Lens inspection

Most of the lenses are transparent materials with one or more curved surfaces made of optical materials such as glass or resin. Optical resin lenses have strong impact resistance and low price, and are currently widely used lenses. Resin is a chemical substance with a phenolic structure, which is easily deformed during the production process and affects optical properties. The customer wants to detect the deformation of the lens to make adjustments and improve the quality of product sales.

Site scan

Practical problems

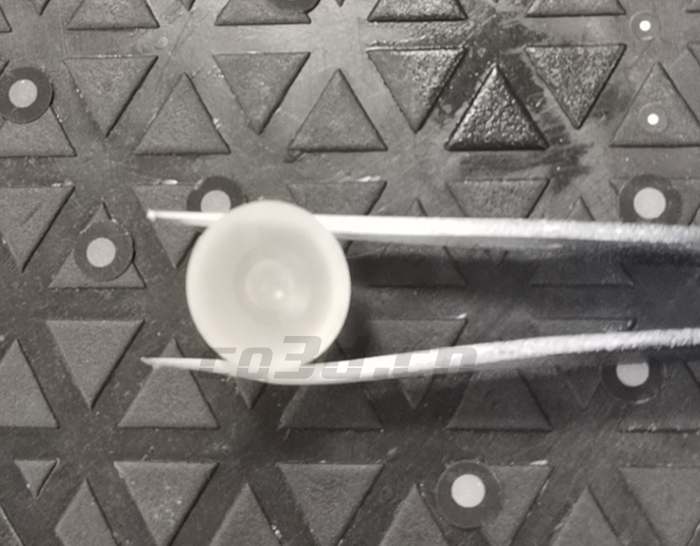

The lens that the customer needs to detect is about a dime, transparent and concave and convex, and requires complete scan data and high accuracy. Using a general three-dimensional scanner, the scanning effect is not up to the requirements, the data acquisition accuracy is not high, and the detection work cannot be completed. Therefore, a new three-dimensional scanning technology is used for scanning.

Site scan

Co3d solution

According to customer needs and workpiece conditions, Hualang technical engineers quickly gave a solution: use HOLON751 handheld 3D scanner.

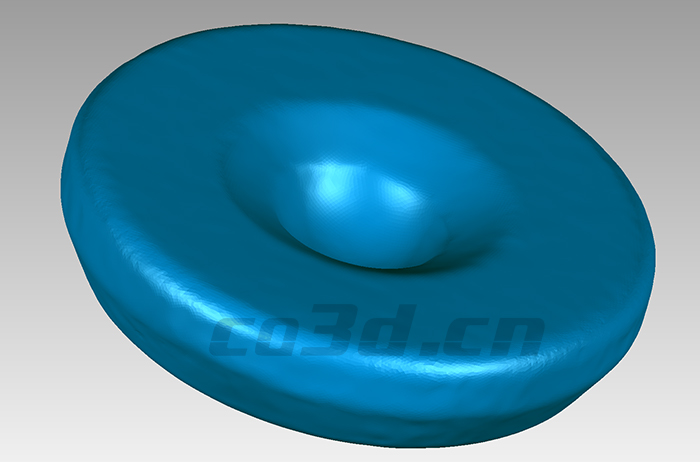

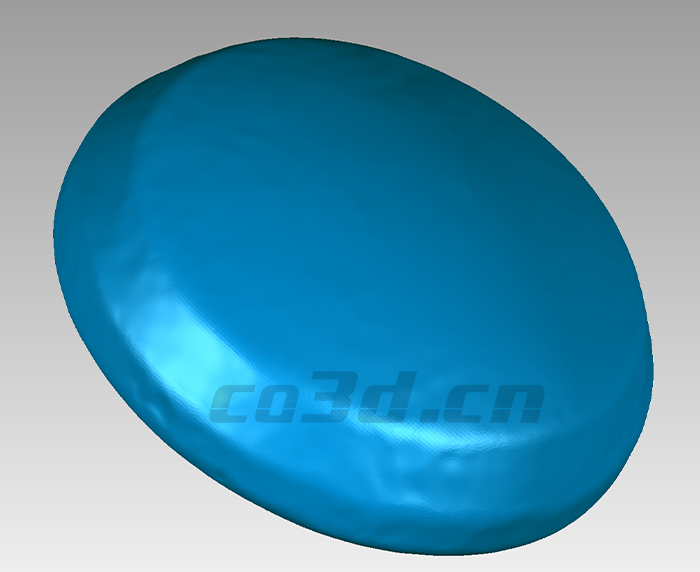

Scan STL data graph

Since the lens is a transparent object, you need to spray a layer of powder on the surface first. Because the lens is small, the HOLON751 fine mode is used for comprehensive and fast scanning to obtain high-precision data. Fine mode is suitable for scanning small objects, with fast speed, high precision and easy scanning. Import the acquired data into the three-dimensional inspection software for comparison and analysis with the original digital model, and generate a concise and clear inspection report to clearly know the problem of the object and make improvements.

Scan STL data graph