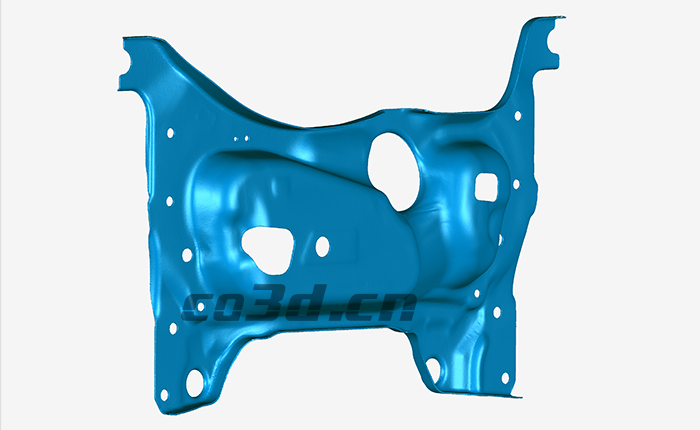

Automotive stamping parts

Stamping parts are mainly formed by stamping die processing, and some errors may occur in the production process. Customers who want to inspect automotive sheet metal parts need to use advanced measurement tools to determine whether the sheet metal parts are deformed or damaged through accurate three-dimensional measurement and high-precision data, and perform deformation analysis to make repairs Program.

Field scan

Practical problems

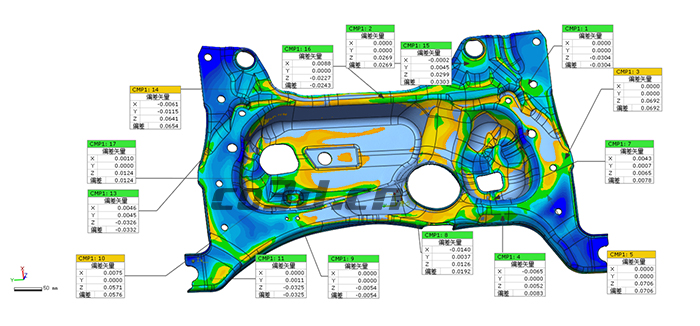

Because the customer needs to inspect the automobile sheet metal parts, the hole positions and parts are compared with the original digital and analog to get the corresponding deviation. It is required to obtain high-precision data quickly and comprehensively, and complete the inspection with high efficiency.

STL data graph

Solutions | Co3d solutions

Use HuaGuang handheld 3D scanner HOLON751 to scan sheet metal parts to obtain high-precision data. Holon751 has a total of 20 laser beams, the scanning accuracy is up to 0.02mm, and the scanning speed is fast. The deep hole mode is suitable for scanning deep holes and dead corners. The ultra-fine scanning truly restores the size of the subtle data.

The acquired data is imported into the inspection software and aligned with the original digital model for comparative analysis, to determine whether the deviation value is within the tolerance range, and easy-to-understand inspection reports can be exported to help customers analyze existing problems. Import the data into the reverse engineering software to optimize the design.

Comparative analysis chart