3D scanning of gypsum carving

Compared with the scale and types of traditional industries, sculpture has far broken through the original industrial model dominated by stone carving, and the carving industry has gradually transformed from traditional to modern carving industry. Most manufacturers have adopted efficient and convenient methods to measure the 3D data of carving samples in the early stage of carving production, which is different from the traditional measurement scheme, The 3D scanning measurement scheme, with its unique principle of automatic splicing of laser and reflective marker points, has greatly surpassed the traditional measurement method in terms of data quality and measurement efficiency. This new measurement method has gradually been favored by major sculptural art manufacturers.

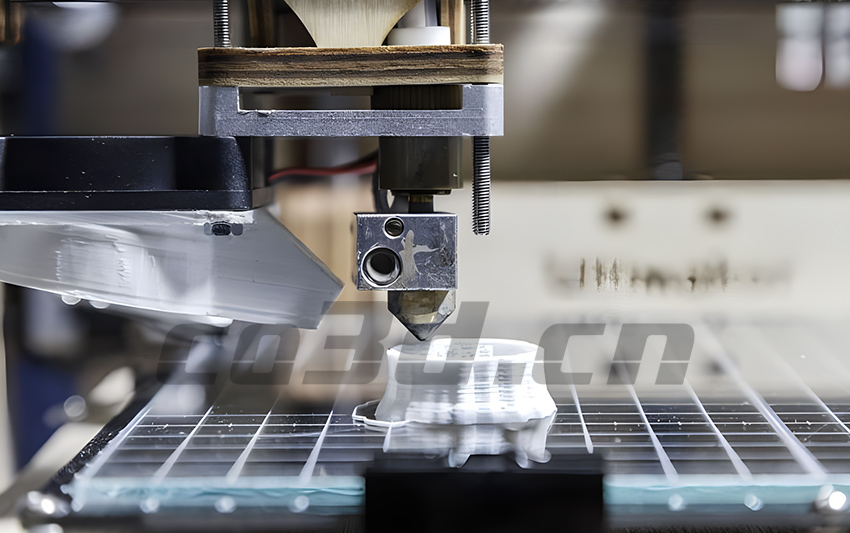

Physical drawing of engraving machine

Manual engraving site map

Practical problem

1. Carved works of art pursue the essence of perfection, and the minute difference in production will lead to the loss of this purpose of their objects. Most of their surface texture is uneven, so the measurement accuracy of carved works is high when collecting data.

2. The variety of carving materials brings more instability to the generation of data during measurement.

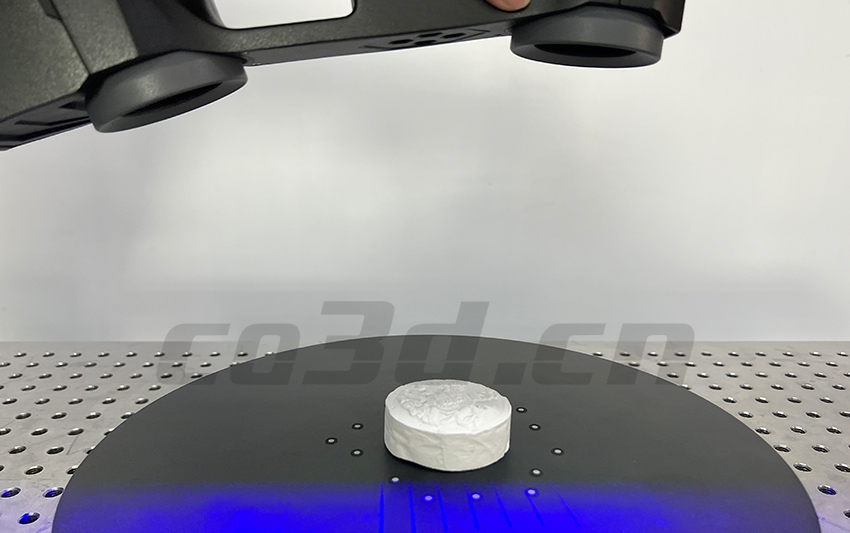

Physical drawing of gypsum carving

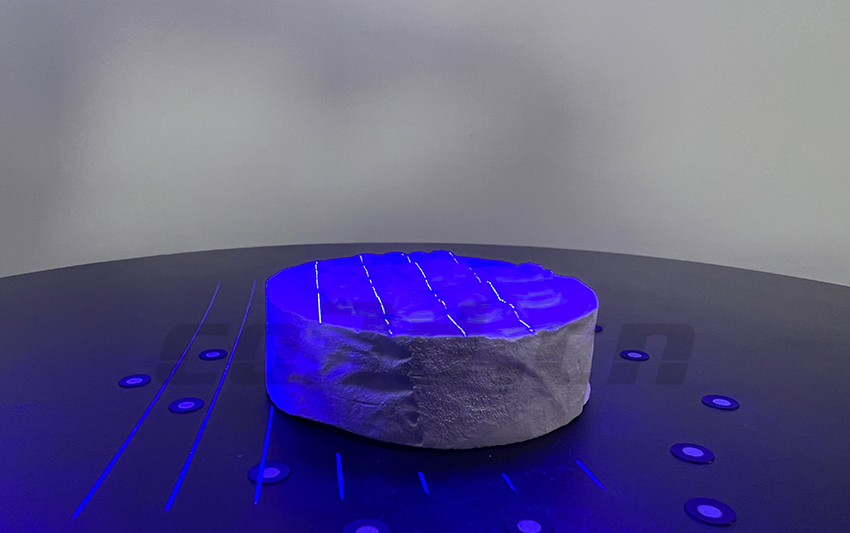

Gypsum carving scanning site

Gypsum carving scanning site

Holon solutions

Several blue lasers cooperate with HOLON's self-developed precision mode to scan the detailed data of the carving piece, which is still handy. With powerful software algorithms, the data can be quickly and automatically spliced, and the 3D data of the carving sample can be restored 1:1. The modern carving industry is gradually pursuing the industrial mode of independent design. The scanned data is highly compatible and can be imported into most mainstream software in the market for secondary reverse design.

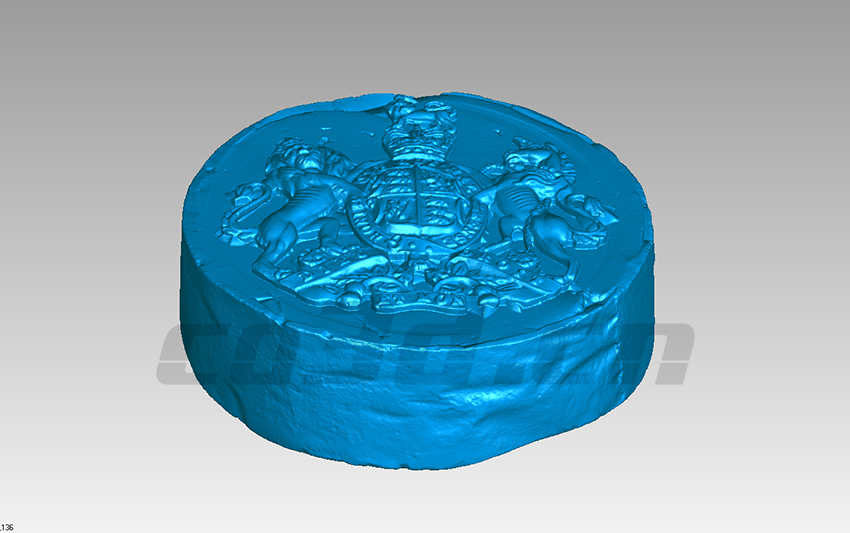

Sculpture STL data diagram

Sculpture STL data diagram