Three dimensional scanning of aircraft blade

Aircraft blade is an important component of turbine section in gas turbine engine. The high-speed rotating blades are responsible for drawing high-temperature and high-pressure air into the burner to maintain the operation of the engine. Whether steam turbine engine or gas turbine engine, blade metal fatigue is the main cause of engine failure. Strong vibration or resonance may lead to metal fatigue.

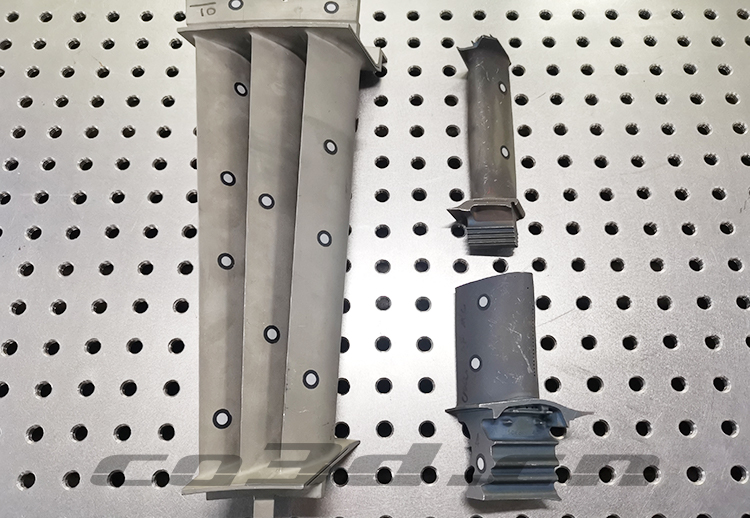

Physical drawing of aircraft blade

Practical problems

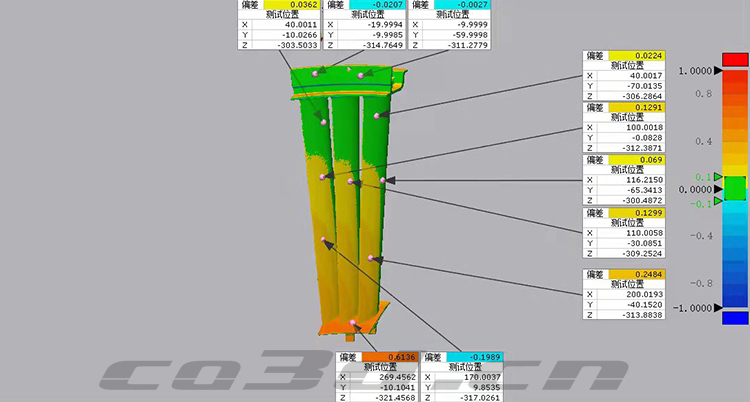

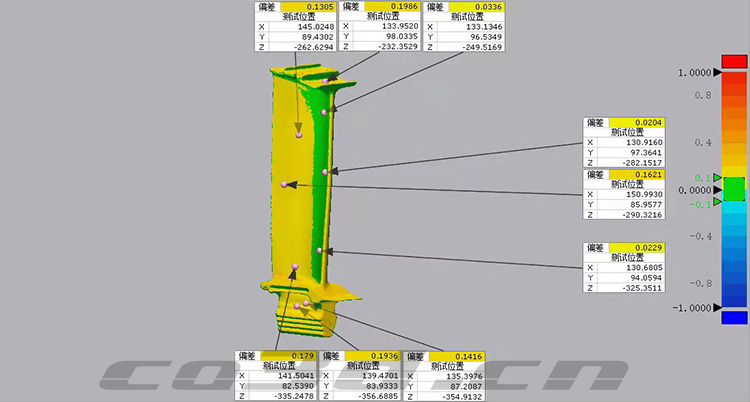

1. Aircraft engine blades generally bear large working stress and high working temperature, and the changes of stress and temperature are frequent and violent. In addition, there are corrosion and wear problems. They have very strict requirements for working conditions, so they require high machining accuracy.

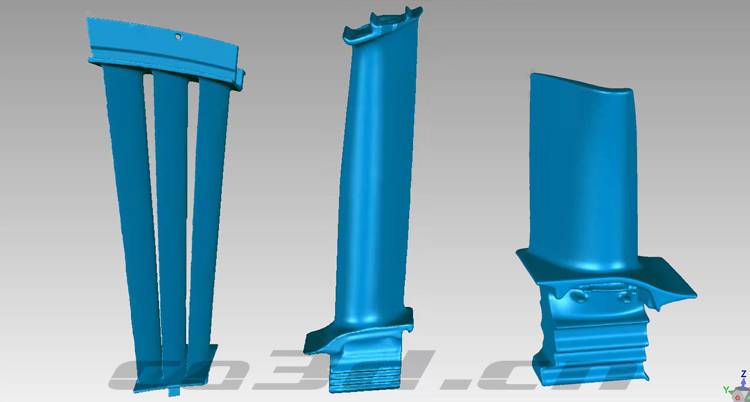

2. At the same time, in order to improve the efficiency of turbine, the surface shape of turbine blade is usually designed as twisted variable cross-section surface, and the shape is complex. Therefore, the accurate geometric modeling of turbine blades has become a necessary prerequisite for aircraft machining.

3. For the airfoil cross-section area, alignment, blade contour, trailing edge radius and blade root shape, three-dimensional measurement needs to be carried out in a nondestructive manner, which is a challenge to the traditional measurement methods.

STL data diagram of aircraft blade

Solutions

Equipment: CO3D handheld 3D scanner Holon B71

HOLON B71 adopts the latest handheld design, light weight and easy to carry; 22 laser lines + 1 deep hole scanning + 7 fine scanning, a total of 30 laser lines. The three scanning modes can scan the variable section surface of the blade flexibly;

Fast scanning speed, high precision and strong stability, dual industrial cameras, automatic splicing technology of marker points and independently developed scanning software; Ultra high scanning accuracy and working efficiency, flexible and convenient operation;

HOLON B71 adopts non-contact scanning, which is ready to use, so as to avoid damage to the blade to the greatest extent.

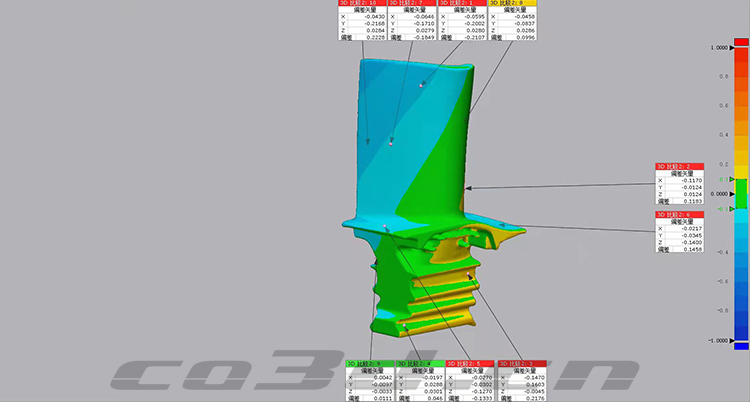

Comparative inspection and analysis diagram of aircraft blades

Comparative inspection and analysis diagram of aircraft blades

Comparative inspection and analysis diagram of aircraft blades