Three dimensional detection of wind turbine blades

Wind turbine blade design directly affects the conversion efficiency of wind energy, which directly affects the annual power generation, aerodynamic performance of the airfoil with a better aerodynamic performance of the airfoil and aerodynamic analysis. The airfoil is the aerodynamic shape of the blade, which directly affects the utilization of wind energy. Airfoil has the advantage of high lift coefficient and lift drag ratio under design conditions, and has good performance in the non design conditions.

Wind blade 3D scanning spot

Practical problems

1 for the detection of wind turbine products, the use of traditional measurement tools can not be effective measurement of wind blades.

2 wind blade surface curvature is larger, ordinary 3D scanner device can not make accurate 3D data measurement.

Long about 9m, wide 1m multi wind turbine blade photography measurement site

CO3D solutions

A domestic enterprise to produce Canada, length 9m, width 1m of the wind blade products testing and certification, testing analysis of wind turbine blade 3D scanning data with the original two-dimensional map, two design and product improvement work for wind turbine blades.

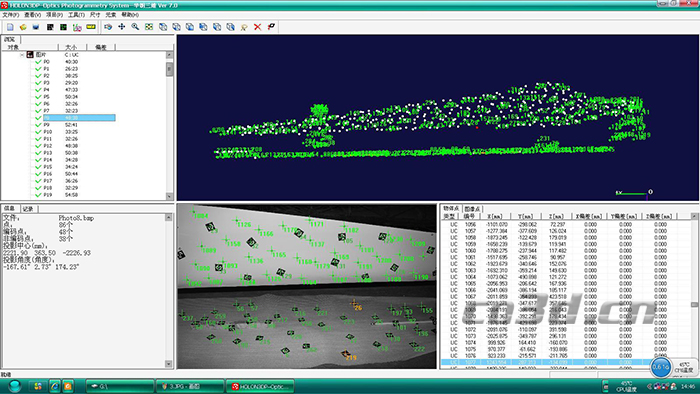

The wind turbine blade surface area, number of cases, three Solutions Engineer Huaguang scanning equipment used in 3D scanner: alpha 7000; 3D Photogrammetry System HL-3DP

Wind power blade 3D scanning spot

A, Huaguang engineers use 3D photogrammetry 3D HL-3DP system from different angles on the measured blade film image into photogrammetry software and then taken, the software will automatically according to the principle of triangulation to calculate the overall framework of the measured blade.

Long about 9m, wide 1m multi wind turbine blade photography measurement site

B, three dimensional scanner alpha 7000 to carry out a comprehensive three-dimensional measurement of wind blades, to obtain the three-dimensional measurement data of wind turbine blades.

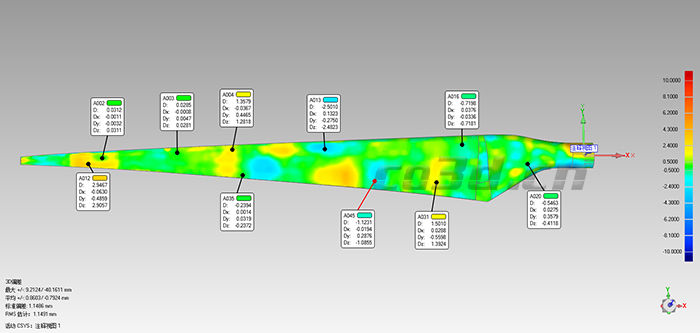

C, using the reverse design software to analyze the deviation of the number and size of the high quality surface model, and then design and adjust it according to the analysis results.

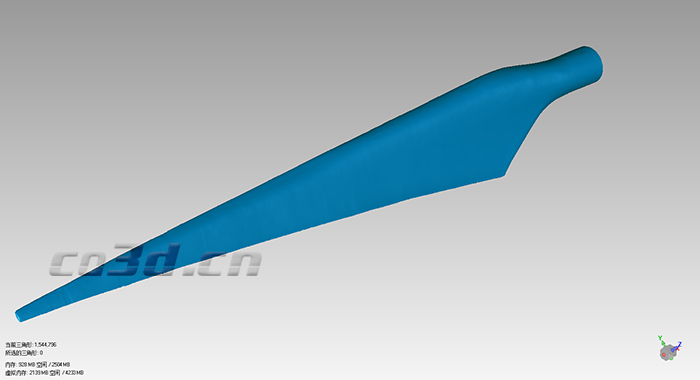

Wind blade STL data chart

Three dimensional measurement of wind blade on the left

Wind blade data chart