Three-dimensional inspection of cast steel film of high iron sleeper rail

One well-known domestic China railway group need for high-speed pillow rail cast steel membrane 3 d detection, high-speed pillow rail is a very important part of railway construction, not only the relationship between the normal use of the railway also relationship with our life safety, so high-speed pillow can track the quality of the standard is particularly important.

Practical problems

1. It is necessary to measure the matching of the cast steel film and the hole position of the high iron sleeper rail casting steel film.

2. High casting iron pillow rail steel membrane corner is more, increasing the difficulty scanning, customers need to high casting iron pillow rail steel membrane fast scan, scan data for precision is very high, to be used with the original d / 3 d detection analysis.

CO3D solutions

High iron casting pillow rail steel membrane product large and bulky and contour more irregular shape and hole installation characteristics such as shape dynamic 3 d technical engineer propose solutions: using photo type 3 d scanner 3 ds fast scanning to obtain the 3 d data of high-speed pillow rail, the scanning process not only speed, high precision, easy operation and short time-consuming, satisfy the customer needs to scan and successfully resolve customer problems.

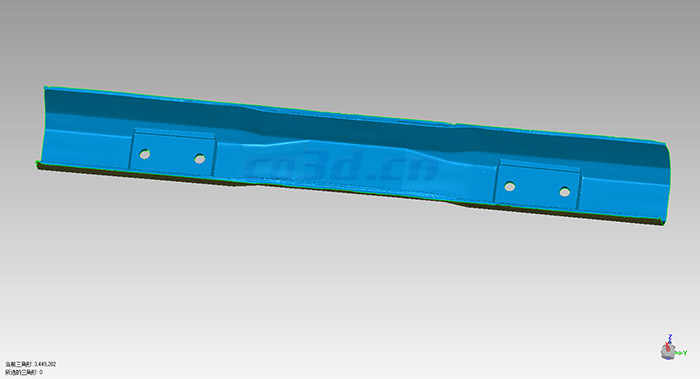

Effect of casting steel film on high iron sleeper rail

Effect of casting steel film on high iron sleeper rail

Effect of casting steel film on high iron sleeper rail

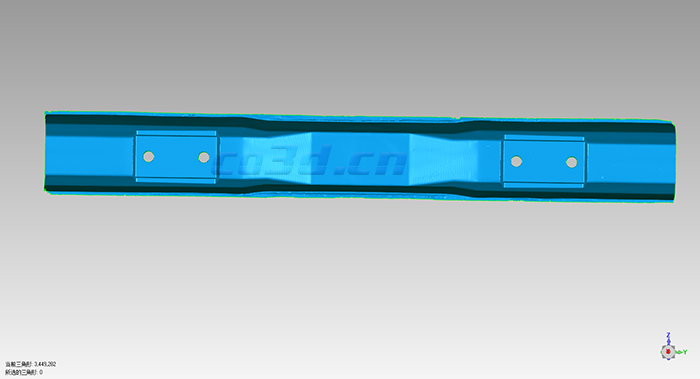

STL data graph of cast steel film of high iron sleeper rail

STL data graph of cast steel film of high iron sleeper rail

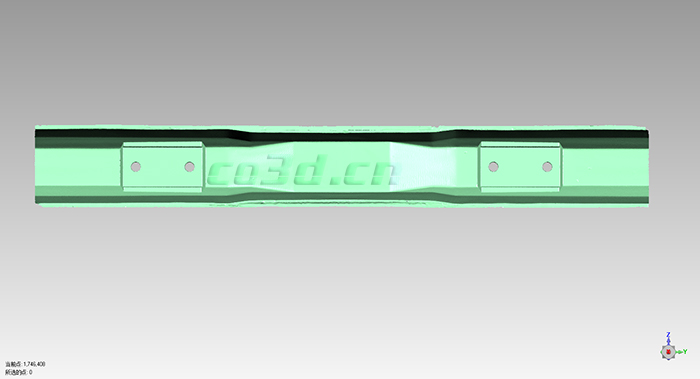

Data graph of cast steel film point cloud of high iron sleeper rail