Three - dimensional scanning is used to modify the trailer

With the improvement of life quality, the application of rv is becoming more and more popular, the form of a dynamic three-dimensional, invited by a saloon car modification company for iveco car draw 3 d scanning data, making better modification plan. After understanding the actual situation, the three-dimensional technology engineer USES 3D scanner 3DS + to quickly obtain 3D data of the rv and improve the efficiency of the refit.

Practical problems

Density of traditional measuring method of data collection is not enough (data) and for the curved surface and curve on the car can't accurate measurement, the later can't reverse mapping, big workload, low efficiency and precision is not high, can not meet the requirements of customers.

CO3D solutions

In order to shorten the development cycle, reduce the cost of car modification, form dynamic 3 d according to the problems facing the customers, put forward the solution: use 3 d scanner (3 ds +) for auto car 3 d data. The 3d scanner has the characteristics of large scanning, simple operation, extremely fast scanning speed, high precision and stability. During the scanning process, the software spliced the 3d data automatically through the marking point, and in less than 45 minutes, it obtained the entire 3d data of the entire iveco locomotive. Customers can import 3D data into software such as UG and PROE, which can greatly improve the retrofit efficiency of the rv. After the new product is completed, the customer can also import the 3D data of the product into 3D MAX and render it for product display.

The rv scene scan

The rv scene scan

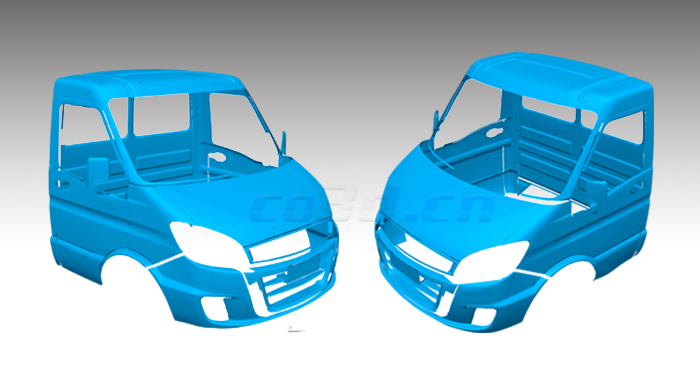

The rv dot cloud data graph

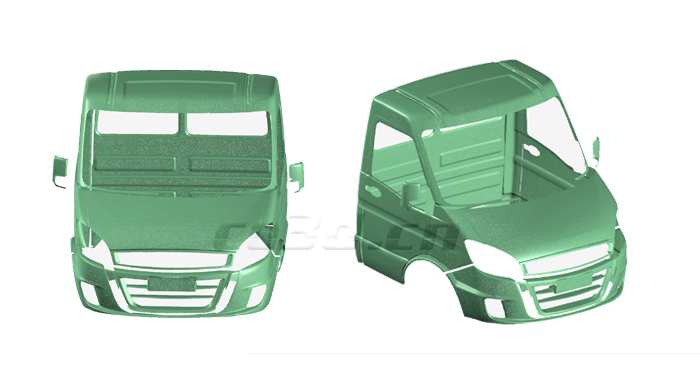

Rv STL data graph

A modified iveco trailer