The head of a Boeing airplane is in reverse design

A customer is doing the aircraft simulation equipment, application of teaching body within the major airlines plane, need to get high precision three-dimensional model of Boeing aircraft nose, uh guano engineers use our new product - W3000 HL, rapid and accurate to obtain the 3 d data of the Boeing aircraft nose, meet airlines on its new students training and the demand of the old employees retraining.

Practical problems

1. The large size of Boeing aircraft, the traditional method of measurement is too low and the precision is not high, it is difficult to design and model the reverse design. Waste a lot of human resources.

2. The curvature of the outer surface of the aircraft is difficult to be measured by labor. The customer needs to obtain the accurate data of the aircraft head of the Boeing series, which requires the equipment with high measurement accuracy.

CO3d solutions

In order to shorten the modeling period, reduce the cost of research and development of aircraft nose uh guano 3 d according to the problems facing the customers, put forward the solution: use our new product of industrial-grade 3 d scanner W3000 Boeing aircraft nose to obtain the 3 d data. The 3d scanner has the characteristics of high scanning speed, high precision, simple operation and strong stability. During the scan, the software automatically spliced the 3d data through the logo point, and quickly obtained the 3d data of the Boeing aircraft's head. The customer can import the 3D data of the scan into the software to fit the SLT triangular mesh surface and import the 3D design software to carry out the reverse design. The design and improvement of product structure improve efficiency and save cost.

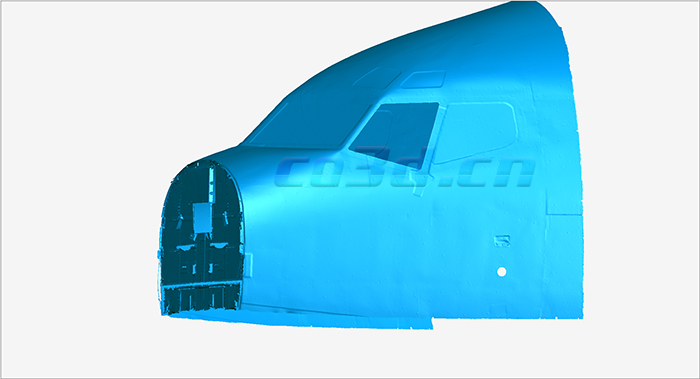

The first scene of the Boeing series

Boeing series aircraft nose scan site map

Boeing series aircraft nose scan site map

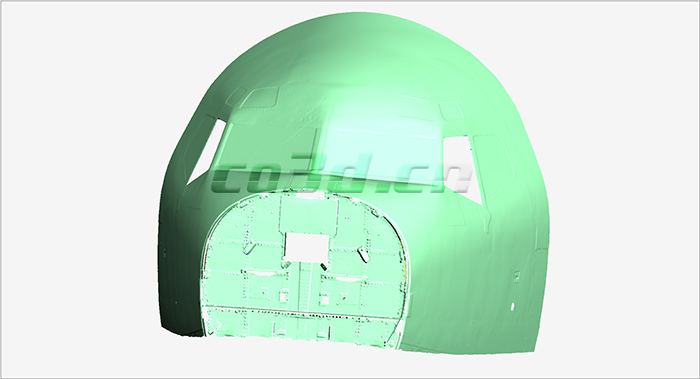

The Boeing series of aircraft nose points

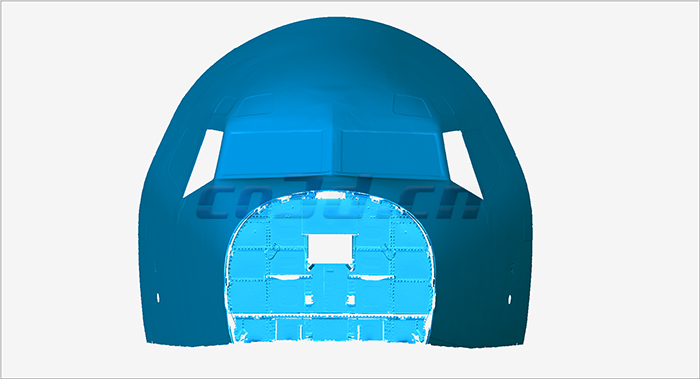

Boeing series aircraft nose STL data graph

Boeing series aircraft nose STL data graph