Three-dimensional inspection of automobile engine block

An engine manufacturer in Chengdu needs to carry out three-dimensional inspection of the engine block of the automobile. The company uses the 3D scanner independently developed by Huaguang and combines the 3D inspection engineering software to obtain accurate 3D data of the engine block. The obtained engine cylinder overall data is compared with the original CAD model for targeted data, and the actual data of the engine block is actually scanned to analyze whether the finished product is qualified.

Practical problems

1. Since the engine block of the car involves connection with multiple parts of the engine, the accuracy required by the customer is very high.

2. The engine block of the automobile has the characteristics of complex shape, large surface change, and many hole positions. The traditional measurement method is very time consuming and the data is not accurate enough.

Co3d solutions

In view of the complex shape of the engine block, the large curvature change, and the large number of holes, Huaguang 3D technical engineer proposed to use the 3D scanner HL-3DS+ to quickly obtain high-precision 3D data of the engine block of the car. The 3D inspection design software converts the engine point cloud data into triangular mesh surface data + Pro/E, UG and other mainstream design software for post processing.

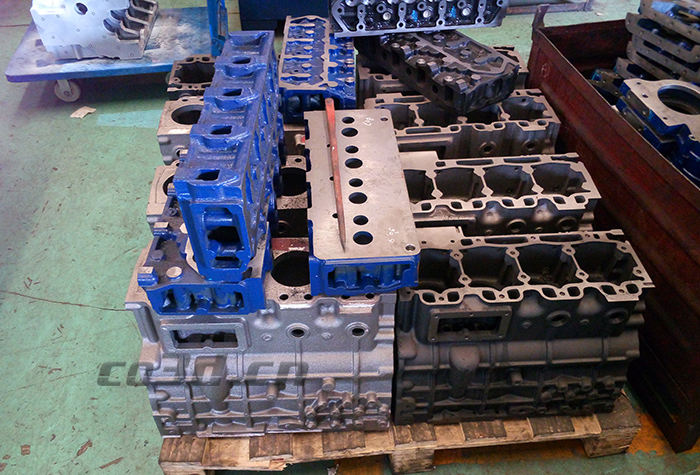

Car engine block scene

Car engine block scene

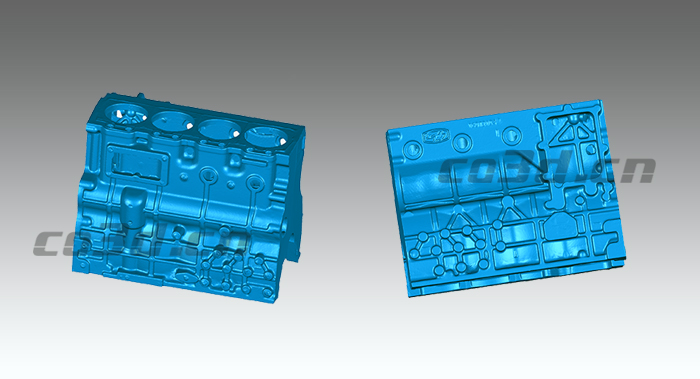

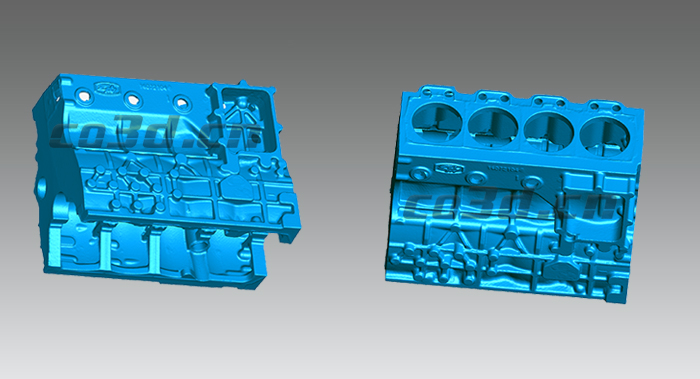

Car engine block STL diagram

Car engine block STL diagram