A well-known washing machine manufacturer needs to conduct a three-dimensional inspection of the washing machine control panel.

Practical problems

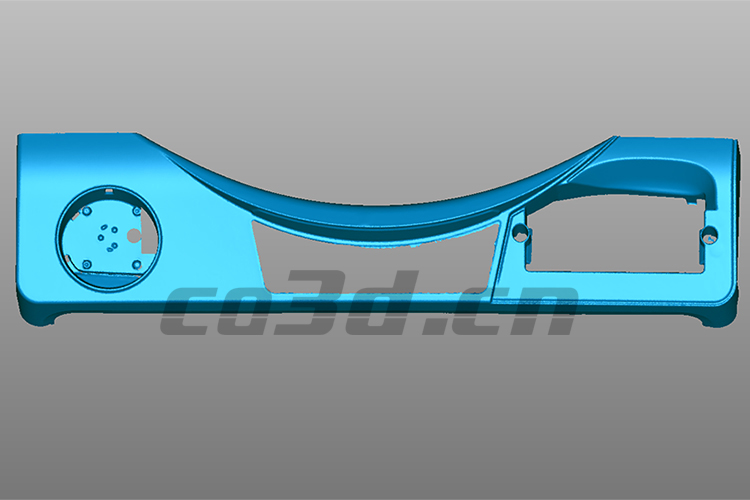

The control panel of the washing machine has multiple operation buttons, and there are many hole positions on the surface of the buttons. Customers need to detect the hole size of the workpiece. Traditional measurement methods cannot fully obtain surface data, and the control panel needs to be matched with internal parts, requiring high accuracy in obtaining three-dimensional data.

Co3d solution

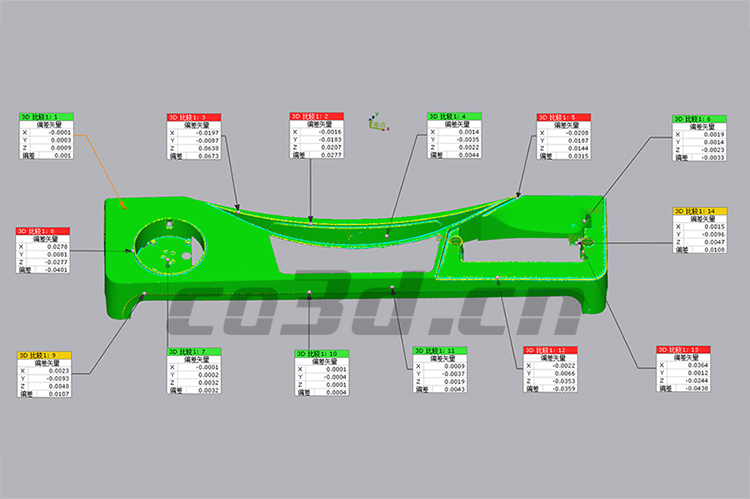

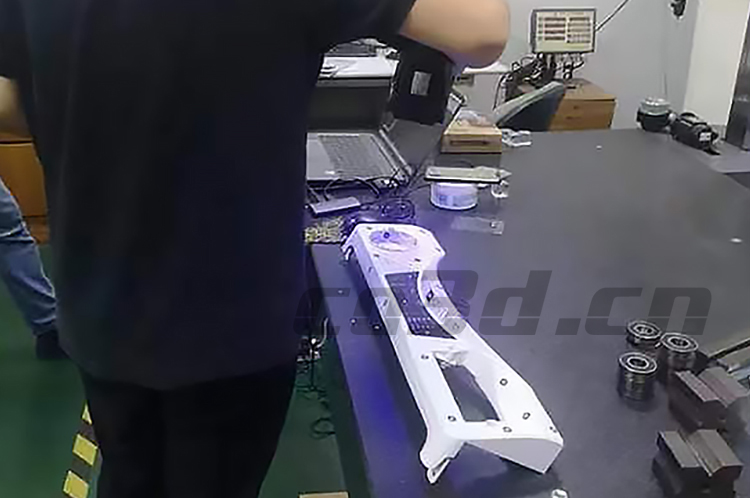

According to customer requirements, Hualang 3D technical engineers use a handheld scanner HOLON B71 to perform 3D data scanning on the control panel, real-time visualization scanning, synchronous data generation, multi line laser data acquisition, with a speed of up to 2.02 million times/second, 1:1 restoration of product data (with an accuracy of 0.01mm), and import the obtained data into 3D software for processing, detection, and analysis. The analysis report is easy to understand, Customers can intuitively understand the problems with the product and provide strong data support for subsequent testing of the product.