High-end brand bicycle saddle three-dimensional scanning

Bicycle saddles are commonly installed on bicycle seat tubes to provide an indispensable part of sitting support. With the popularity of electric bicycles due to their lightness and environmental protection, the expansion of the electric bicycle market has also promoted the development of the bicycle saddle market to some extent. In the next few years, companies in the bicycle saddlery industry will continue to improve production technology and improve product quality, and the industry competition will become increasingly fierce. A manufacturer should adapt to the current state of development to make corresponding improvements, using 3D scanning technology to detect and analyze.

Bicycle saddle scene scan

Practical problems

The saddle of the bicycle is fan-shaped, with a large curved surface, and the bottom surface is a concave structure with complicated structure. The front part is small or concave and easy to form a dead angle, which makes the scanning work have certain difficulty.

Scanning a smooth surface is possible when trying to use a traditional 3D scanner, but scanning the bottom is time consuming, and the detail scan is not good. The acquired 3D data is not accurate enough to perform accurate scanning and cannot meet customer requirements. . Look for a high-tech scanner.

Co3d solutions

According to the customer's requirements and workpiece characteristics, our engineers use the handheld 3D scanner HOLON760 to quickly scan and obtain 3D data. The device uses 7 sets of crossed laser lines plus an additional laser line to total 15 laser lines, which makes the scanning speed fast. It can be switched into a single laser scanning mode, which is suitable for scanning deep holes and dead angles. The data is scanned with high precision and stability, which greatly improves the working efficiency. The acquired 3D data is imported into the 3D inspection software for comparative analysis. The problem of post design and improvement. The overall scanning process is very fast, and the data is complete and the scanning results in the details are good. The final production analysis report is easy to understand, the user can intuitively understand the defects of the product, and carry out the later improvement, the customer is very satisfied with the scanning effect.

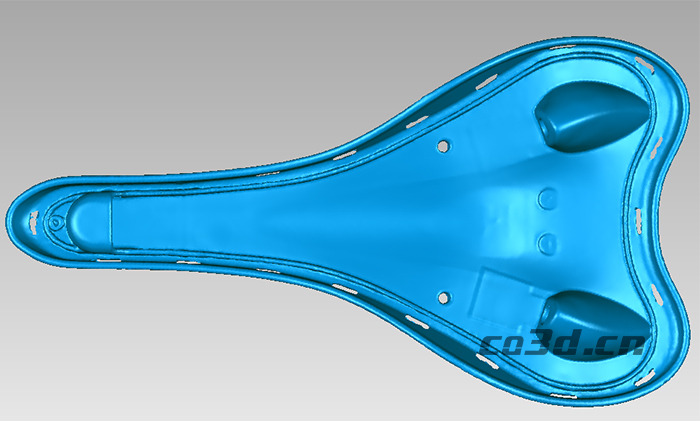

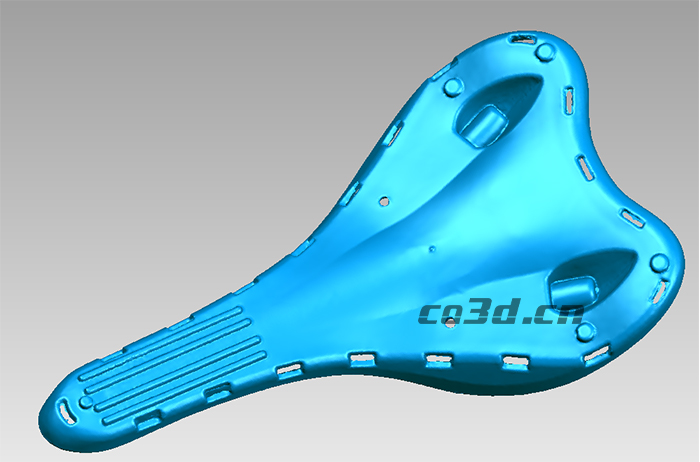

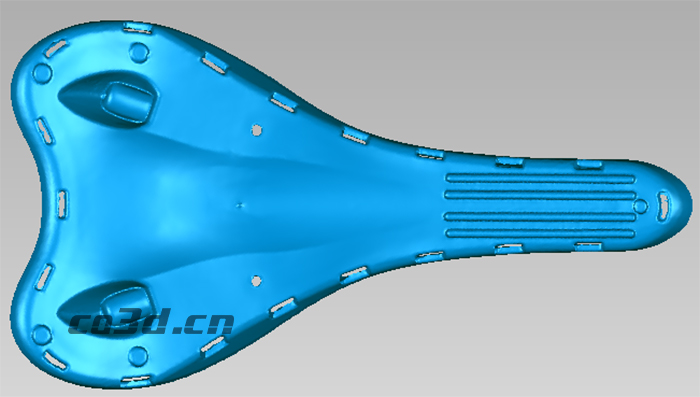

Bicycle saddle STL data chart

Bicycle saddle STL data chart

Bicycle saddle STL data chart