Super large steam turbine 3D scanning

In order to measure the super large steam turbine casing, a large domestic famous thermal power plant company invited our technicians to carry out three-dimensional scanning on the turbine casing of the enterprise to obtain high-precision three-dimensional data, thus providing effective data support for the production design of the steam turbine insulation cabin.

Practical problems

1. The steam turbine casing is welded by large castings, which is about 5m long and about 2m high. The scanning environment is complicated and the scanning difficulty is increased. It takes a long time to use traditional measuring tools and it is impossible to carry out complete scanning and data splicing.

2. During the scanning process of the turbine casing, the object to be measured is large and cumbersome, the surface contour is different, the shape is complicated, and the cumulative error is too large. How to eliminate the influence caused by the error is the biggest problem.

CO3D solutions

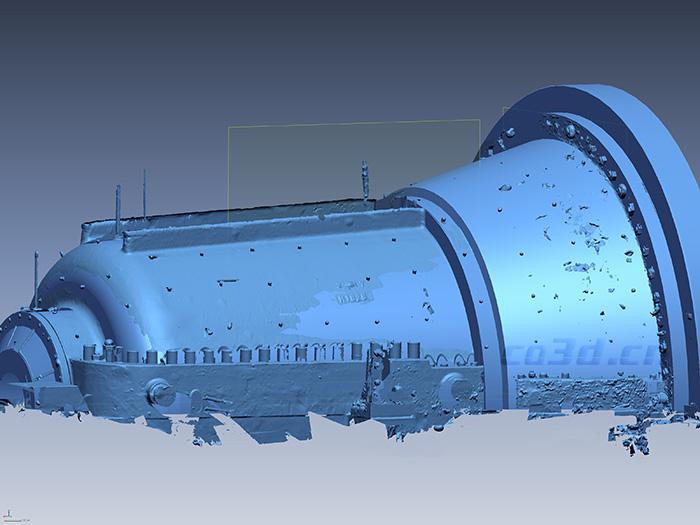

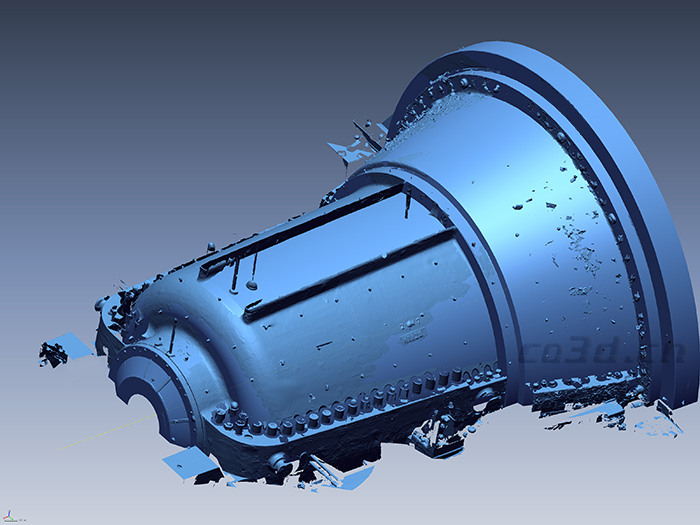

The steam turbine is divided into two parts for scanning and the scanning area of the casing is large. In order to eliminate the problems of scanning cumulative error and complete splicing, the three-dimensional technical engineer proposes a solution: using the ultra-large-format 3D scanner α7000 and the 3D photogrammetric system 3DP to quickly acquire the steam turbine. The high-precision 3D data of the shell combined with the reverse design software converts the steam turbine shell point cloud data into triangular mesh surface data. It provides powerful data for the production design of the turbine insulation cabin.

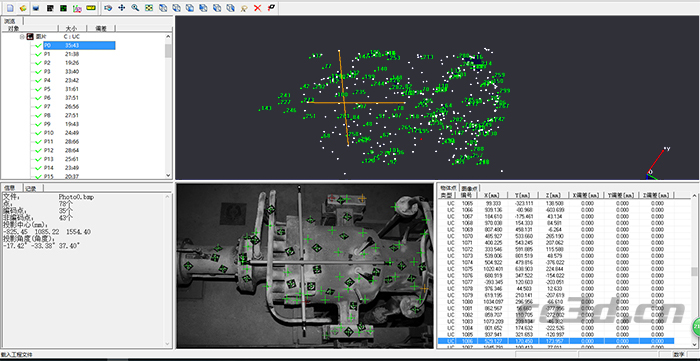

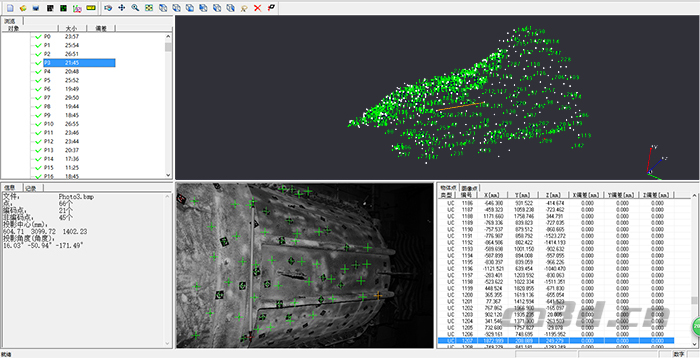

The 3DP is a portable optical coordinate that measures the three-dimensional coordinates of all landmarks (or codes) at a time. Can be used alone or in combination with a 3D scanner. The high-resolution digital camera is used to take photos from different angles during measurement, and the resulting series of photos can be solved by software to obtain the precise spatial coordinates of these reference points.

Α7000 is a 3D scanner for large objects. It has large scanning width, fast scanning speed, high precision and strong equipment stability. It can correct the point cloud information of large-area surface with 3D photogrammetry. , greatly improve the overall point cloud stitching accuracy of the 3D scanner, and improve work efficiency.

Super large steam turbine on-site physical map

Large steam turbine site physical map

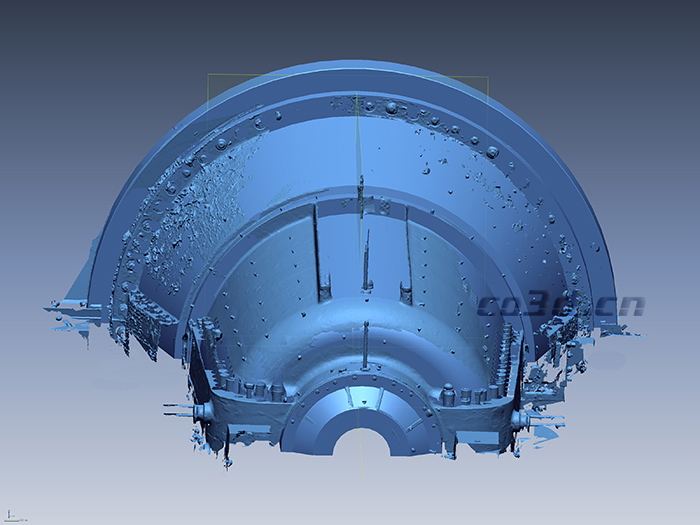

Super large steam turbine three-dimensional data map

Large steam turbine measurement site

3D data chart of large steam turbine

Large steam turbine STL data chart

Large steam turbine STL data chart

Large steam turbine STL data chart