Huaguang 3D 3DH-3M handheld 3D scanner, China's first (first R&D manufacturer), Huaguang handheld 3D laser scanner technology is internationally leading. This product has been widely used in reverse engineering and 3D inspection, using new handheld Design, light weight (950g), easy to carry; ready to use, no need for AC power; product with self-calibration function (module), it uses red line laser, with two industrial cameras, working with angle markers Used in conjunction with scanning software to support photogrammetry and self-calibration techniques. It is especially suitable for on-site 3D scanning, field 3D scanning, large workpiece 3D scanning, and no AC power 3D scanning.

Huaguang 3D 3DH-3M handheld 3D scanner uses 635nm red line laser to scan multiple images of objects before and after deformation through red laser, and calculates the 3D coordinate values of key information points on the surface of the object to obtain object deformation data. Used in: automobile transportation, heavy equipment manufacturing, aerospace, ship engineering, new energy. Scanning range: 0.1~4 meters. Compared with the commonly used dot markers in the industry, the new angular marker points have higher positioning accuracy, mark point synthesis scan and free surface scan. It can quickly and easily perform product shape quality inspection and reverse design of complex workpieces.

Application case: motor car front-end scanning

Faced with problems:China is in a critical period of coordinating urban and rural development. The railway, as an important national infrastructure, a national economic artery and a mass transit vehicle, shoulders major responsibilities in coordinating urban and rural development and speeding up the construction of high-speed railways. In order to improve the competitiveness of the enterprise, a certain motor vehicle manufacturer hopes to carry out detailed analysis on the front end features of the motor car such as hole position, contour and curvature, and then improve the processing to enhance the competitiveness of the enterprise.

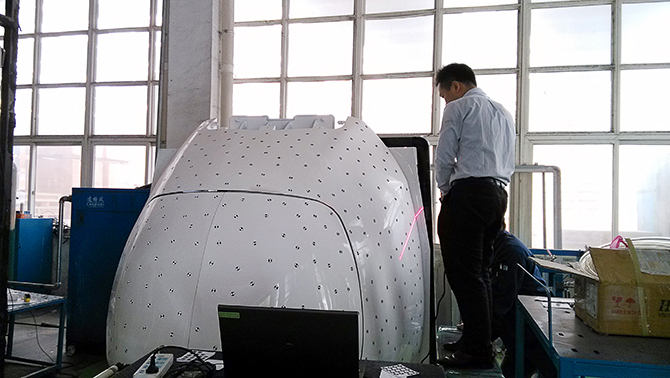

Moving car head on-site scanning physical map

1. The customer scans the front end of the moving car at the factory floor, so there is a high requirement for the portability and stability of the three-dimensional scanning device.

2. The original data collection method of the customer is manual measurement, the precision is not high, and the speed is slow.

3. The quality of the front end of the motor car directly affects the overall performance of the motor car, and the accuracy of the three-dimensional data of the front end of the motor car is high.

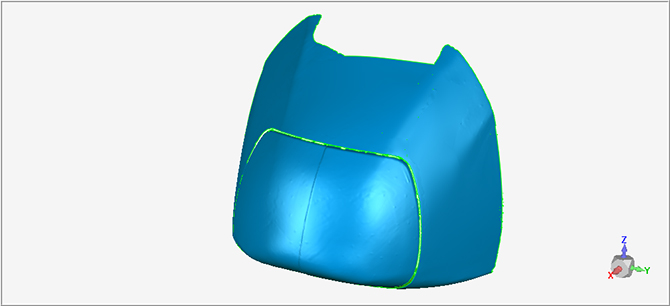

Motor car front STL data chart

solution:In response to the problems faced by customers, Huaguang engineers proposed solutions: HL-3DH-3M (acquiring 3D data of the front end of the car) + reverse design software Geomagic Studio (converting the front-end point cloud data of the car to triangular mesh surface data) + Pro/E, UG and other mainstream design software for post-processing, speed up the secondary design of the front end of the steam car. HL-3DH-3M is a hand-held 3D scanner with laser light source. It is easy to operate and easy to carry. The power interface is connected to 12V/1A DC power supply, which is very suitable for small scanning environment or carrying business trips.

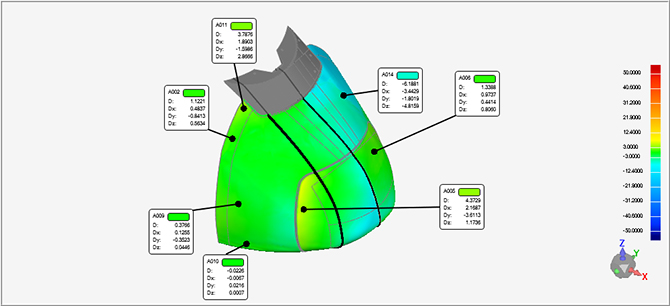

Motor car front comparison analysis data chart