Rebar 3D scanning

Steel bars are very practical in major projects. Reinforced concrete has been widely used in the market, according to the different positions of steel bar types, there are many uses, steel bars have buckle bars, negative bars, stress bars, rack reinforcement, distribution bars, etc. Steel bars have also been favored by major projects, such as building construction steel bars are essential, railway track laying, etc.

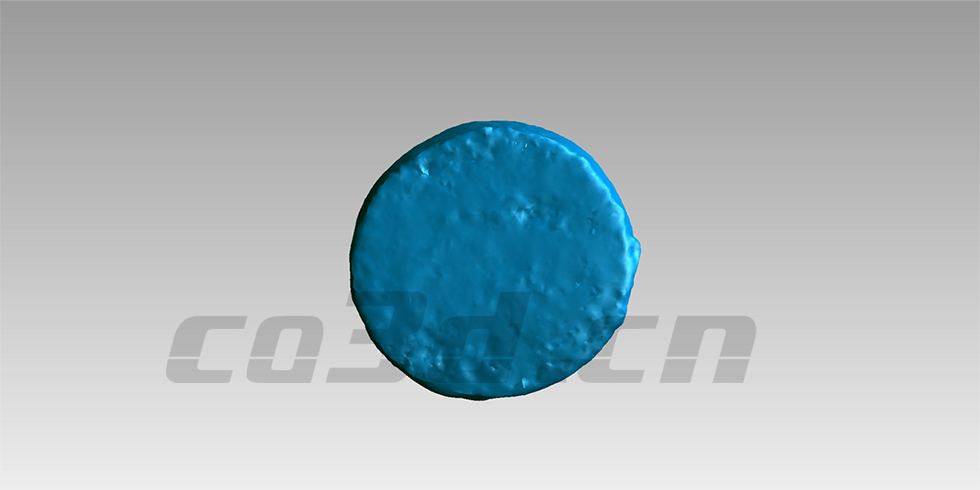

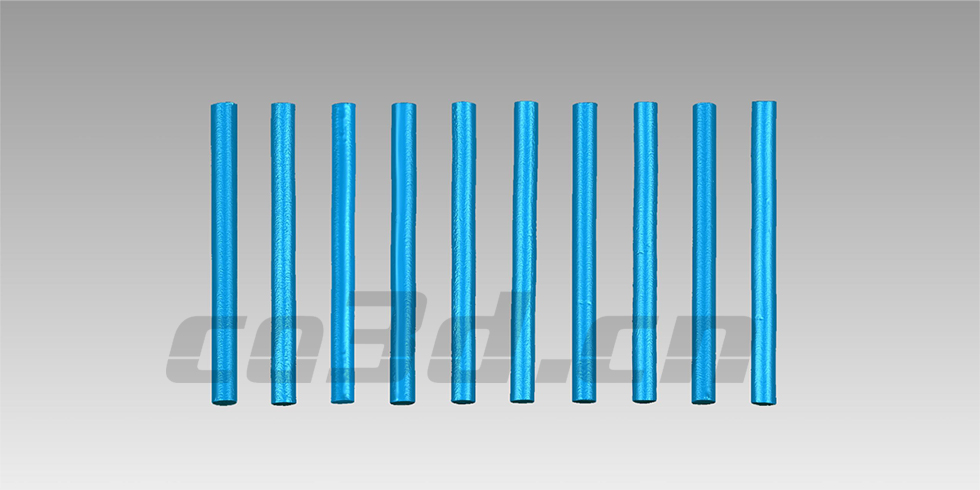

Physical drawing of rebar

Physical drawing of rebar

面临的问题| Practical problems

The customer is required to obtain the surface corrosion of the rebar and detect the degree of corrosion on the surface of the rebar in different time periods. The characteristics of steel corrosion are too small, there are many subtle changes in the surface, traditional methods are difficult to detect, time-consuming and laborious, and the detection accuracy error is too serious. The straight bar is too small, and if it is applied, it will obscure the corrosion characteristics of the surface and affect the test results.

Rebar scan site map

Rebar scan site map

解决方案| Solutions

Hualang 3D technology engineer uses handheld 3D scanner A22, scanning quickly obtains 3D data of different steel experiment conditions, improves work efficiency, handheld is convenient and flexible, light and easy to carry, sensitive and convenient operation process, 22 laser wire harnesses, fast scanning speed, multi-mode switching scanning accuracy, strong stability, a wide range of applications. Use fine mode to sweep out detailed features.

Use the handheld 3D scanner A22 to quickly scan for high-precision rebar surface corrosion. Import three-dimensional software for data optimization, successfully solve customer problems, and achieve the accuracy and effect of customer needs. Accelerate the process for customers to complete experiments.

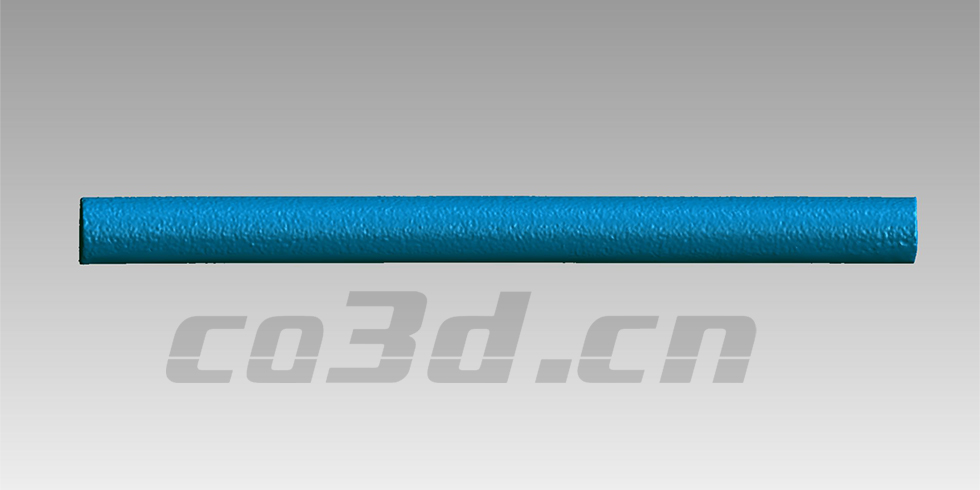

Rebar scan STL data graph

Rebar scan STL data graph

Rebar scan STL data graph