Digital revolutions such as augmented reality (AR)/virtual reality (VR), autonomous driving, ultra-high frame rate shooting, and automated robots have opened up infinite possibilities for people's lives. One of the key devices that enable all of this is the 'image sensor', which is a device that converts light signals into electrical signals.

The SPAD image sensor is a special image sensor. The term 'image sensor' immediately reminds people of CMOS image sensors in digital cameras, but SPAD sensors work differently.

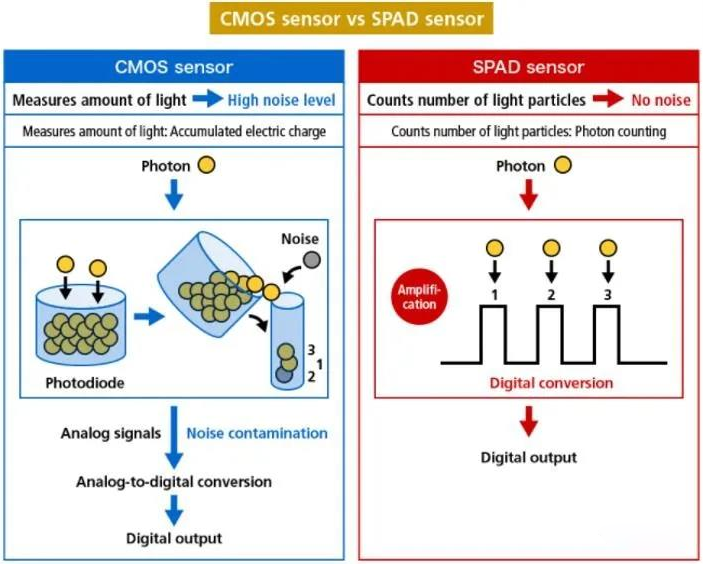

Both SPAD and CMOS image sensors take advantage of the fact that light is composed of light particles. However, each pixel of the CMOS image sensor measures the amount of light that reaches the pixel within a given time, while the SPAD image sensor measures each photon that reaches the pixel. The SPAD image sensor has a diode placed in each pixel. When each diode receives an incident photon, it can convert this photon into a carrier 'avalanche effect', thereby generating a large electrical pulse signal. This ability to generate an avalanche multiplication effect from a single photon can provide higher sensitivity and higher distance measurement accuracy during image capture.

The CMOS image sensor reads electrical signals by measuring the amount of light accumulated by the pixel within a certain time range, which makes it possible for noise to enter the pixel along with photons. The SPAD image sensor digitally counts a single photon, making it difficult for electronic noise to enter, enabling high-precision detection of weak signals and obtaining clearer imaging.

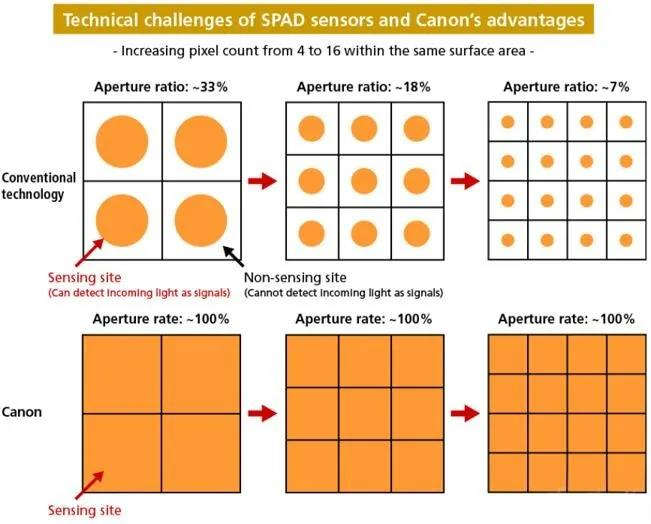

Before this, people have always thought that it is difficult to build a SPAD image sensor with a high pixel count. To this end, Canon has adopted a proprietary structural design mastered through mass production of commercial CMOS image sensors. This design can successfully maintain the aperture ratio at about 100% no matter how small the pixel size becomes, and even if the number of pixels increases, all incoming photons can be captured without any leakage. The result is an unprecedented 1-megapixel SPAD image sensor.

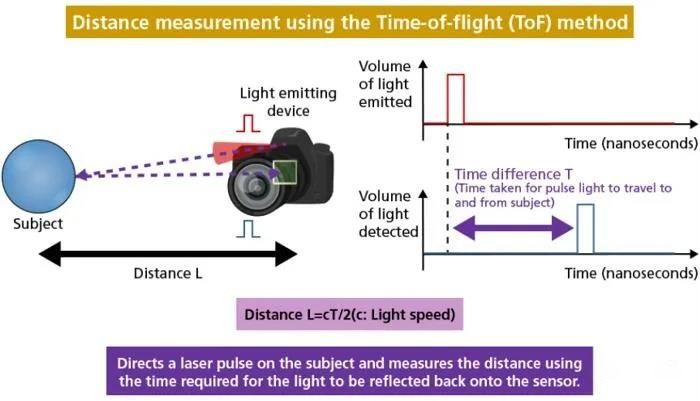

Canon developed this 1-megapixel SPAD image sensor with a time resolution of up to 100 picoseconds, which can achieve extremely fast information processing, making it possible to capture ultra-fast moving objects. This sensor can also use its 'high-speed response' feature for high-precision distance measurement, including 3D measurement. This SPAD image sensor developed by Canon can detect the return light in nanoseconds or less, thereby realizing ToF measurement that cannot be achieved with traditional light sensors. Canon has also equipped this SPAD image sensor with a global shutter, which can capture videos of fast-moving objects while ensuring that the shape of the object is accurate and distortion-free.

Using the ToF method for distance measurement, Canon's SPAD image sensor achieves ultra-high-speed image acquisition with a high resolution of 1 million pixels. This facilitates more accurate 3D distance measurement, and can even handle complex scenes where multiple objects overlap.

The successful development of Canon's SPAD image sensor means that the resolution of a 3D camera capable of recognizing depth information can reach 1 million pixels. This performance can provide high-performance 'eyes' for intelligent robots and other devices that human society depends on in the future.

Canon's research and development results will empower many unknown services and products beyond imagination in the future. They can be easily integrated into various devices and can measure depth information very accurately even in a completely dark environment. This feature makes it extremely promising in the 3D environment perception applications of autonomous vehicles and AR/VR devices.