Company Profile

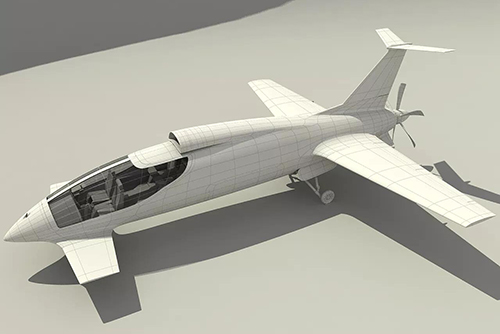

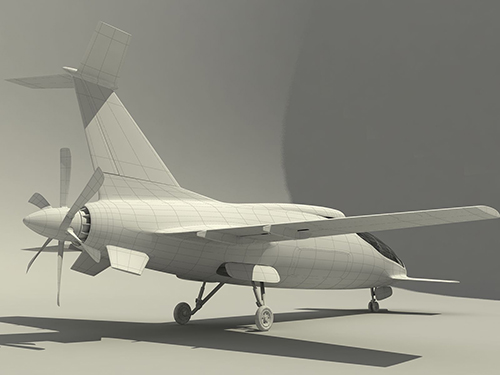

In order to design the aircraft propeller model, a certain AVIC group in China should consider the flight speed and the power transmitted from the engine. The diameter, number of blades, solidity, blade angle, pitch and other factors should be considered in the design process. For a long time, the company hopes to use the 3D scanner to scan the 3D data of the aircraft propeller and reverse design to speed up work efficiency.

Traditional technology

Although our country is a big industrial country and its technology is constantly innovating and improving, it has some problems compared with aircraft manufacturing and entrepreneurial technology. How to solve these problems quickly and effectively is a topic that our aircraft manufacturers have discussed together.

1. The data of the complex parts on the foreign aircraft cannot be obtained, and the advantageous technology that is beneficial to us cannot be extracted from it.

2. The accuracy of the aviation parts is strict. Even if the test is repeated, it is impossible to judge the error as a macro-matched object, and whether it can be perfectly assembled.

3, the most critical engine technology, high-end engines have been in the state of monopoly of developed countries, only the production of high-end independent research and development of the engine, the cost of China's large aircraft can be greatly reduced, and finally gain a foothold in the international market. Under this circumstance, the company decided to introduce Huaguang 3D scanner to solve these problems and introduce the method after Huaguang 3D scanner.

Advantages of introducing Huaguang 3D scanner

Advantage 1: The output interface is extensive, and the obtained data can be programmed in Pro/E, UG and other data, and can be directly modified and innovated on the entity.

Advantage 2: Improve work efficiency, reduce costs, and shorten the development cycle.

Advantage 3: Quickly obtain the comparison of parts error, break through the limitations of traditional detection methods, and shorten the detection time.

Advantage 4: Easily measure multi-curved workpieces and fully capture the data size of the workpiece surface.

Thoughts after the introduction of Huaguang 3D scanner

The customer adopts HL-3DS+ camera-type 3D scanning equipment developed by Huaguang 3D, which mainly carries out three aspects of work, including 3D reverse scanning, 3D modeling and quality evaluation. It has successively supplied large aircraft tail molds for Boeing Company. It plays an important role in the development and manufacture of helicopter propeller molds (military aircraft), large-scale aircraft composite materials, physical prototype parts and complex structural parts. In addition, this technology is widely used in our company's technical transformation projects, especially in the digital transformation process of the old models.