquired high-precision 3D data with the standard mathematical model of the gearbox, and generate a simple and understandable comparison test report to provide data support for later gearbox processing.

Heavy load gearbox scanning site

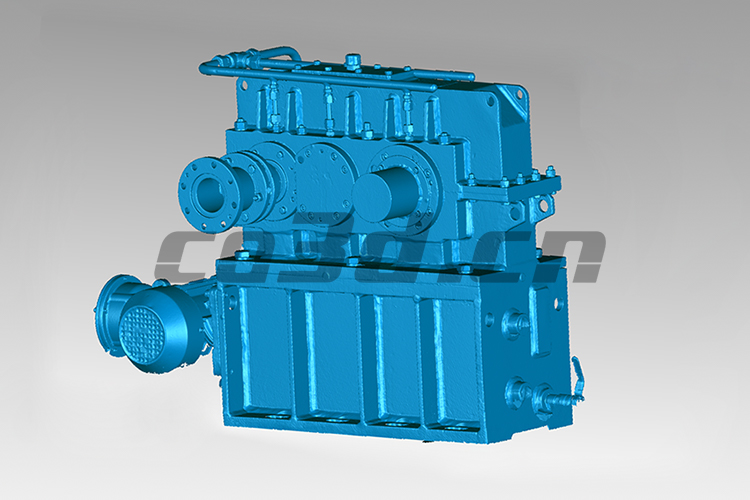

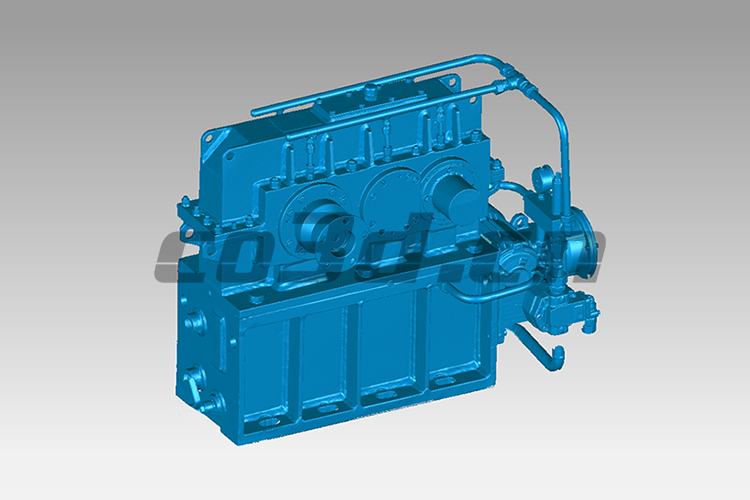

Heavy duty gearbox STL data diagram

Heavy duty gearbox STL data diagram