The motor casing is insulated and has a protective effect (preventing dust from entering the motor and injuring people) and component installation support. It can also help dissipate heat and reduce noise and vibration, effectively protecting the normal operation of the motor

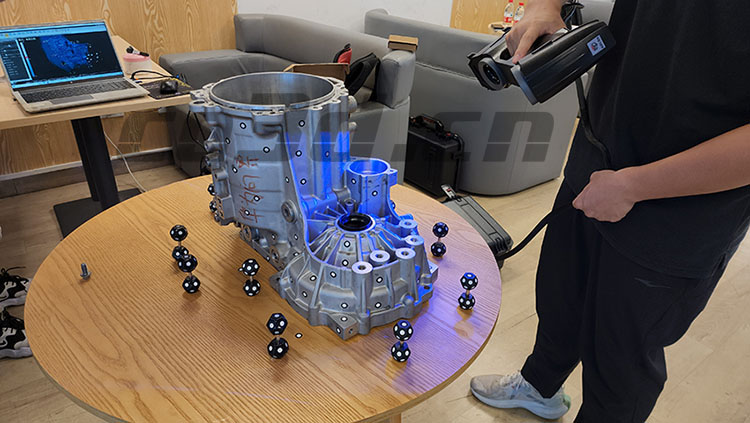

Scan the scene

Practical problems

Customers need to perform 3D scanning on the motor casing to obtain 3D data for reverse design. If the accuracy of the center hole and shaft assembly of the motor casing does not meet the requirements, it will affect the service life of the motor. The precision requirements are high, and the workpiece surface is irregular with many holes. Traditional measurement methods are inefficient, costly, and the data is not accurate enough to accurately detect.

Scan the scene

Co3d solution

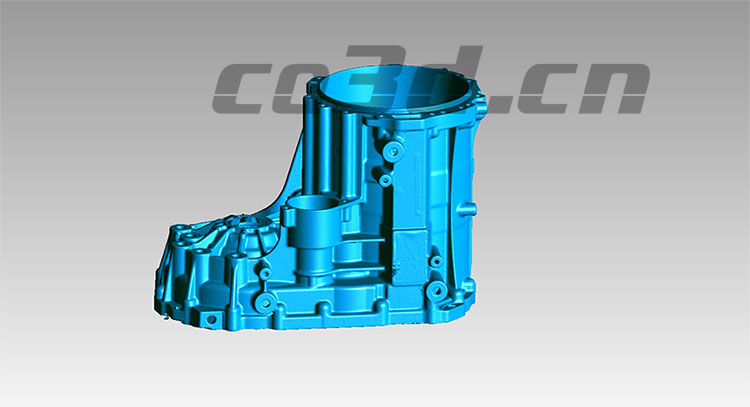

In view of the problems faced by customers, Hualang 3D engineers use HOLON B71 to carry out 3D scanning to quickly obtain high-precision 3D data of electromechanical enclosure. The scanning speed is up to 2.02 million times/second. The maximum precision of a single frame can reach 0.01mm in the precision mode. The scanning speed is fast and the precision is high. The scanned 3D data can be imported into the reverse design software (converting the motor enclosure point cloud data into Triangle mesh surface data) for reverse design. Improve work efficiency, reduce development cycles, and address customer needs.

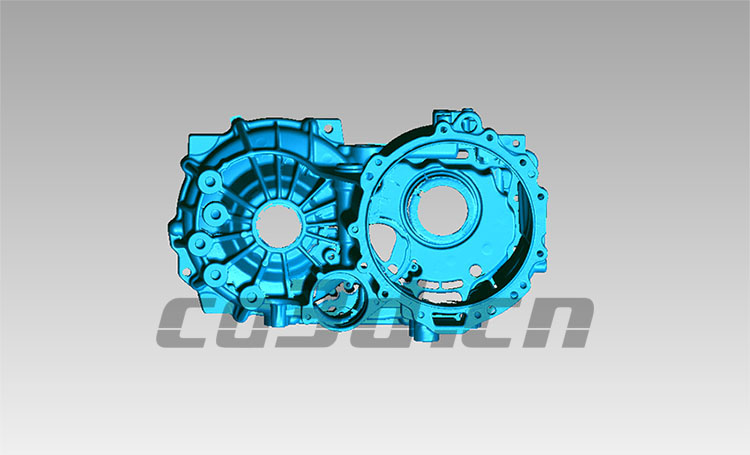

Motor casing STL data diagram