A rolling machine is a universal device that bends metal sheets into cylindrical, arc-shaped, or other shaped workpieces. It is based on the principle of three-point rounding and utilizes changes in the relative position and rotational motion of the workpieces to generate continuous plastic deformation of the sheet, in order to obtain a predetermined shape of the workpiece.

Product physical image

Practical problems

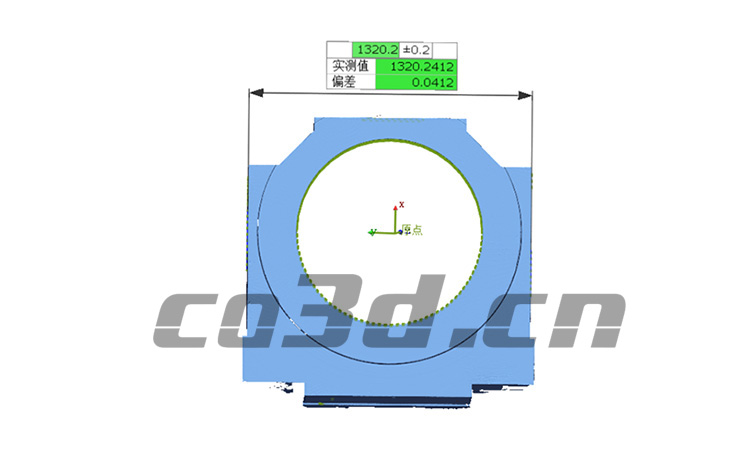

It is necessary to conduct three-dimensional testing on the casting of the rounding machine to obtain data such as its diameter, width, flatness height, and distance between the side and the hole center. The workpiece itself has a large volume and a curved surface. Customers need to quickly scan the workpiece, and the scanning data requires high accuracy. Using traditional detection methods for manual measurement is slow, with inaccurate data, and many small defect areas cannot be effectively measured, which can easily lead to secondary errors.

Scan on-site images

Co3d solution

Faced with scanning difficulties, Hualang 3D engineers use a handheld 3D scanner HOLON B71, which is flexible and convenient to operate, suitable for various complex application scenarios. It uses 30 blue laser lines, with fast scanning speed, high accuracy, and stronger stability. Quickly obtained 3D data of the machined part, measured its diameter, width, and flatness, saving costs and meeting customer scanning needs.

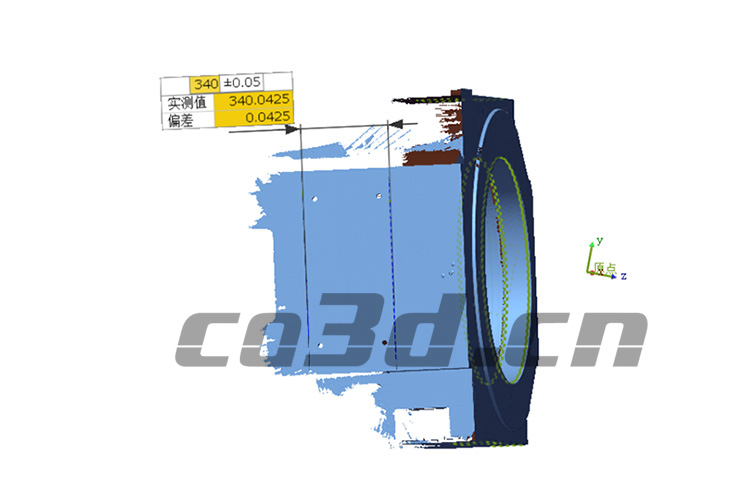

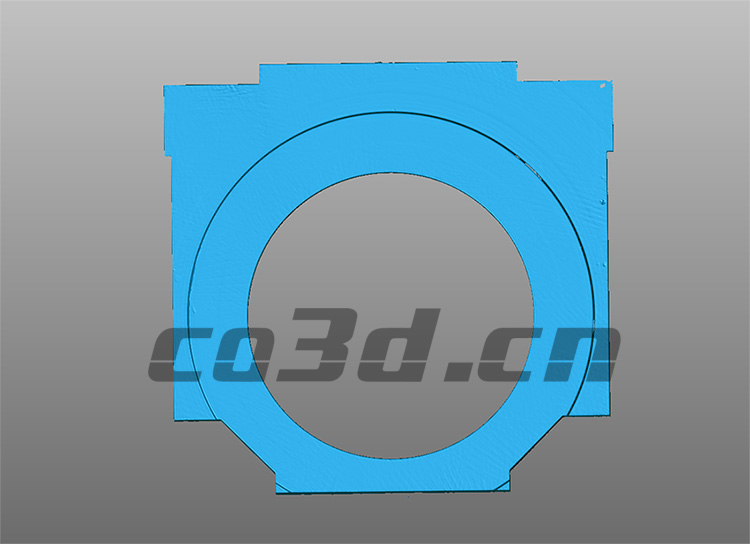

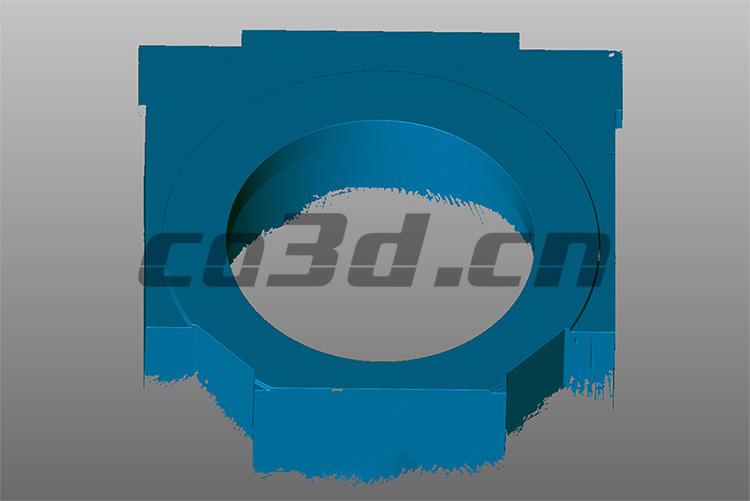

STL data graph1-1

STL data graph1-2