Automobile die, in a narrow sense, is the general name of all stamping parts on the car body. It is also called 'automobile body stamping die'. With the rapid growth of automobile sales, the scale of auto parts is larger than that of the whole vehicle, and 90% of these parts are produced by molds, which is conducive to the development of automobile mold industry. Therefore, the quality requirements of the mold made are high, which need to be compared with the original digital model.

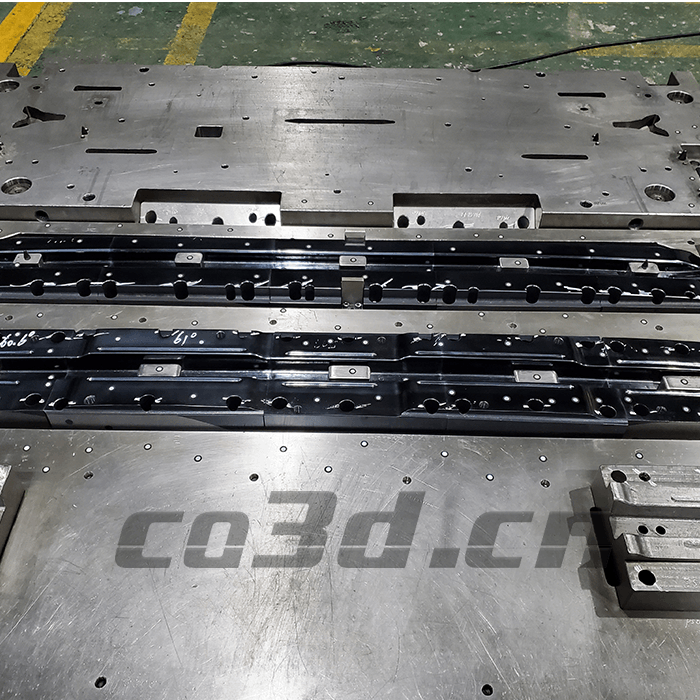

3D scanning on site

Practical problem

The surface structure of the scanned automobile die is more complex, and there are holes in it. Therefore, it is necessary to compare the inspection with the original digital model to check the existing gap. Therefore, the accuracy of the data obtained by scanning is required to be high, and the data can accurately make a comparative analysis report. The traditional measurement method data acquisition accuracy is not high, can not carry out accurate measurement, late can not do comparative detection.

3D scanning on site

Co3d solution

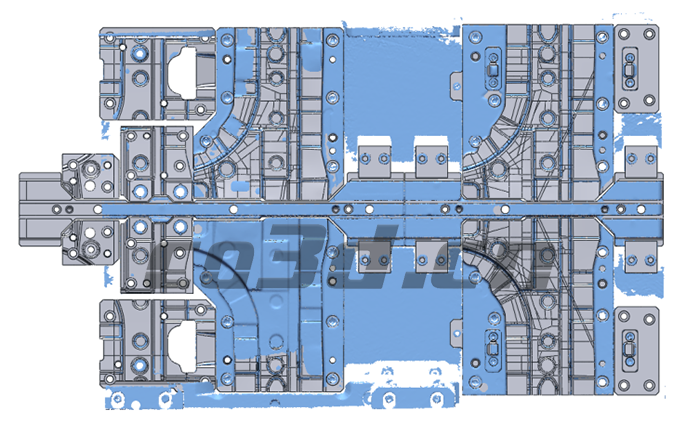

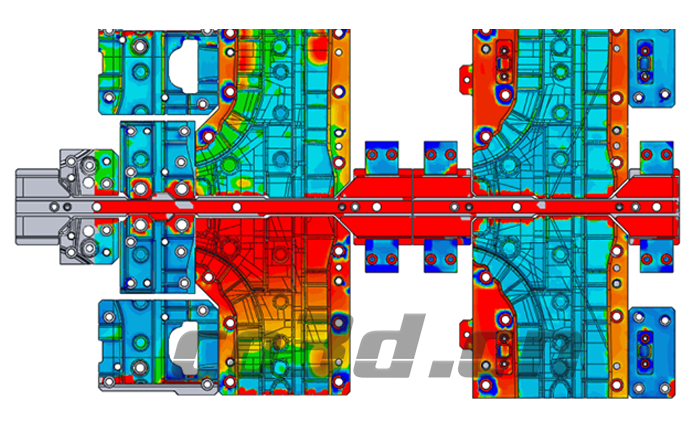

The point cloud data of automobile mould can be quickly obtained by using handheld 3D scanner hollon751, and the scanning can be completed in 20 minutes. This equipment has high scanning accuracy, fast data acquisition speed, and has a single line scanning deep hole mode, which can accurately scan deep holes and obtain automobile mold point cloud data with high density and good restoration of detail features. The acquired data is imported into the testing software and compared with the original digital model to generate a simple and easy to understand error quality report. The results show the difference between the two, which is convenient to improve the product quality and facilitate the later batch production.

3D scanning map

3D scanning map