Aircraft engine soundproof cabin 3D scanning

A large international airline uses our 3D scanner and 3D photogrammetric system to perform 3D measurement on the aircraft engine soundproof cabin to obtain high-precision 3D data detection and analysis products, which is the basis for the later mold opening process and saves cost.

Practical problems

1. Due to the large size of the aircraft engine soundproof cabin, the surface accuracy is high and inconvenient to move. When measuring with a camera-type 3D scanner, the cumulative error will be too large. How to eliminate the impact caused by the error is the biggest problem.

2, the use of traditional measurement methods is not only time-consuming, the data obtained is limited and can not accurately measure the three-dimensional data of the aircraft engine sound insulation cabin surface, can not complete the scanning and data splicing. It is also impossible to complete the quality inspection of the aircraft engine soundproof cabin.

CO3D solutions

In response to the problems faced by the enterprise and the scanning object, the shape technology engineer proposed a solution: using the camera HL-3DS+ and the 3D photogrammetric HL-3DP to quickly and accurately acquire the 3D data of the aircraft engine soundproof cabin combined with the reverse design software. The detection, design and mold opening of the aircraft engine soundproof compartment provide powerful data that solves all the problems faced and meets the needs of customers.

Aircraft engine soundproof cabin scene physical map

Aircraft engine soundproof cabin scanning scene

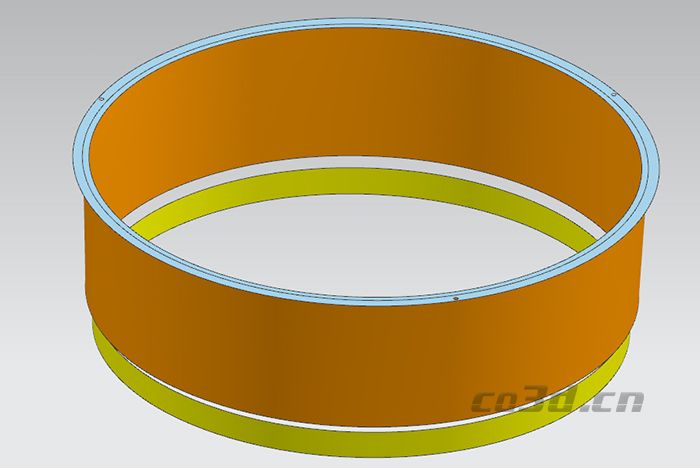

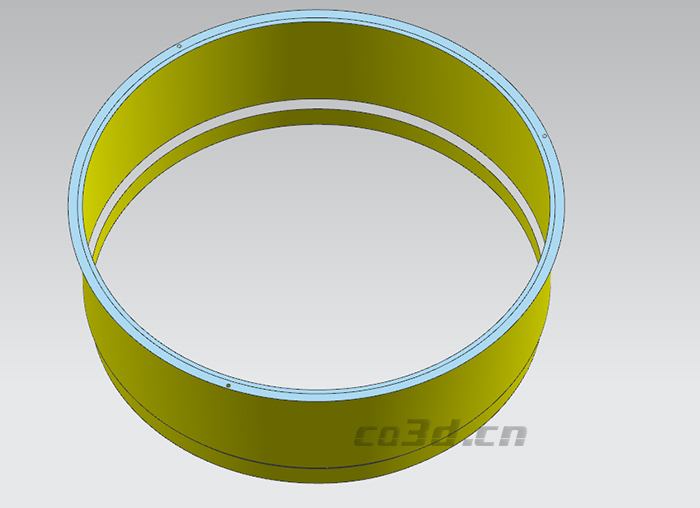

Aircraft engine soundproof cabin 3D data map

Aircraft engine soundproof cabin 3D data map

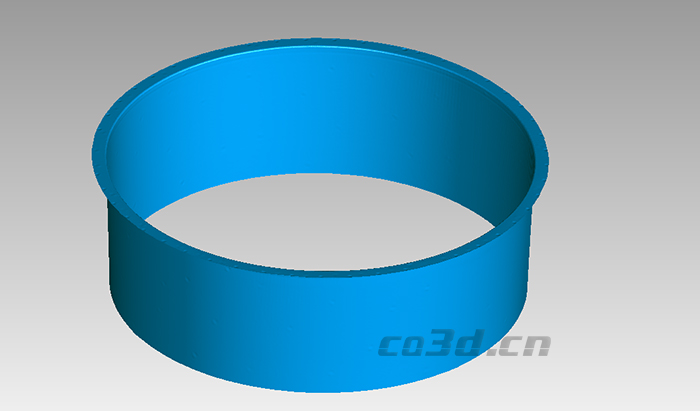

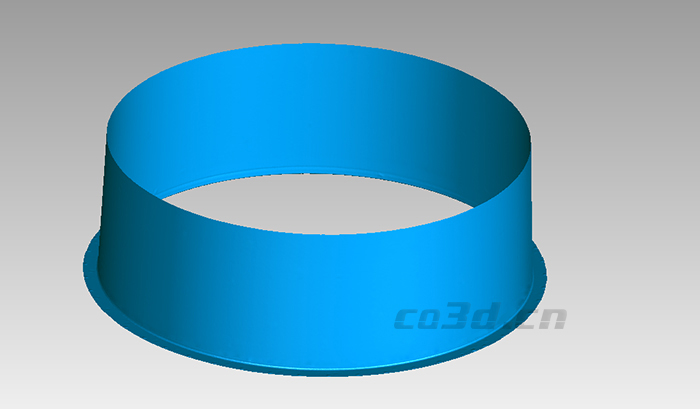

Aircraft engine soundproof cabin STL data map

Aircraft engine soundproof cabin STL data map