Three-dimensional inspection of automobile inspection tools

The inspection tool is a simple tool for industrial production enterprises to control various sizes of products, improve production efficiency and control quality, and is suitable for mass-produced products. It replaces professional measurement tools and becomes a special dimensional error detection tool. Because it is a detection error tool, it has high requirements for its own design and production, and no large errors can occur, resulting in inaccurate product detection and prone to problems in use. This requires a comprehensive inspection of the inspection tool, comparative analysis of whether there are any defects.

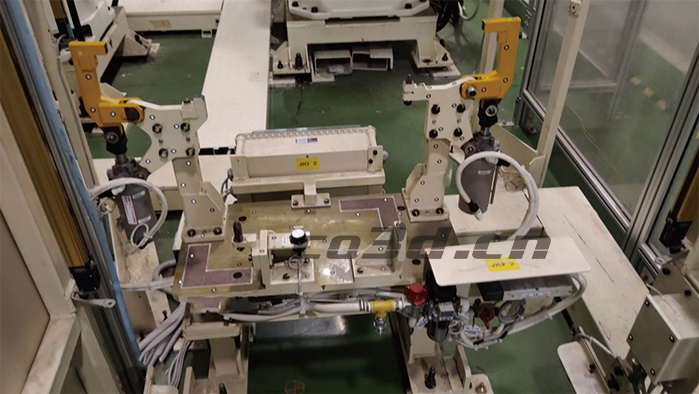

Scanning scene of car inspection tool

Practical problems

The customer is an automobile manufacturer, and the inspection tool is mainly used to detect whether there are errors in auto parts. Now the demand is to detect the possible problems of the inspection tool to make improvements to avoid affecting the automobile manufacturing. The new three-dimensional detection method has the advantages that the traditional detection method does not have. The scanning speed is fast, the measurement accuracy is high, the detection error is shortened, the operation is convenient, and the work cycle is short.

Scanning scene of car inspection tool

Co3d solution

For the customer's question, the proposed solution is: handheld 3D scanner 751. Because the hand-held scanning is convenient, the operation is simple, one person can easily scan, the mobility is convenient, the laser line scan mode is many, and it can accurately collect data for deep holes, dead angles and details.

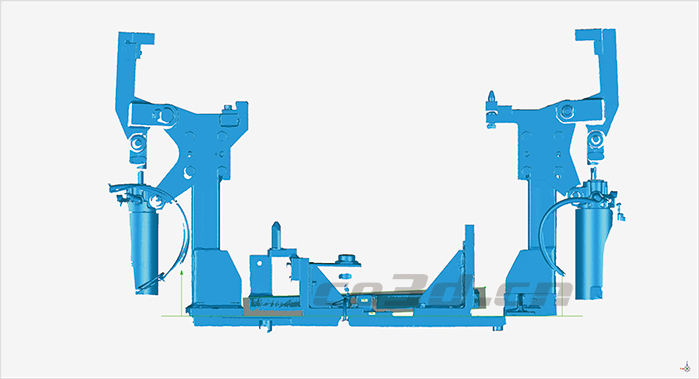

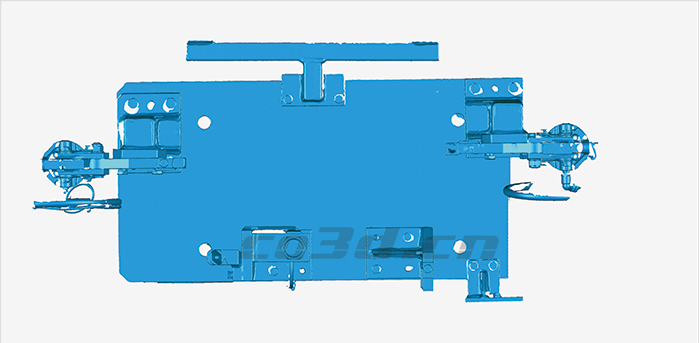

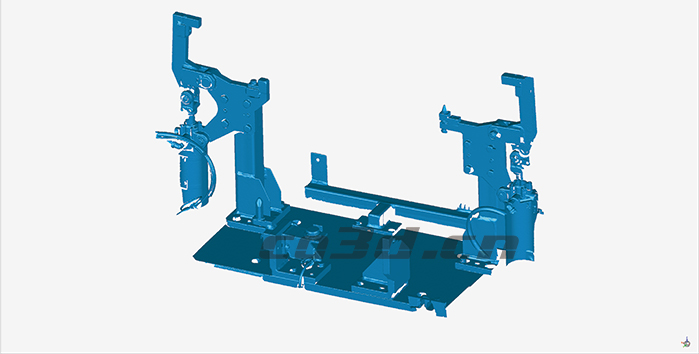

STL data chart of automobile inspection tool

Scanning operation process: First, the identification point is pasted for positioning and splicing. Then use the hand-held 3D scanner HOLON751 to comprehensively and quickly scan the inspection tool to obtain high-precision data, import the software for data post-processing, and then import the 3D detection software and the original data for data detection and analysis, and export an intuitive and simple data comparison analysis report. The customer clearly sees the problems of the inspection tool in the inspection report, and can make subsequent improvements to successfully solve the problems facing the customer.

STL data chart of automobile inspection tool

STL data chart of automobile inspection tool