Three dimensional inspection of automobile sheet metal parts

The sheet metal parts of the automobile generally refer to the metal shell of the automobile, which is usually made of steel plate. On the basis of ensuring a certain strength, it is the basic requirement to reduce the weight as much as possible. In addition to protecting and beautifying, automobile sheet metal parts are also the main carrier for automobile to bear gas resistance. Therefore, the quality and life of auto sheet metal parts not only affect the appearance of the car, but also increase the negative force of air on the car due to quality, deformation and other reasons, reducing its economy.

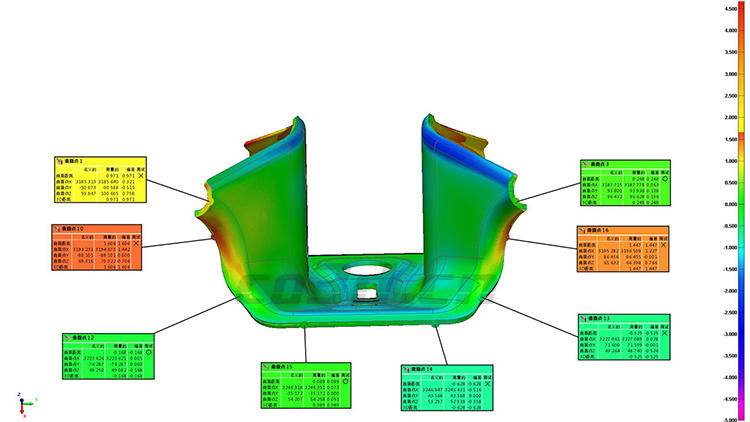

In order to measure the 3D data of sheet metal parts, a well-known automobile parts manufacturer used the acquired 3D data to compare with the original data, and then obtained a very intuitive 3D detection chromatogram. According to the comparison report, the overall deviation between the actually produced sheet metal parts and CAD drawings can be clearly seen, and the error of the workpiece can be clearly known.

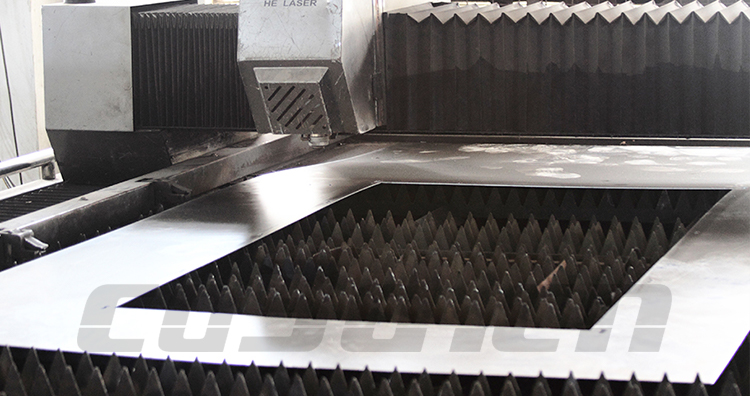

Field Drawing of Automobile Sheet Metal Parts Processing

Field Drawing of Automobile Sheet Metal Parts Processing

Practical problems

1. Detect the overall data of automobile sheet metal parts, the details of bending dead angle and the accurate position information of hole location

2. The machining surface of automobile sheet metal parts is complex, with large deformation, and the groove shapes of each face are different, which is very complex. It is difficult to determine the uneven assembly clearance of sheet metal parts in the later stage, and the height deviation of the fitting surface of sheet metal parts.

In view of the problems faced by customers, Hualang 3D technical engineers use a hand-held 3D scanner HOLON 771 (fast scanning of auto sheet metal parts to obtain high-precision 3D data)+3D detection software (comparison of auto sheet metal parts and product digital models)

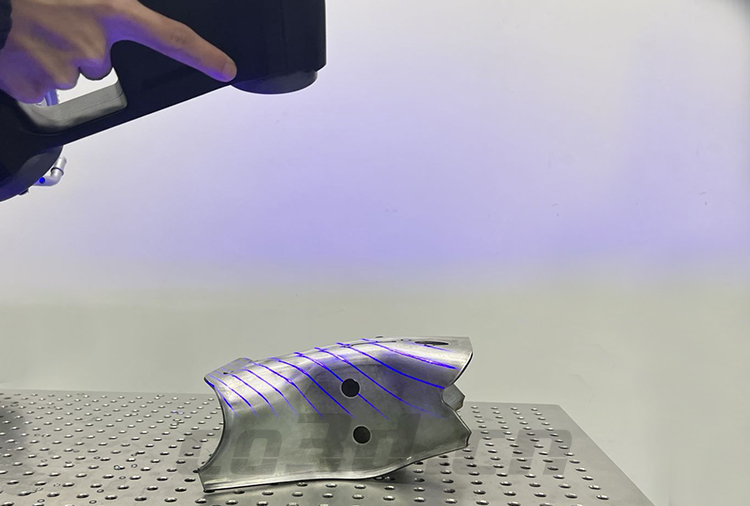

Scanning site map of automobile sheet metal parts

Scanning site map of automobile sheet metal parts

solutions

1. Auxiliary preparation before measurement

Sticking marker points: make the acquired data locate and splice in the scanning software.

2. 3D scanning

The hand-held 3D scanner HOLON 771 has a fast scanning speed. It takes only 2 minutes to obtain 3D data of sheet metal parts, and the data accuracy is as high as 0.02mm. Industrial blue laser+industrial intelligent design is adopted to collect sheet metal data quickly and with high quality. Import the 3D data of auto sheet metal parts into the 3D detection software for processing and obtain the detection analysis report of sheet metal parts with one key.

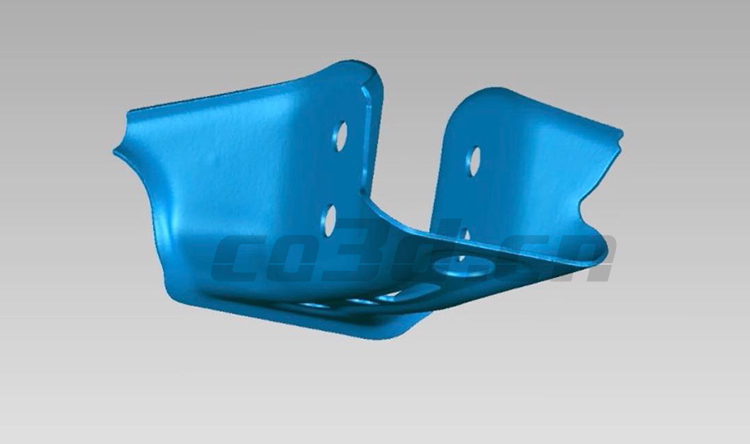

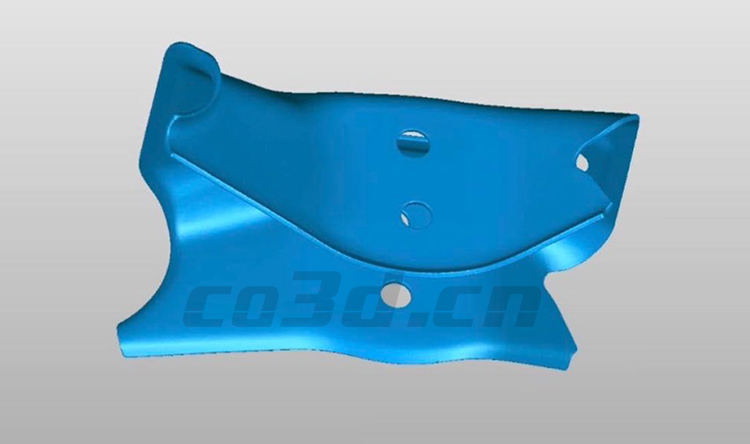

STL Data Diagram of Automobile Sheet Metal Parts

STL Data Diagram of Automobile Sheet Metal Parts

Comparison Inspection Diagram of Automobile Sheet Metal Parts