Automobile bumper mold inspection

The 3D data of a famous auto parts production company to get bumper mold bumper to establish 3D model files (CAD drawings), to provide data support for the structural design, automobile bumper mold modification design and subsequent quality inspection.

Practical problems

1 automobile bumper mold is larger, the production of the product is easy to produce deformation, so the quality control of the rod is very important, and the 3D data of the die is very high precision.

2 only use traditional detection methods (such as fixture, jig, three coordinate etc.) is very cumbersome and time-consuming, and is not easy to structure of automobile bumper mold for accurate and rapid measurement, detection.

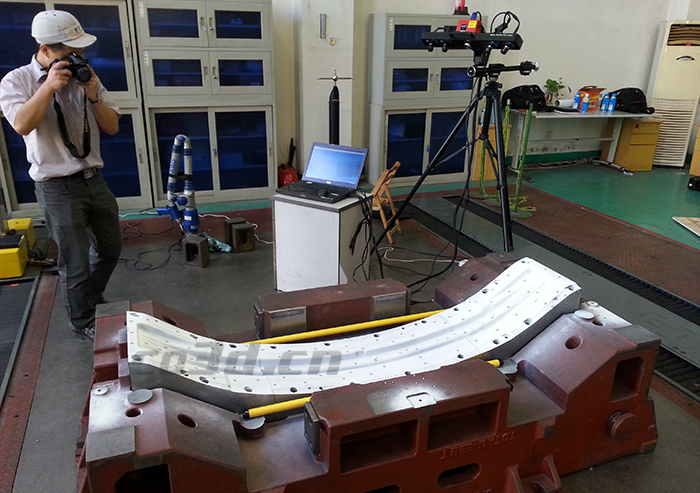

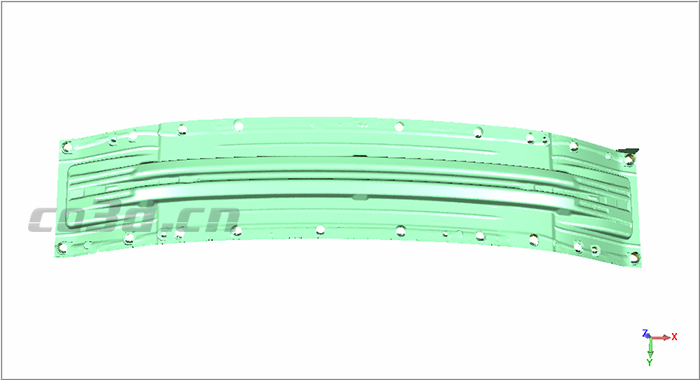

Auto insurance Rod Die scanning spot

CO3D solutions

Aiming at the problems faced by customers, Huaguang 3D technology engineers use 3D scanner (HL-3DS and fast to the automobile bumper mold were scanned to obtain high density point cloud data) + reverse combined with professional design software (such as Imageware, Geomagic, Studio) + 3D detection software (assist the company compared to the products and product model diagram)

1, the preparatory work

Spray developer: improve the sample surface color contrast scan data to obtain better.

Paste labeling: positioning stitching in the scanning software makes access to the data.

Automobile bumper mould

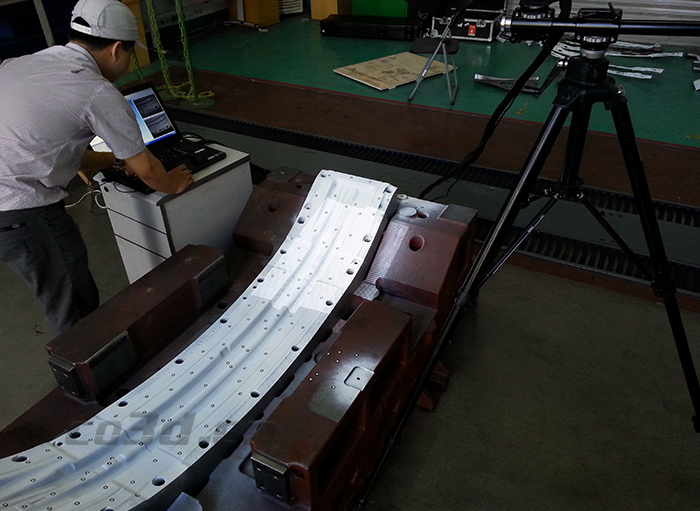

2, three-dimensional scanning

Three dimensional scanner (HL-3DS) scanning speed, access to the car bumper mold 3D data only 10 minutes, the data accuracy of up to 0.02mm. Three dimensional scanner (HL-3DS) using the interpolation method of multi frequency phase shift grating technology, coding point calibration technology and automatic splicing technology. To import the 3D data of the die of automobile insurance rod into the three-dimensional reverse soft (Geomagic).

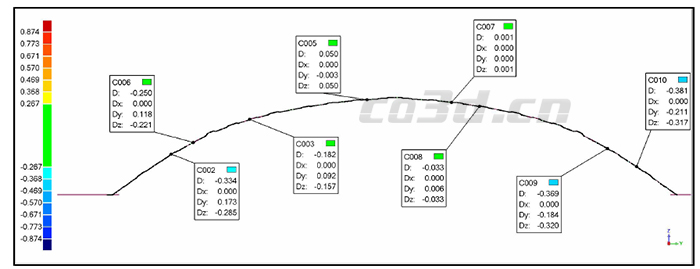

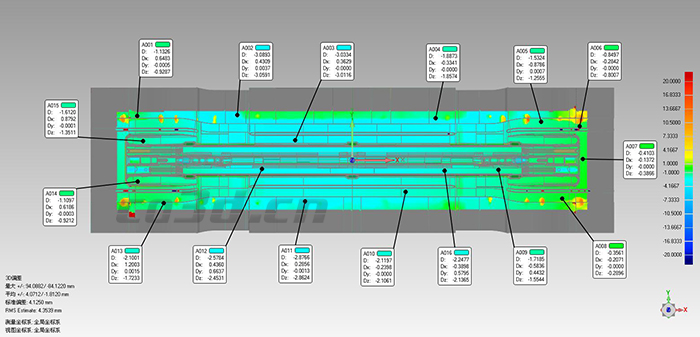

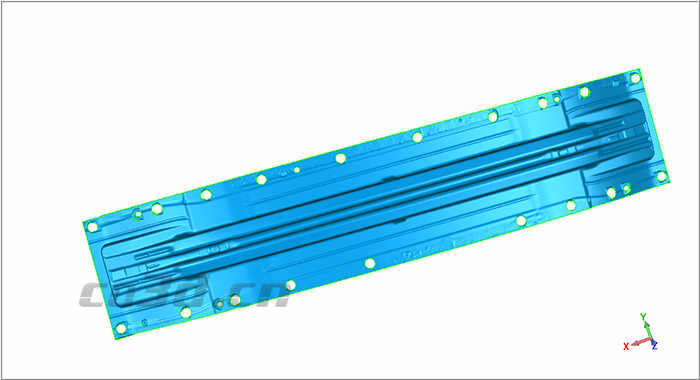

3, three-dimensional detection

Will Qualify into the bumper mold 3D data obtained by Geomagic detection software, can quickly detect the automobile bumper mold (CAD) the difference between manufacturing and product model, Geomagic Qualify with an intuitive graphical comparison results to show the difference.

Drawing of cross section of automobile insurance

Automobile bumper contrast detection

Car bumper point cloud data

Car bumper STL data