BMW compressor 3D scanning case

Domestic famous BMW automobile manufacturers need to carry out quality inspection on BMW air compressors. According to the problems faced by customers, we use Huaguang Photographic 3D Scanner 3DS+ and use Geomagic Qualify to compare the 3D model of BMW Air Compressor with the entity. Analyze to obtain an accurate reconstruction model. Thereby improving the accuracy of product design, greatly shortening product development design and processing cycle and reducing costs.

Practical problems

1. BMW air compressor is very strict on the technical indicators of the project. The accuracy of the three-dimensional data of BMW air compressor is very high, and the overall error needs to be controlled within 0.05mm.

2, the traditional measurement method data acquisition density is not enough (insufficient data volume) and for the BMW air compressor surface and curvature can not be measured, and the scan object dead angle is more, not easy to scan, can not be normal detection, later can not be quality inspection and Secondary design.

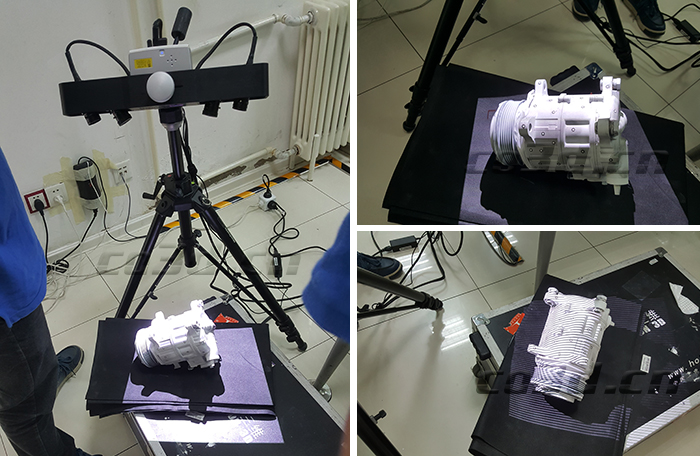

BMW compressor physical map

Co3d solutions

The quality of the construction of auto parts directly affects the overall efficiency of the manufacturing of the car, so the quality control of the car BMW air compressor is particularly important. Huaguang 3D engineers proposed the solution: 3D camera 3D scanner (fast acquisition of high-precision 3D data of BMW air compressor) + reverse design software Geomagic Studio (converted BMW air compressor point cloud data into triangular mesh surface) Data) + detection software Geomagic Qualify (quickly detecting the difference between the BMW Air Compressor (CAD) model and the manufactured parts of the product), assisting the company in research and breakthroughs in high-end technology.

1. Preparations in the early stage

Spraying the developer: Improve the background color contrast of the sample surface for better scan data.

Paste mark points: The acquired data is positioned and stitched in the scanning software.

2, 3D scanning

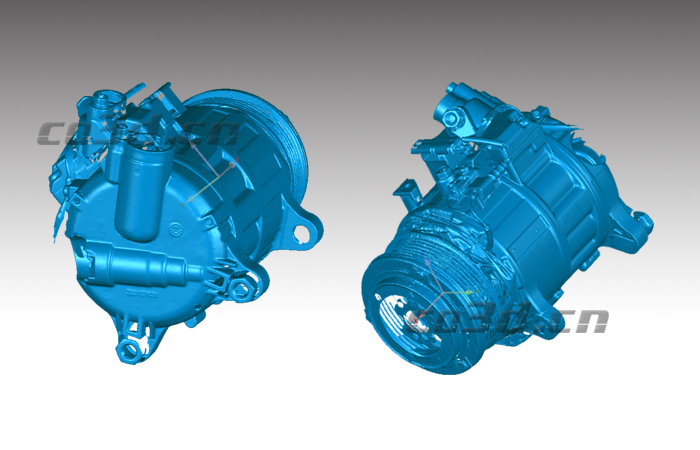

The camera-type 3D scanner (3DS+) comes with a 3D photogrammetry system with a high-precision target. Obtain high-precision 3D data of BMW Air Compressor to meet customer requirements for accuracy. The 3D data of BMW Air Compressor is imported into 3D reverse software (Geomagic) for processing, and the BMW Air Compressor point cloud data is converted into triangular mesh surface data.

BMW compressor on-site scanning

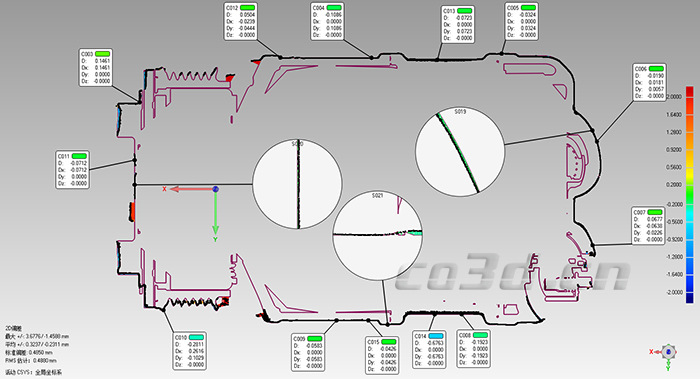

3, three-dimensional detection

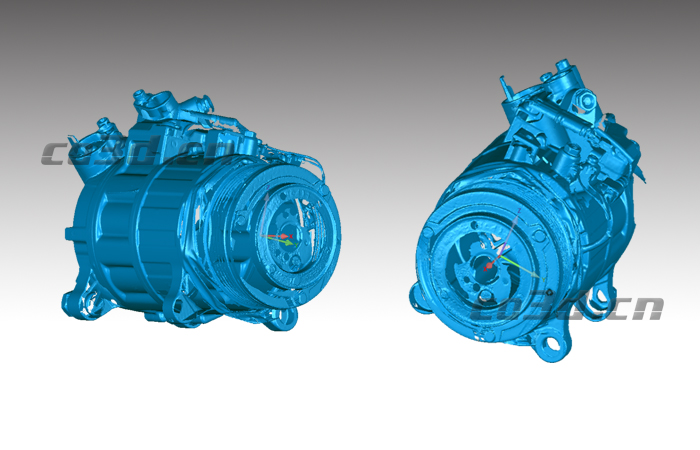

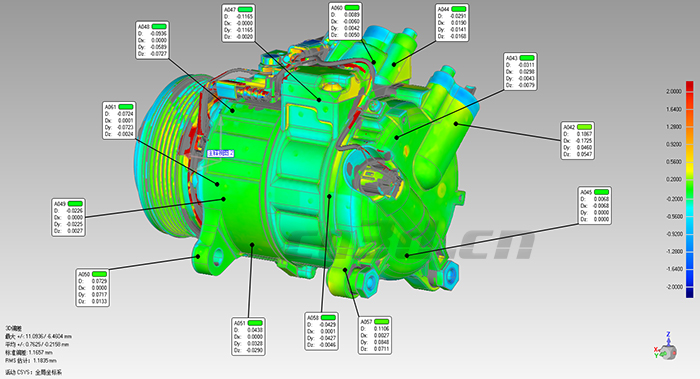

The acquired BMW Air Compressor 3D data import detection software Geomagic Qualify can quickly detect the difference between the BMW Air Compressor (CAD) model and the manufactured parts of the product. Geomagic Qualify can display the results in an intuitive and easy-to-understand graphic comparison. The difference between the two can be a detailed analysis of the characteristics of the BMW air compressor, such as hole position, contour, curvature, etc., while also capturing and reflecting the shape and position deviation of the profile. The traditional detection software can only make a simple deviation comparison between CAD data and scanned data. Through a combination of advanced software and hardware, the company successfully tested the quality of BMW air compressors, laying a solid foundation for domestic research and breakthroughs in high-end technology in this field.

BMW compressor STL data chart

BMW compressor STL data chart

BMW Compressor Cleansing Data

BMW compressor comparison data