Car hand brake 3D scanning case

Automobile handbrakes occupy a considerable proportion in auto parts, and its quality is one of the important factors that directly affect the performance and appearance of automobiles. In the face of increasingly fierce market competition, a well-known auto parts manufacturing industry I hope to use 3D scanners to enhance the technical advantages, thus improving product quality and shortening the production cycle.

Practical problems

1. The shape of the handbrake of the automobile is complicated, and the shape of the groove inside the bottom surface is different, and the contour of the curved surface is more. The use of other testing equipment may result in incomplete 3D data acquisition and cannot meet customer needs.

2, the use of traditional measurement methods (such as inspection tools, fixtures, three coordinates, etc.) is very cumbersome and time consuming. Moreover, it is not easy to accurately and quickly measure and detect the structure of the automobile hand brake component.

CO3D solutions

Due to the error in the production process of the car handbrake, due to the traditional measurement method, the acquired data is limited and the 3D data of the car handbrake cannot be accurately obtained. The 3D technical engineer is used to quickly scan with the camera type HL-3DX. Obtaining the three-dimensional data of the car handbrake, the speed is fast, the operation is convenient and the time is short, the data precision is extremely high, the customer's scanning demand is met, and the problem faced by the customer is successfully solved.

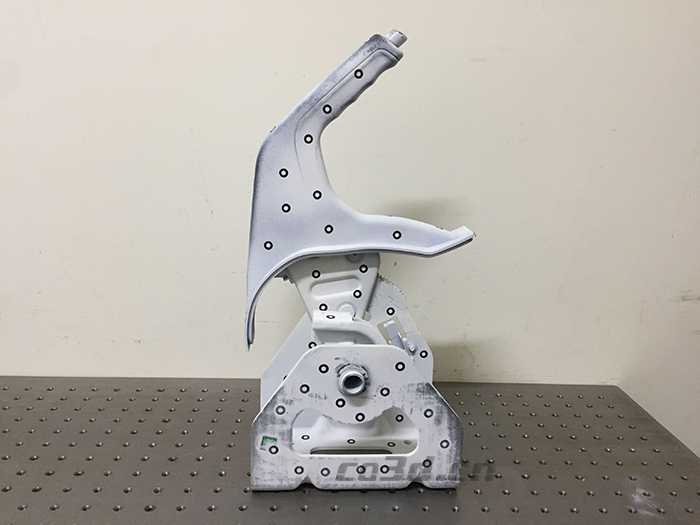

Car hand brake scene physical map

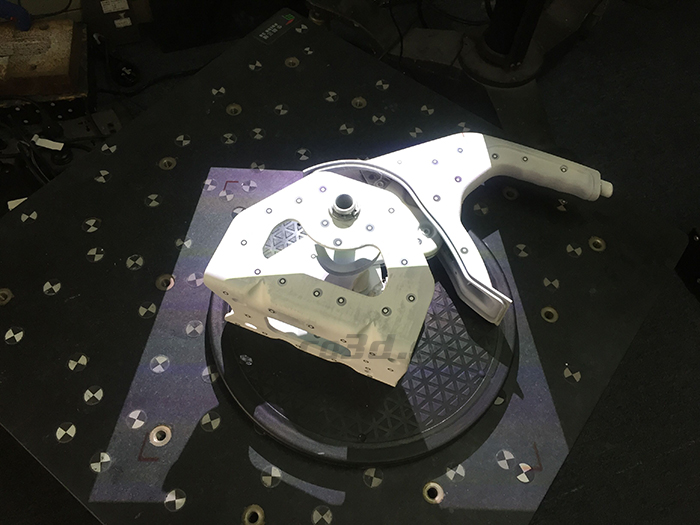

Car hand brake scene scan

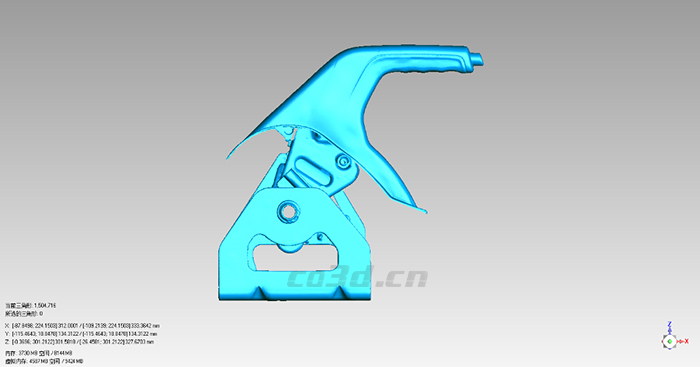

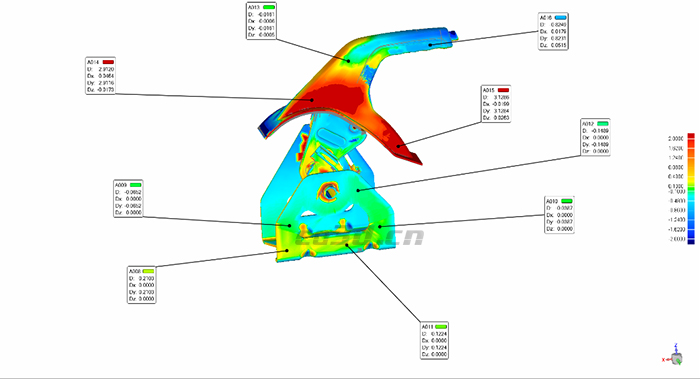

Car handbrake STL data chart

Car handbrake STL data chart

Car handbrake STL data chart

Car handbrake STL data chart

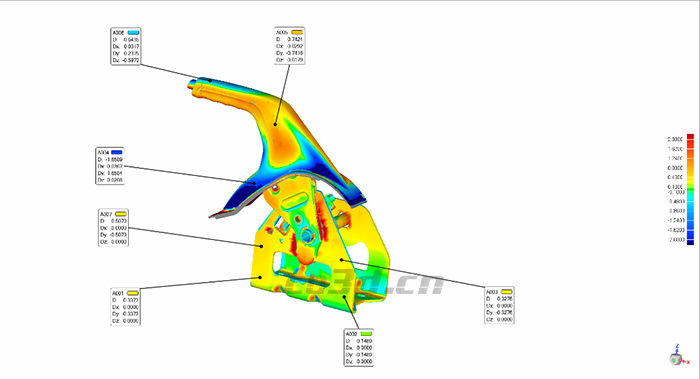

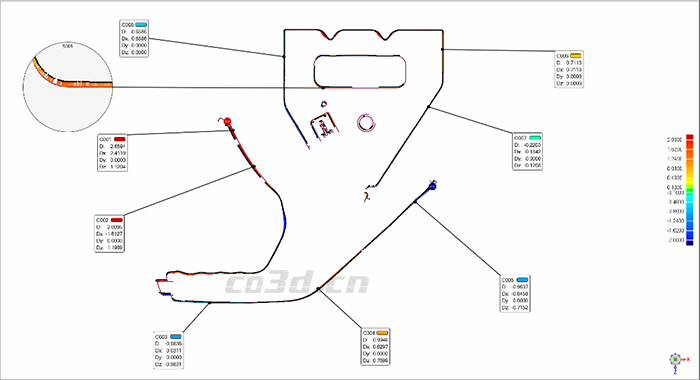

Car hand brake 3D inspection sectional view