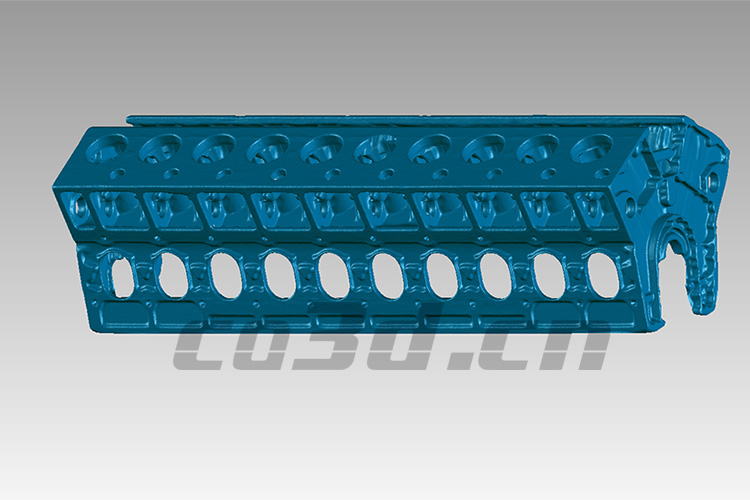

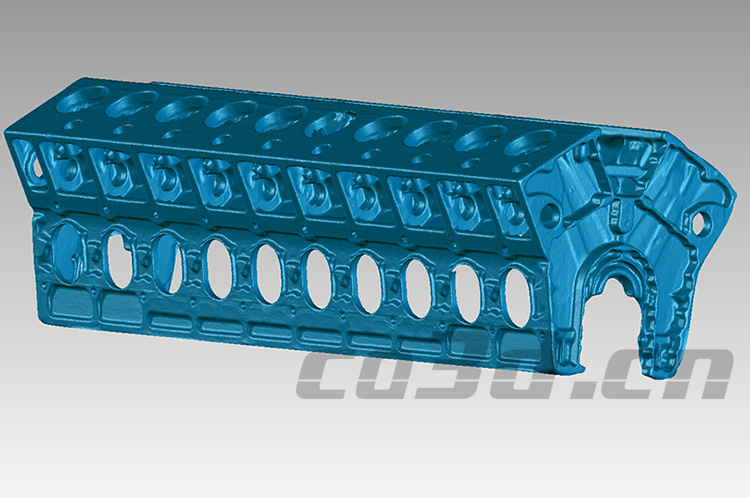

A diesel engine is a type of internal combustion engine that primarily utilizes the combustion of diesel fuel to generate energy. It has the characteristics of high efficiency, high power, and durability, and plays an important role in industries, transportation, and agriculture. With the advancement of technology, the performance of diesel engines will further improve. A well-known manufacturer uses a 3D scanner to perform 3D scanning and reverse modeling.

Practical problems

The internal structure of the workpiece is complex and variable, with a large volume and a large measurement workload. The measurement speed needs to meet customer requirements, and there are many surface holes, which greatly increases the difficulty of collecting detailed data of the parts

Co3d solution

Based on the problems faced, Hualang engineers use a handheld HOLON B71 to quickly switch between corresponding scanning modes for different features. Small features of the parts can also be perfectly captured, enriching detailed data, and achieving a maximum scanning accuracy of 0.01mm. For scanning large parts, a wide range mode is used to maximize the use of cross laser, with a speed of up to 2.02 million times/second. Data is quickly captured and contour data is immediately generated. Importing scanned 3D data into reverse design software allows for reverse modeling. Improve work efficiency and address customer needs.