Three-dimensional inspection of automobile door mold

According to statistics, automobile molds account for one third of the total in China's mold industry, and more than 90% of the parts manufactured in the automobile industry need to rely on molds for production, which is enough to find that automobile molds occupy an important position in the automobile manufacturing and mold industry.

Under the premise of many automobile structures, the automobile mold will also become complex and changeable. In the early manufacturing and later testing of the mold, the major automobile mold manufacturers choose to use Hualang high-precision handheld 3D scanner to provide intelligent transformation for the manufacturing and testing of the mold in order to carry out rapid and efficient testing

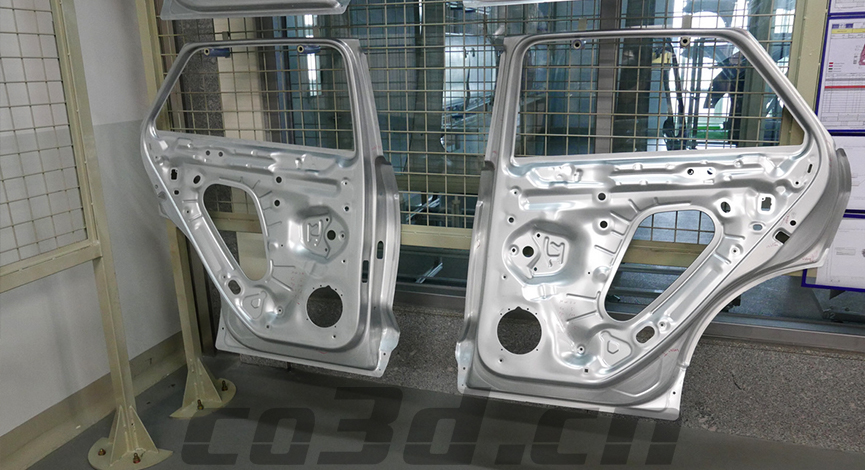

Three-dimensional scanning physical image of car door

Three-dimensional scanning physical image of car door

面临的问题| Practical problem

The traditional mold inspection is highly dependent on manual work. The master's experience and technology have become an important standard to judge whether the mold is qualified. This not only has extremely low efficiency, but also causes

For the complex and changeable mold types, a detection method with high compatibility is needed to deal with the difficulties in the detection of various molds.

As the front end of automobile production, the precision of automobile mold directly determines the quality of subsequent automobile products. Therefore, mold inspection needs very high data precision support.

Three-dimensional scanning scene of car door

Three-dimensional scanning scene of car door

Three-dimensional scanning scene of car door

解决方案| Holon solutions

Hualang handheld 3D scanner takes into account the flexibility and efficiency of the handheld and the high precision of the camera to provide great convenience for the early data acquisition of the mold, and quickly and efficiently obtain the overall 3D data of the car mold. (0.01 single maximum accuracy, 0.02 maximum resolution)

Compatibility under various scanning modes. The scanning mode can be adjusted according to the mold characteristics to achieve the best scanning effect in the shortest time and save more time and cost for subsequent detection. (Scanning speed: 202000 times/second)

A variety of laser forms are merged to deal with 3D data that are difficult to capture positions such as the dead corner groove surface inside the mold. (parallel laser/cross parallel laser/single line laser)

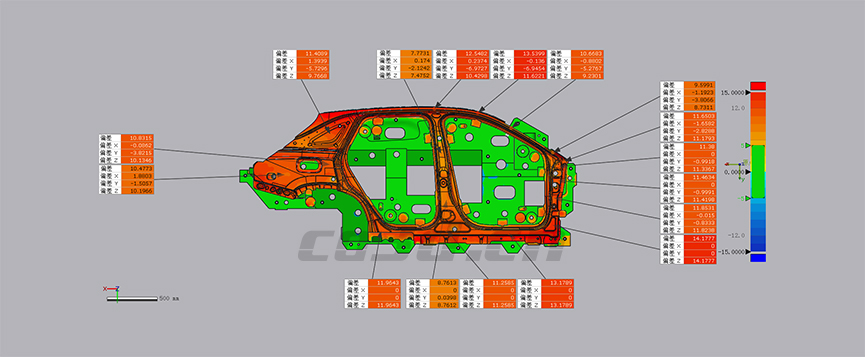

Comparative inspection diagram of car door

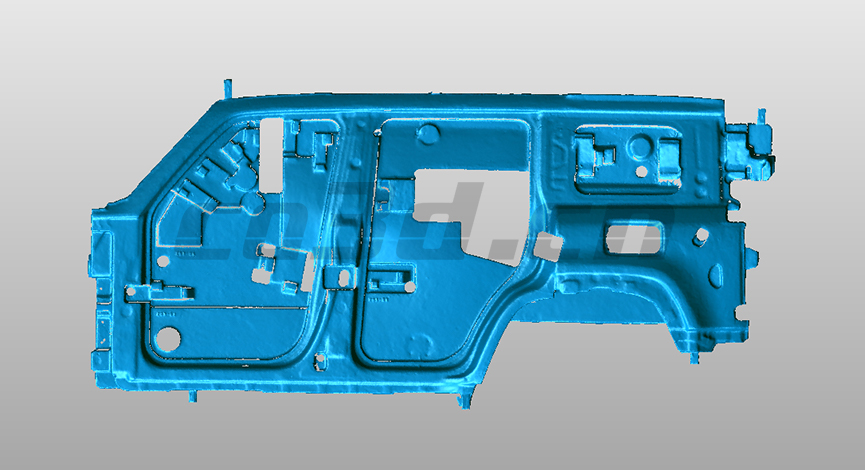

Car door STL data diagram