3D scanning of aircraft tires and wheels

Aircraft tires and wheels are important components of the aircraft as a whole. The design of tires and hubs is mostly complicated. The hubs are highly matched with the tires and the axles of the aircraft.

Aircraft tire material black wheel material has high reflective characteristics, ordinary 3D scanner can not directly scan, you need to do powder processing before you can obtain data, the tools and techniques used for 3D inspection have high requirements. Recently, a manufacturer specializing in aircraft companies has found Huaguang. I hope that we can recommend a suitable 3D scanning solution and purchase equipment.

Scanned object: aircraft tire

Aircraft tire scanning scene

Inspection requirements: measuring the size of the car hub, equipment hole position, tire wall thickness and overall model

Recommended solution: HOLON 760 laser handheld 3D scanner + 3D inspection software

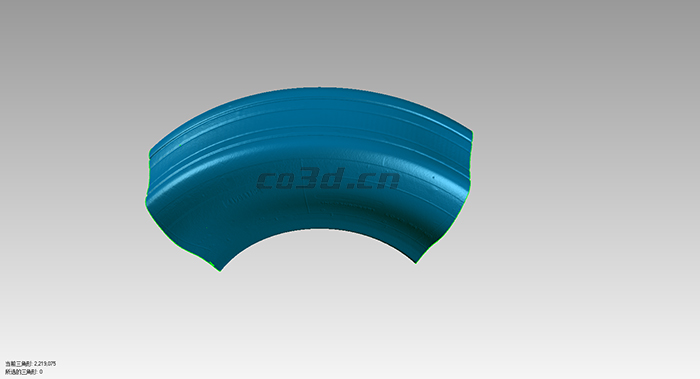

Automotive tire scanning local STL data map

Detection step

Step 1

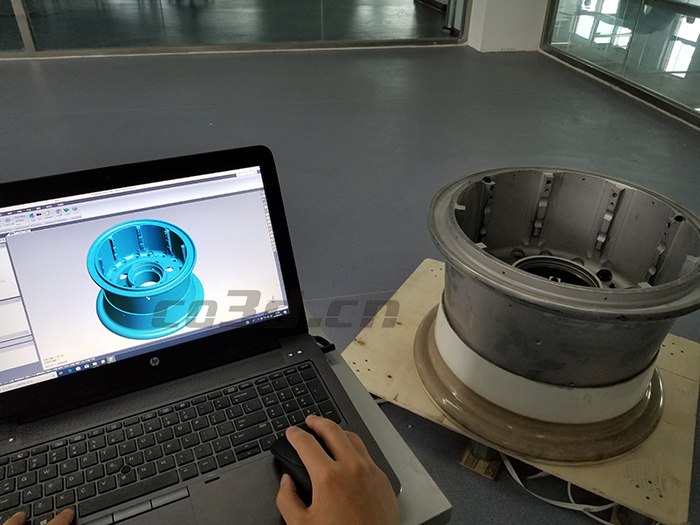

Use the HOLON760 laser handheld 3D scanner to perform three-dimensional scanning of the aircraft hub (no need to dust) to obtain full-size 3D scan data. The operation is simple, the scanning speed is fast, only 10 minutes (in the case of high reflection on the surface of the car hub), and the data is displayed on the PC side in real time during the scanning process.

Aircraft wheel scanning field data

Step 2

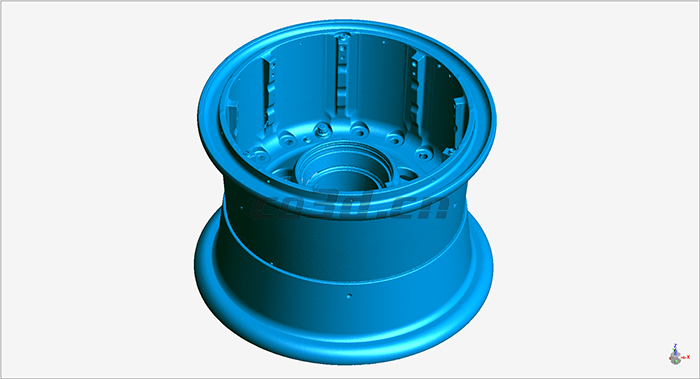

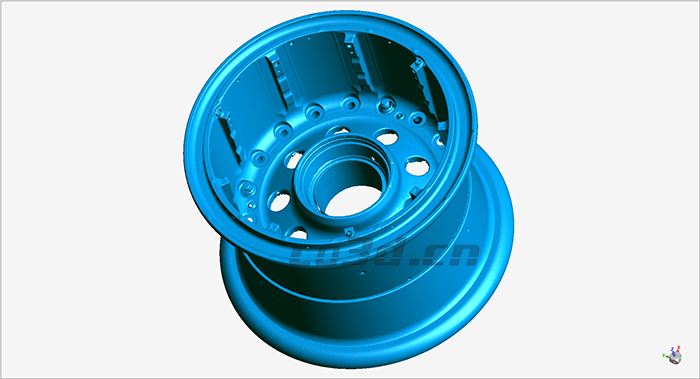

Import the scanned 3D data into our Huaguang 3D self-developed 3D inspection software, mark the points to be measured, and automatically generate corresponding measurement data.

Aircraft wheel STL data chart

Aircraft wheel STL data chart

Case summary

Traditional aircraft tire scanning hub inspection uses three-coordinate and traditional manual measurements, but these methods inevitably have varying degrees of problems.

The first type, the equipment cost is expensive, and most of the workpiece inspection is impossible in the field environment to measure in the laboratory environment;

Second, the traditional quantity is low and the efficiency is low. The user needs to invest a lot of time to obtain the scanned data and waste too much human and material resources;

Shaped 3D According to the user's needs, the handheld laser 3D scanner is recommended, which has the scanning efficiency and flexibility. It does not need to spray powder during scanning. It is not limited by the environment and sample specificity, and the data precision is high. It is especially suitable for aircraft wheel detection and measurement. Reverse tire repair, product development and design. The solution is well suited to the customer's requirements and has the following advantages:

1, HOLON760 has good portability, the weight of the host is only 0.87KG;

2, the operation is convenient and simple, you can learn without professional background, and master the scanning skills;

3. It is not restricted by the object to be measured, and can obtain full-size 3D scan data without spraying powder;

4, a wide range of applications, can be used for batch testing

5, non-contact measurement, fast and accurate;