3D inspection of super large rigid castings

The vibrating screen equipment works by the reciprocating rotary vibration generated by the vibration of the vibrator, which produces the multi-spin type vibration of the screen surface. The work is complicated and demanding, and it is easy to wear. It requires daily maintenance and regular maintenance and overhaul to ensure production. The normal operation. A domestic customer needs to carry out three-dimensional inspection of the vibrating screen equipment. As the world's second largest casting, the vibrating screen is large and high. Scanning is a big project. After the customer has learned the data obtained by the Hualang 3D scanner. I feel very satisfied and purchase equipment.

Super large casting site real shot

Practical problems

Because the vibrating screen device is a large workpiece, it is bulky and inconvenient to move, the surface is not flat, it is covered with many small bumps with screws, and there are a few holes. The screen surface is inclined to have a curvature, and is connected with bolts of other components to form some angles. Ordinary 3D scanners are inconvenient to measure, slow and time consuming, and the data obtained is not accurate enough to meet the current needs.

Huaguang staff posted signs

Super large casting site scan

Co3d solutions

The Hualang 3D handheld 3D scanner HOLON760 and 3D photogrammetry 3DP were used. HOLON760 has high scanning speed and high precision. It can be switched to a single laser scanning mode. It is suitable for scanning deep holes and dead angles. It is easy to operate, unrestricted and has a wide scanning range. In addition, when using 3DP to scan large workpieces for measurement, it can reduce the cumulative error of 3D scan data splicing, realize fast scanning of large workpieces, and fast data processing and error reduction. Can solve problems effectively.

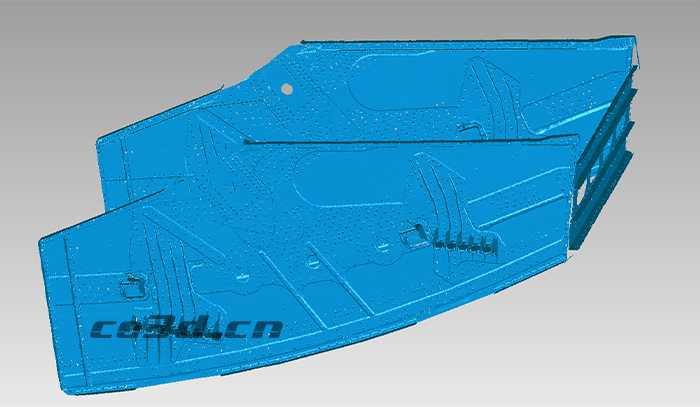

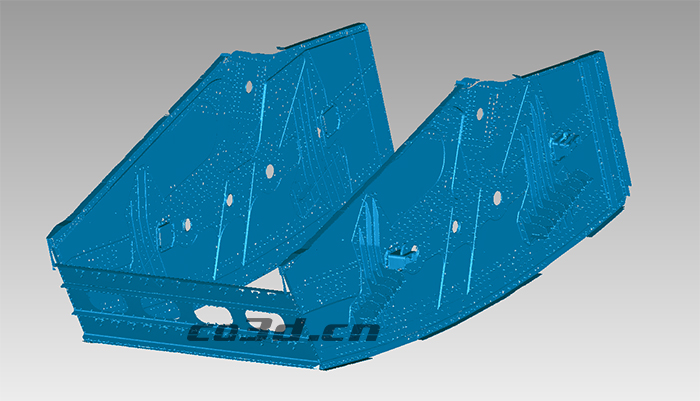

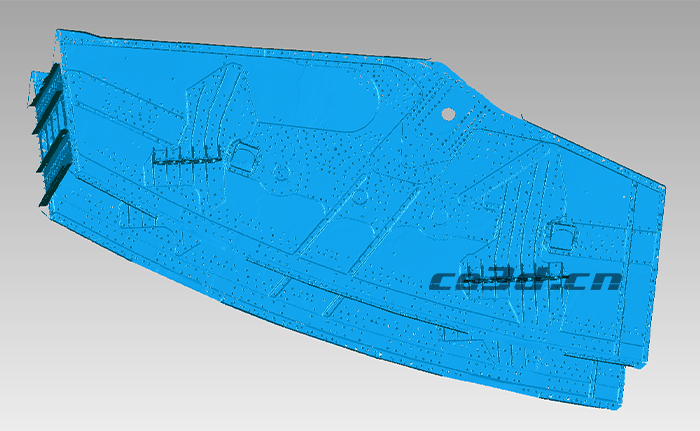

Extra large casting STL data chart

Extra large casting STL data chart

Extra large casting STL data chart