Racing suspension system 3D scan

Huaguang engineers use type 3D Scanner Camera 'HL-3DS+' for the Guangdong International Speedway racing team of a scanning suspension, customers need high precision 3D data obtained by scanning the car suspension system debugging, the car can show excellent performance in the game.

Practical problems

Suspension system is one of the most difficult parts of the whole vehicle, the structure of the system is complex, the parts are fine, and the dead angle is much.

The customer requires the car's four suspension systems to be in the same coordinates.

CO3D solutions

Ready to work: Huaguang engineers are spraying agent

The car suspension system is defined by the body and tire between the spring and shock absorber and other parts of the whole support system, it has to support the body, improve the ride feeling function. Different suspension settings will give the driver a different driving experience. Seemingly simple suspension system, in fact, a combination of a variety of forces, determine the stability of the car, comfort and safety, is one of the important parts of the whole car.

Guangdong international car field a team hopes to analyze the car's suspension system through three-dimensional data, with accurate 3D data, the car will be more scientific debugging. In the automotive industry has a wealth of experience of the engineers to scan Huaguang scan the scene, according to the characteristics of the car, the rapid development of scanning program, complete scanning, meet customer demand.

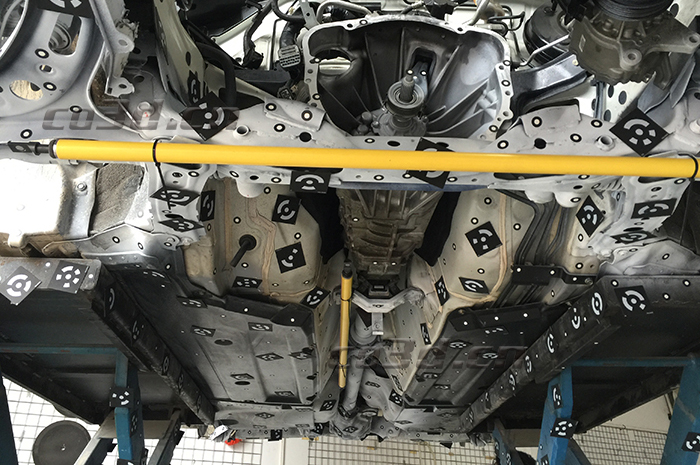

Good marking point, coding point and car chassis with good target

Customer requirements: 1, need to obtain the data of vehicle suspension system especially shock absorber and swing arm, and the precise position of each sheet metal screw.

Four, 2 suspension systems need to be in the same coordinates.

Use of equipment: 3D scanner 'HL-3DS+', three-dimensional Photogrammetry System 'HL-3DP'.

Total time: 4.5 hours.

Scan results: a success, the accuracy of 0.06mm.

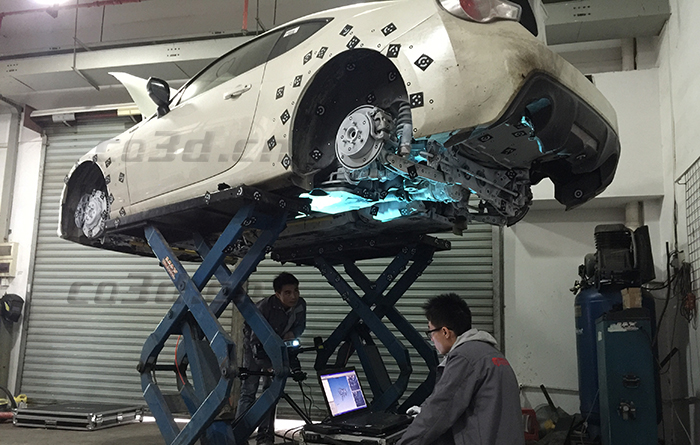

Huaguang engineers are using 3D scanning car suspension system

Scanning step:

1, the use of three-dimensional photogrammetry system:

A lot of common three-dimensional scanner manufacturers of technology is still stuck at the level of the object can be scanned. Faced with a scan of the four suspension system and ensure that the same coordinates of this type of problem, the general will scan the data for the transition to connect the target area, such as the scanning drive shaft will be linked to the front and rear suspension system. While Huaguang engineers used 3D Photogrammetry System HL-3DP, first of all a mark point position information encoding fast recorded after scanning, each piece of data scanner, 3D photogrammetry system will automatically put the corresponding coordinates, it not only needs to scan the transition objects, and reduce the scanning the number, reduce the error brought by splicing. The figure for the pole yellow thermal deformation alloy target rod, each target rod through the testing and certification authority, it will play a role in the scale of the photogrammetry process, provide more protection for the high precision 3D data acquisition.

Engineers in China are using the 3D scanner to scan the racing car suspension system.

2, three-dimensional scanning

HL-3DS+ is an industrial camera 3D scanner, single precision 0.02mm, with photogrammetry can reach 0.05mm/4m, which uses carbon fiber protection ring frame, 17 digital encoding calibration system, calibration of the 13 step direction sign automatic stitching technology, ensure high precision 3D data racing suspension, guarantee the performance of the car. Protect the life safety. In the process of scanning, Huaguang flexible mobile senior engineer, tripod, control PTZ change 3D scanner to avoid dead angle scanning, once completed more than and 60 pieces of data scanning. Frequent transfers the fuselage, scanning and stitching more format, which is one of the methods to test whether a 3D scanner is stable, however, consumers in the purchase of a 3D scanner, it is easy to overlook the stability problem of equipment. Then HL-3DS+ comes with the scanning software began to deal with three-dimensional data, automatic splicing, automatically delete duplicate data. Less than 10 minutes to generate a point cloud data, customers can according to their needs to STL/IGS/PLY/ASC/CAD and other formats.

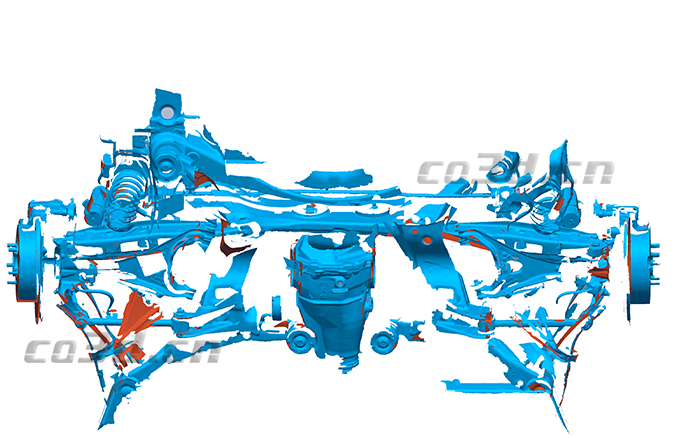

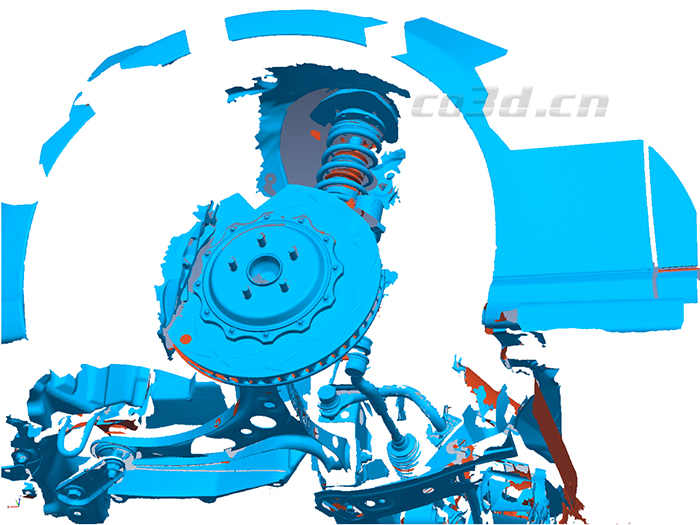

Car left front suspension 3D data

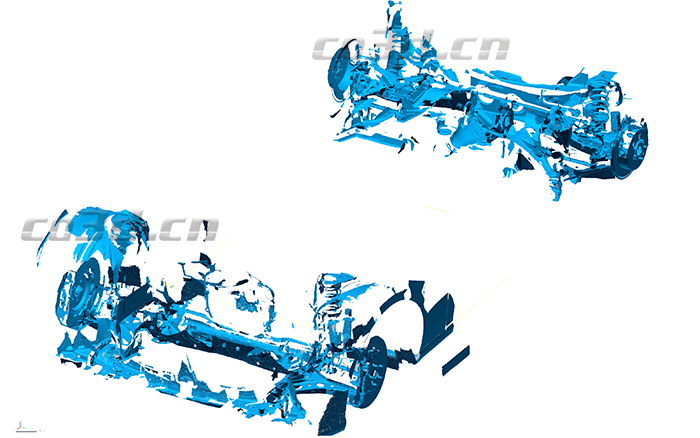

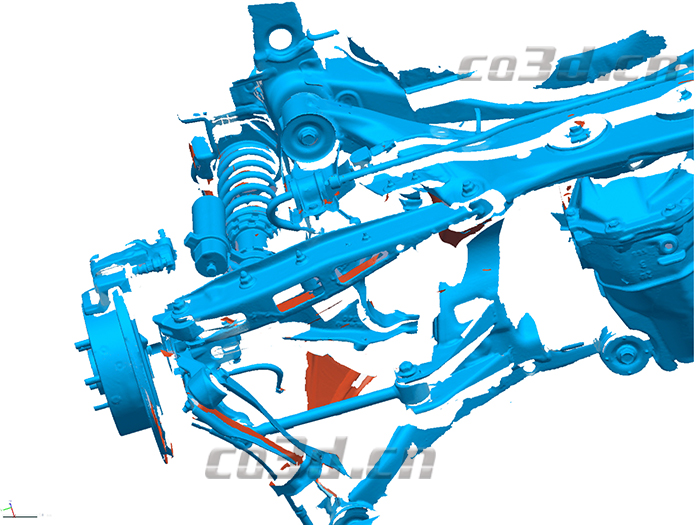

Integral 3D data for racing car suspension system (STL format)

Car rear suspension 3D data look up

Local 3D data of rear suspension system of racing car