Three dimensional inspection of automobile engine

The engine is a machine that provides power for the machine. It is the heart of the machine. It will affect the power, economy and environmental protection of the machine. It is a very core component. Therefore, no matter how good the appearance design of the machine is, it is not as important as having a good engine. Whether in terms of design, manufacturing, process, performance and control, they are constantly improving. Now the focus is not only on machine power, but also on aspects related to energy consumption, exhaust emission and environment. Customers now need to use a three-dimensional scanner to obtain the complete three-dimensional data of the engine for quality inspection and R & D data analysis.

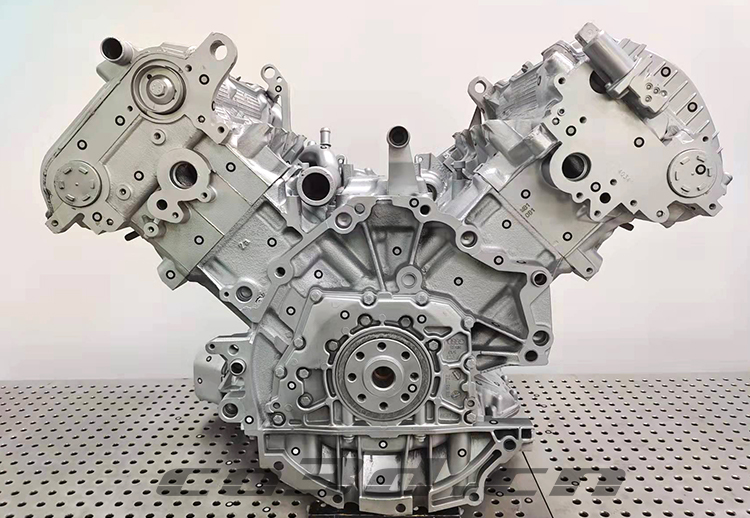

Physical drawing of automobile engine

Practical problems

Automobile engine has many and precise components, large and bulky, which is very inconvenient to move. The surface is complex, there are many holes, and the use of general scanners is not easy to lack the undulating surface, the obtained data is incomplete, and the detection error is too large, which consumes a lot of time and cost, and the efficiency is low, which can not meet the needs of customers.

Physical drawing of automobile engine

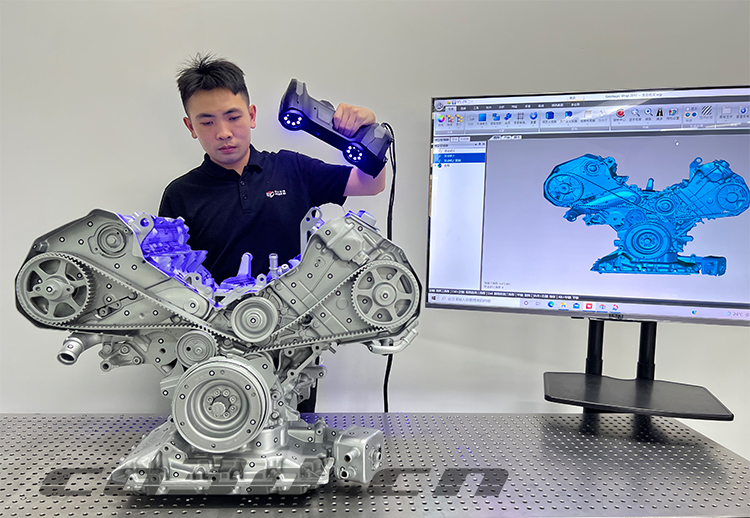

Solutions

According to the characteristics of the workpiece and the needs of customers, Huaguang 3D technical engineers put forward solutions. They use the handheld laser 3D scanner Holon B71 to scan the undulating surface in fine mode, with an accuracy of up to 0.02mm. The single line deep hole mode scans the hole position, which can easily obtain high-precision complete 3D data, with simple and fast operation and high efficiency.

Import the scanned three-dimensional data into the comparison and detection software, conduct comparison and detection analysis with the original CAD model, and obtain a simple and understandable comparison and detection report to meet the needs of customers.

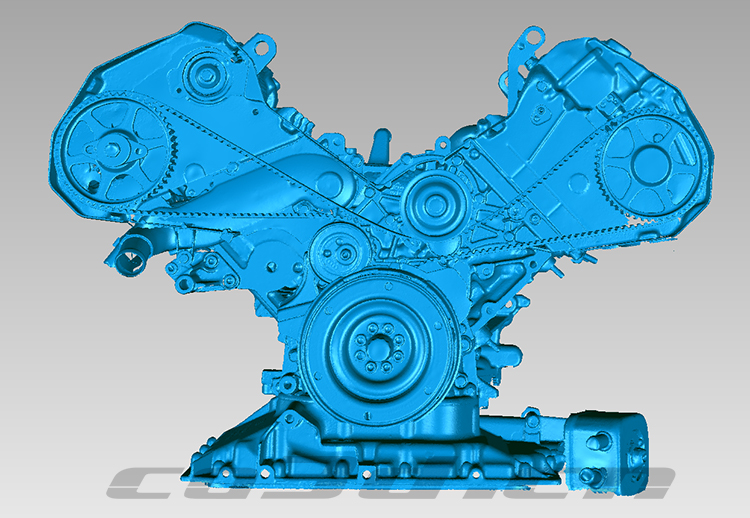

STL data diagram of automobile engine

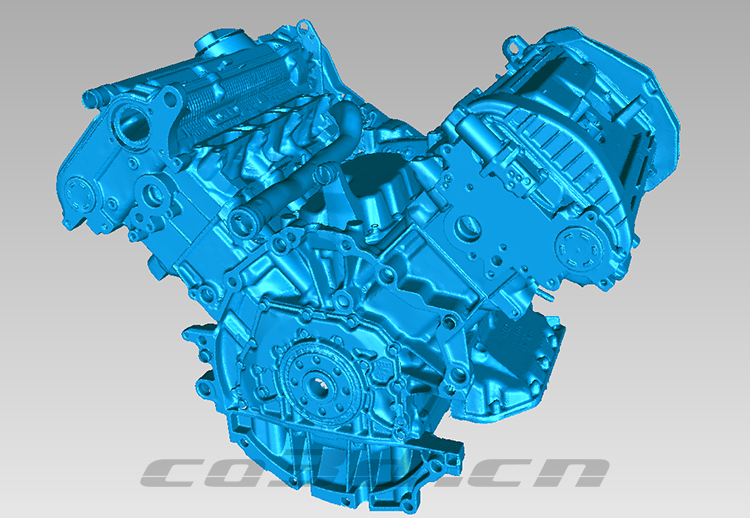

STL data diagram of automobile engine