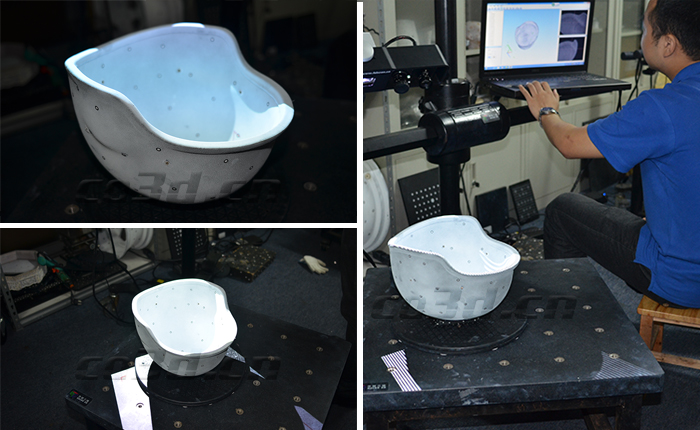

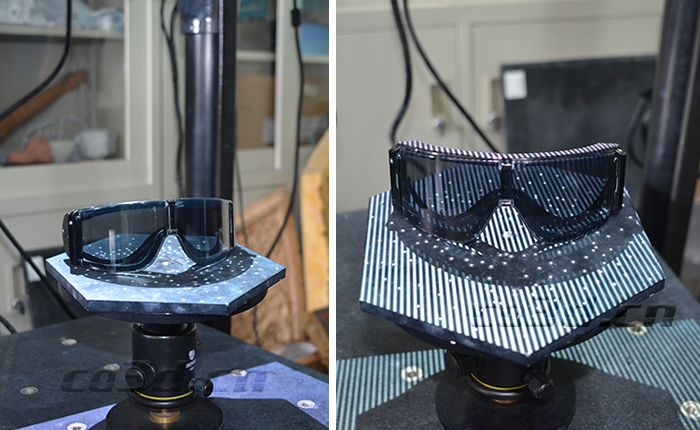

Military space helmet goggles scanning

Huaguang engineers use the 3D scanner “3DMV+” to scan the military helmet goggles in three dimensions. Customers need to use scanning to obtain high-precision 3D data of military helmet goggles for microwave digital transmission equipment applications and better development and improvement. .

Practical problems

The traditional measurement method has insufficient data acquisition density (insufficient data volume). The internal structure of the goggles is relatively complicated, and the surface and curvature of the military helmet goggles cannot be accurately measured. In the later stage, the reverse mapping cannot be reversed. The workload is large, the efficiency is low, and the accuracy is low. Not high, can not meet the requirements of customers, and it is more difficult to use reverse design for product R&D design.

Co3d solutions

In order to shorten the development cycle and reduce the research and development cost of the PLA helmet goggles, Huaguang 3D proposes a solution based on the problems faced by customers: using industrial grade 3D scanner (3DMV+) to obtain 3D data of helmet goggles. The three-dimensional scanner has the characteristics of extremely fast scanning speed, high precision, simple operation and strong stability. During the scanning process, the software automatically stitches the 3D data through the marker points. In less than 30 minutes, the 3D data of the helmet goggles is completely acquired. Customers can import the scanned 3D data into the software to fit the SLT triangle mesh surface and import it into the 3D design software for reverse design. The secondary design and improvement of the product improves efficiency and saves costs.

Military helmet physical map

Military helmet physical map

Military helmet physical map

Military helmet STL data graph

Air force badge STL data graph

Air force badge rendering

Military helmet rendering