Reverse design of turbine blade in fighter jet

Guizhou aircraft parts manufacturing enterprises to use 3D scanner to scan Huaguang wear aircraft turbine blade, the blade of turbine blade is the carrier to achieve energy conversion of the fuel gas in the primary factor in determining the performance of a turbine blade, aircraft design requirements are very high.

Practical problems

1 in view of the complexity of the blade edge curvature, the 3D scanner was used to detect the blade of the aircraft engine.

2 the traditional method of measurement data acquisition density is insufficient, because the blade surface is irregular curved surface, and the scanning precision of 3D scanner is very high.

CO3D solutions

Turbine blade structure design is complex, tedious process, to complete design of turbine blade, must do detailed 3D scanning of turbine blade, the 3D scanner to scan the turbine blade model to obtain 3D data with high precision, improve the design efficiency and design personnel, to ensure the accuracy of the CAD design, shorten the product development cycle. Huaguang 3D technology engineer according to the airline's face, the use of the proposed solution: 3D scanner HL-3DS+ (3D motor parts of fast data acquisition of high precision) + reverse design software (based on 3D data with high precision 3D scanner in two design), to speed up the production of aircraft turbine blades.

The characteristics of multifunctional 3D scanner HL-3DS+ products: extrapolation method of multi frequency phase shifted grating: uniform fringe projection, point cloud data with high precision, noise free data, hardware system of small size, less area, no noise, easy assembly and disassembly, fast scanning speed: less than 3-5 seconds can get millions of data points, high efficiency (can also be according to customer demand for customized system), single scanning precision can reach 0.01mm, eliminating the common 3D scanner multi angle scanning not on the question of the cumulative scanning precision is very high, a single machine can complete 4m workpiece scanning, data distortion, and other steps, fringe scanning mode, easy adjustment, suitable for various requirements of the workpiece.

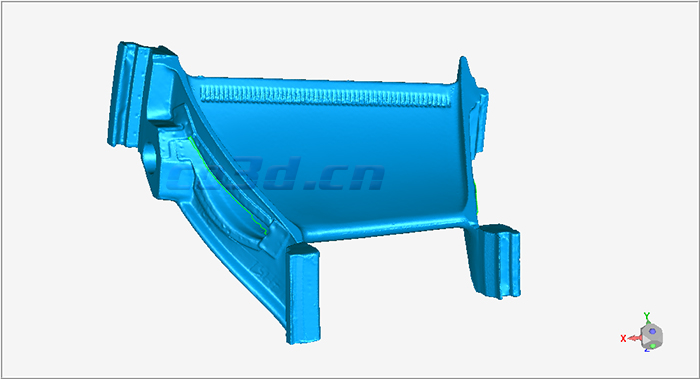

Turbine blade STL data chart

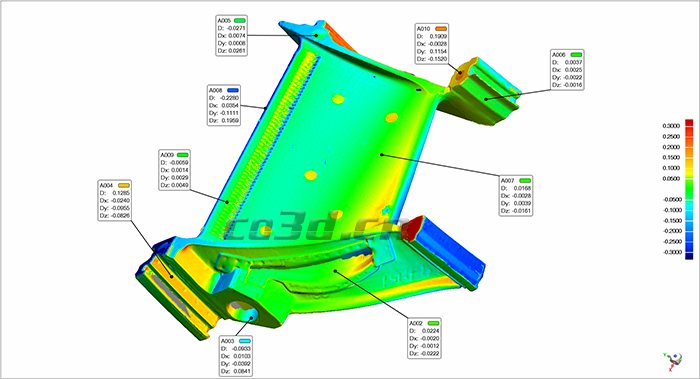

Turbine blade contrast detection chart

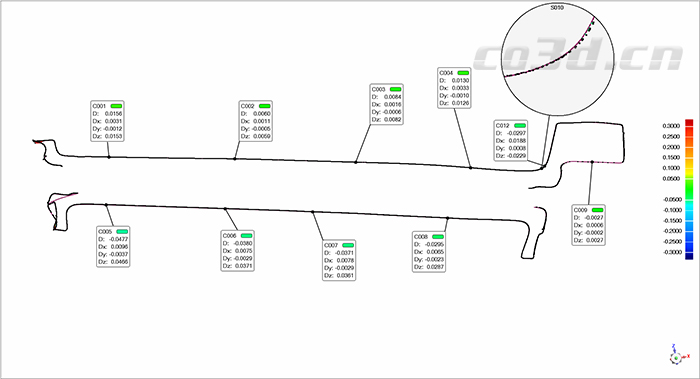

Turbine blade section