Auto parts reverse design

Automobile independent brand and technological innovation require parts and components as the basis. Independent innovation of parts and components is also a strong driving force for the development of the vehicle industry. Each part has the importance of existence in the whole vehicle, and it needs to constantly innovate independently. Therefore, it uses 3D scanning technology to collect parts data for processing and product appearance and surface design.

Military vehicle renderings

Practical problems

Customers need to scan more samples, different parts, high scanning accuracy requirements, reduce errors in use, and the completion time is short. Because the traditional scanning method manifests its deficiencies in the operation process, the process coefficient is large, the time period is long, and the cost is high. Therefore, it is necessary to find a more convenient way to solve the problem. The new technology 3D scanner can provide a complete solution and provide data basis and support for later processing.

Scanning scene of military vehicle accessories

Co3d solutions

The scanning device is a hand-held three-dimensional scanner HOLON751. The logo point cooperates with the self-developed scanning software to have ultra-high scanning accuracy and working efficiency. The handheld design is extremely easy to carry, the operation process is flexible and convenient, the laser line harness has multiple scanning speeds, and multi-mode switching High scanning accuracy, strong stability, and wide application fields.

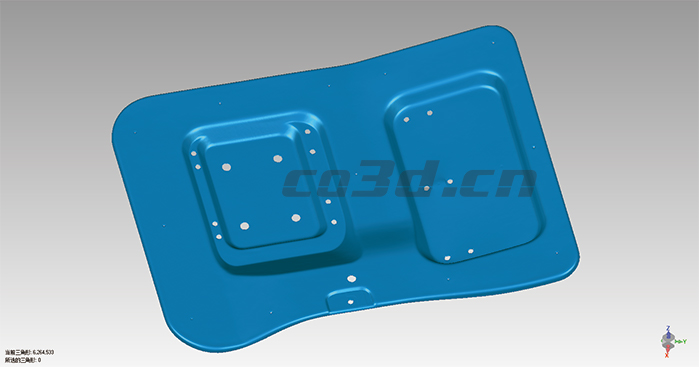

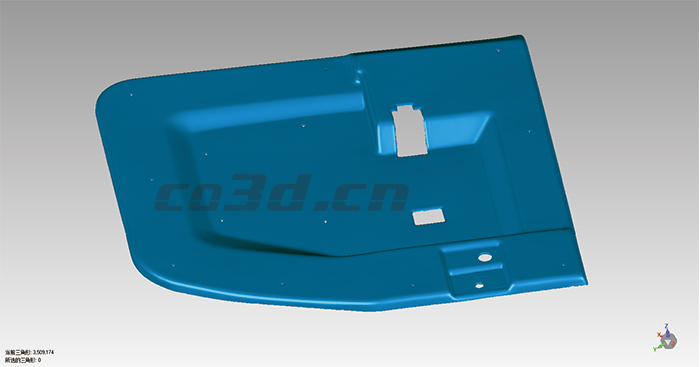

Military vehicle parts STL data chart

Military vehicle parts STL data chart

Use the hand-held three-dimensional scanner HOLON751 to scan car parts one by one, and quickly obtain high-precision three-dimensional point cloud data for each part. Import into the 3D software to optimize the point cloud data, and finally import into the reverse design software to model the data in reverse drawing. Using the handheld 3D scanner HOLON751 to successfully solve customer problems, easily complete data collection, you can reverse design the data for design and processing, improve work efficiency, and speed up development.

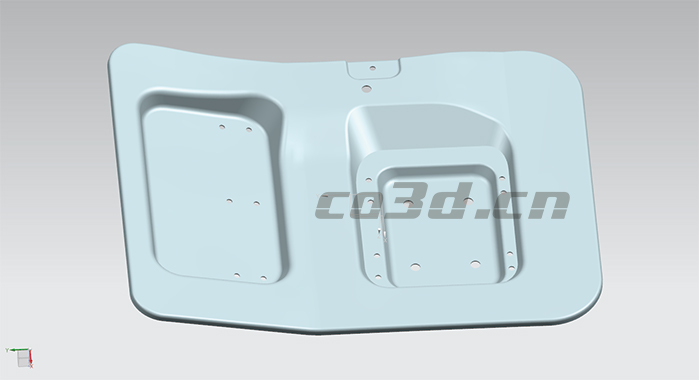

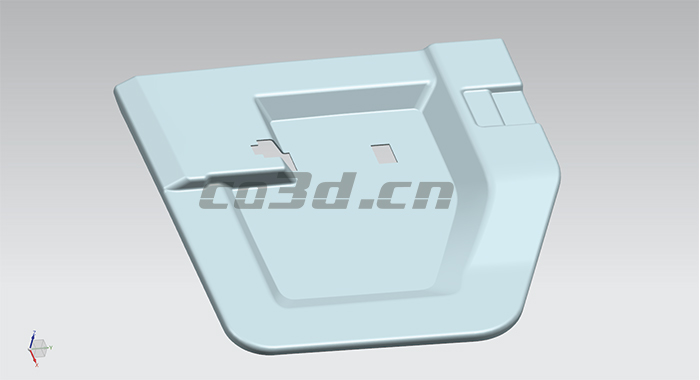

Reverse data graph of military vehicle parts

Reverse data graph of military vehicle parts