Surface defect detection of oil roller

Well-known grain and oil enterprises in China need to carry out three-dimensional inspection on the oil pressure roller. For the oil pressure roller used by the enterprise cannot operate normally, Hualang 3D provides the solution for the enterprise.

When the oil roller is operating under high temperature and high pressure for a long time, based on the working principle of the oil roller, the surface is prone to sag, resulting in uneven pressure on the overall surface of the oil roller, and the subsequent oil pressure efficiency will be greatly reduced

Three-dimensional scanning physical image of oil pressure roller

面临的问题| Practical problem

1.The oil roller body is large and difficult to detect. It is necessary to measure the slight error on the surface of the oil roller to ensure the working efficiency and time cycle of the oil roller

2. The customer needs to quickly scan the oil pressure roller, and the scanning data requires high accuracy.

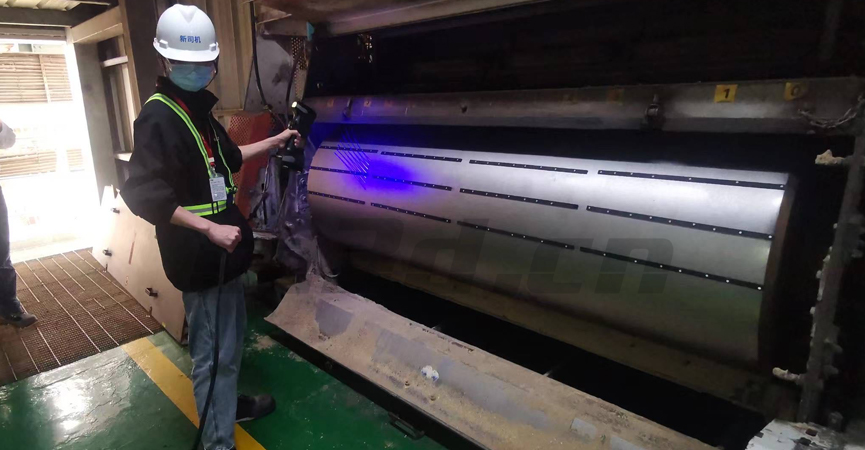

Three-dimensional scanning site map of oil pressure roller

解决方案| Holon solutions

In the inspection of the oil pressure roller, due to its huge and bulky volume, the surface data requires very high accuracy. The traditional inspection method is used to measure, and many small defects cannot be effectively measured, which is easy to produce secondary errors, affecting the subsequent use of the equipment. In order to abandon the traditional detection methods, the enterprise uses a hand-held 3D scanner to detect the product quality of the oil pressure roller, and develops a fast and efficient detection scheme. Hualang technical engineers put forward a solution: use handheld 3D scanner to collect 3D data on the surface, and obtain 3D detection analysis report, providing an effective solution for efficient production of enterprises.

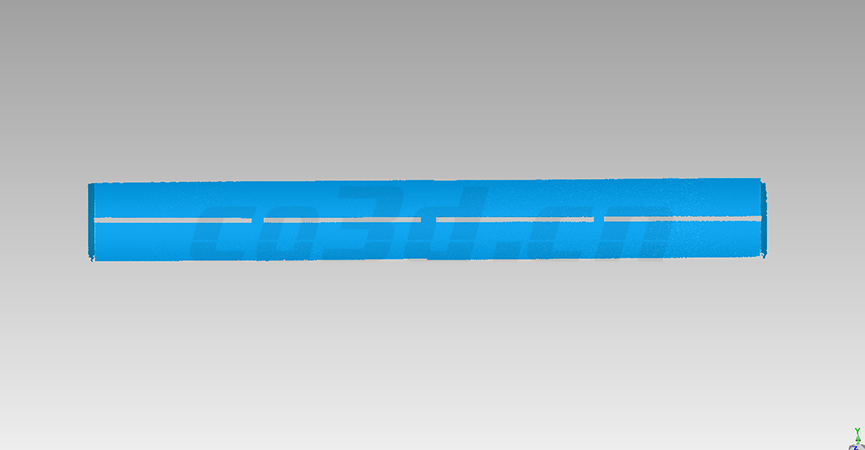

STL data diagram of oil pressure roller

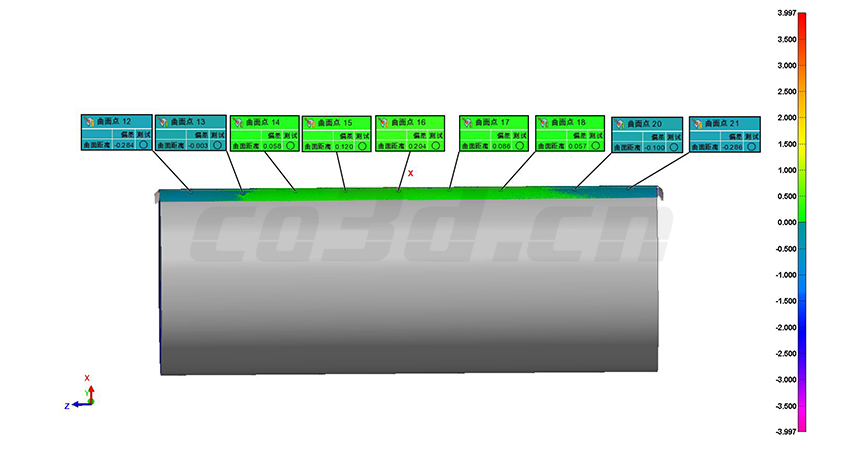

Three-dimensional comparison diagram of oil pressure roller

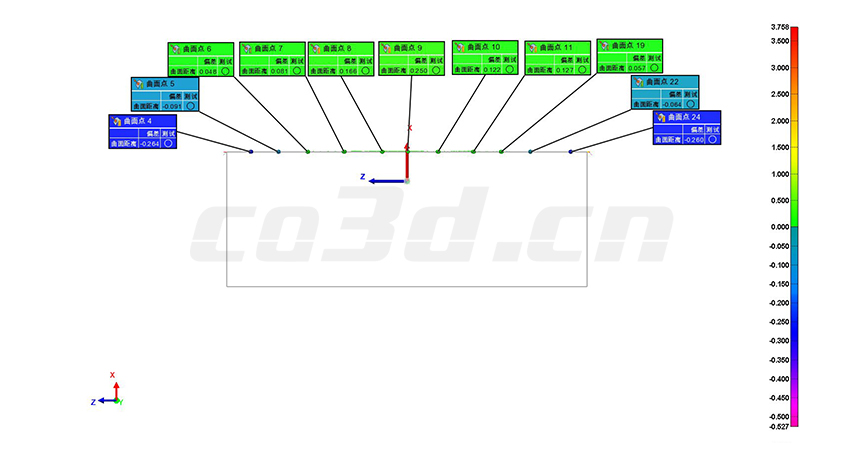

Two-dimensional comparison diagram of oil pressure roller