Three dimensional inspection of aircraft exhaust hood

As the core power component of aircraft, the exhaust hood of aircraft engine plays an important role. At the same time, it can protect the engine and surrounding pipeline accessories, including engine, circuit, oil circuit, braking system and transmission system, so as to fully protect the normal operation of the aircraft.

Practical problems

1. The aircraft exhaust hood is made of titanium alloy. Several typical failure forms of titanium alloy may occur in aviation engineering applications, including fretting wear, fretting fatigue, hot salt stress corrosion, hydrogen embrittlement, embrittlement of low melting point metal and contact corrosion.

2. The air intake hood of aircraft engine has the characteristics of different groove shapes and porous positions on all sides, and its structure is complex. It needs to detect fretting wear, and it needs to be accurate in every place. At the same time, the processing and testing of geometric modeling needs accurate data. For the cross-section area of airfoil, alignment, concave convex and undulating places, it needs to carry out three-dimensional measurement in a nondestructive manner, This is a challenge to the traditional measurement methods.

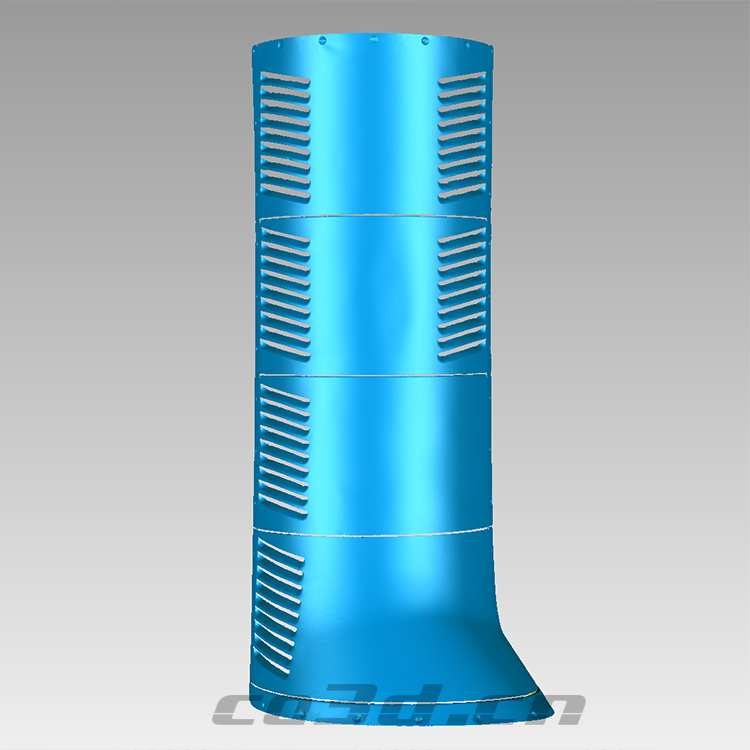

Physical drawing of aircraft exhaust hood

Solutions

Equipment used: Huaguang 3D handheld 3D scanner Holon B71

In view of the problems faced by customers, Huaguang 3D engineers put forward solutions: use the halon B71 handheld 3D scanner with the latest handheld design, light weight and easy to carry; 22 laser lines + 1 deep hole scanning + 7 fine scanning, a total of 30 laser lines. The three scanning modes can flexibly scan the variable section of the aircraft exhaust hood, and can accurately scan the concave convex surface data of the engine cover and the data of each hole position; The accuracy of data acquisition is high, and the later detection and analysis of data are carried out.

STL drawing of aircraft exhaust hood

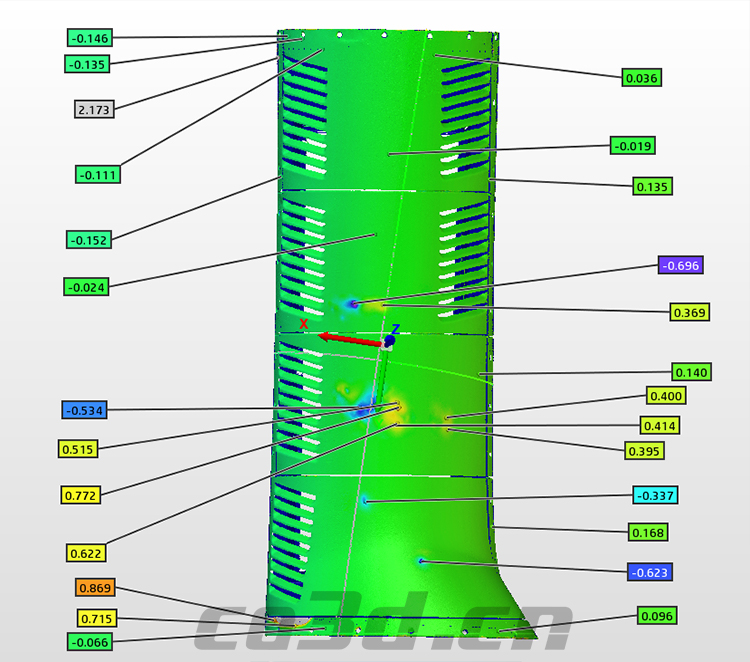

Comparative inspection diagram of aircraft exhaust hood