Large aircraft engine inner wall 3D scanning case

A large international airline invited us to perform three-dimensional scanning on the inner wall of a large aircraft engine to obtain high-precision three-dimensional data, so as to achieve cost-saving and time-saving modeling and repair of the inner wall of a large aircraft engine. Reduce the difficulty of later mold opening and repair work.

Practical problems

1. The large aircraft engine has a large inner wall and many curved surfaces. The customer's requirements for the accuracy of the 3D data on the inner wall of a large aircraft engine are very high to ensure that the accuracy is up to standard.

2. The curvature of the outer surface of the large aircraft engine is difficult to measure by manual. The customer is required to obtain complete and accurate data in a short period of time, so that the follow-up work can be carried out quickly, ensuring that the later repair modeling can proceed smoothly. Reduce costs and save time.

CO3D solutions

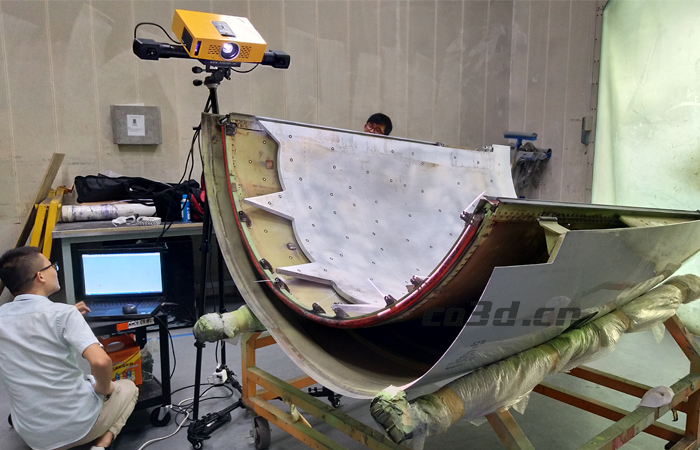

According to the customer's requirements and problems, the 3D technical engineer proposed a solution: using the newly developed ultra-large-format scanning equipment, the camera-type 3D scanner W3000 quickly and accurately acquired the 3D data of the large aircraft engine inner wall will be scanned. The 3D data import software fits the STL triangle mesh surface and imports the 3D design software for modeling and repair. The product structure design and improvement have improved efficiency, and the follow-up work has been carried out quickly, which not only saves time but also controls costs, and successfully solves the problems faced by customers.

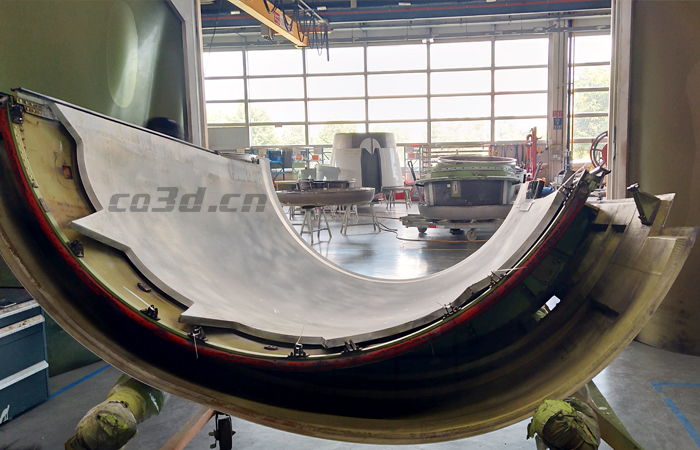

On-site physical map of aircraft engine inner wall

Large aircraft engine inner wall scanning site map

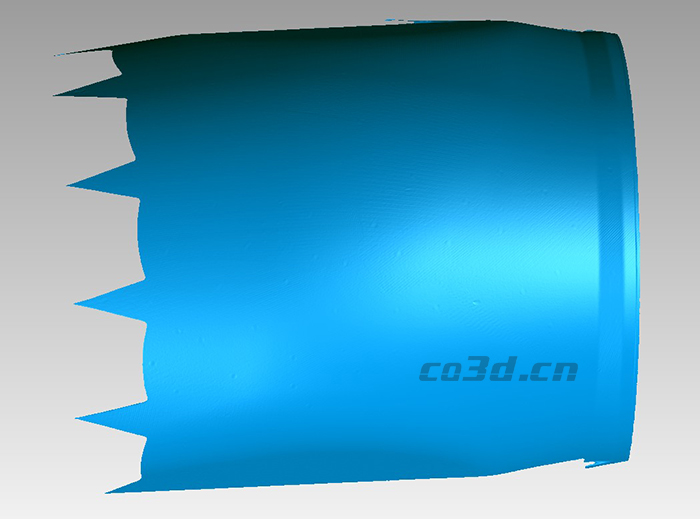

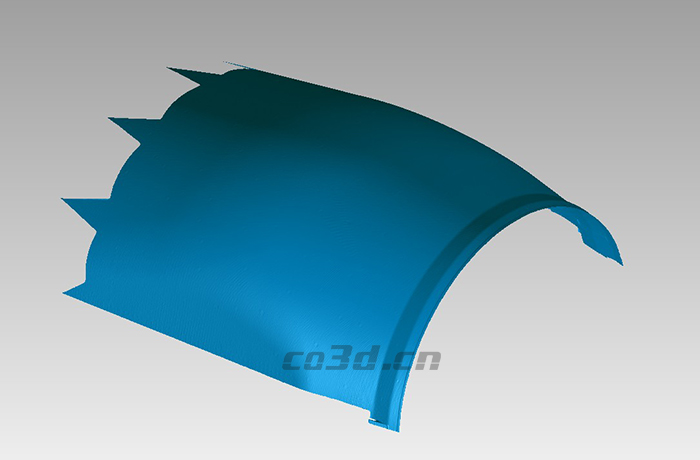

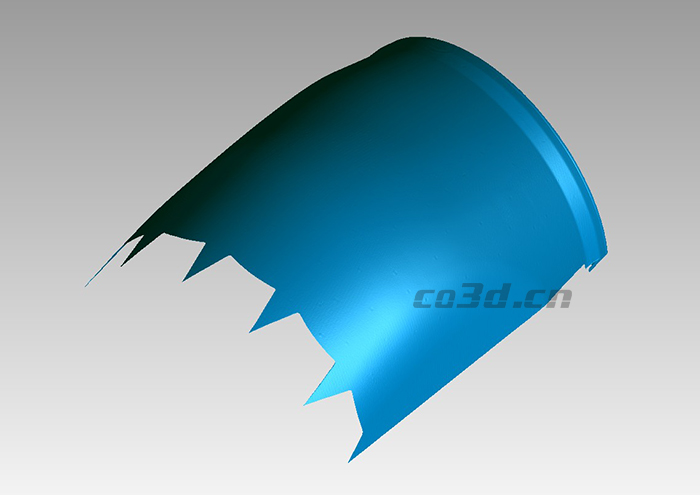

Large aircraft engine inner wall STL data map

Large aircraft engine inner wall STL data map

Large aircraft engine inner wall STL data map