The strongest in the field of aeroengines must be military aviation engines. Based on the engines of civil airliners, they pursue greater thrust and maximum thrust during overtime. Therefore, military engines can be regarded as the pinnacle of human technology.

Countries that are capable of R&D, manufacturing, and production of aero-engines generally do not easily export their own technologies. They only export finished engine products, and some even need to be sent back to the country of origin for maintenance.Up to now, aero engines have to rely on manual and skilled assembly.

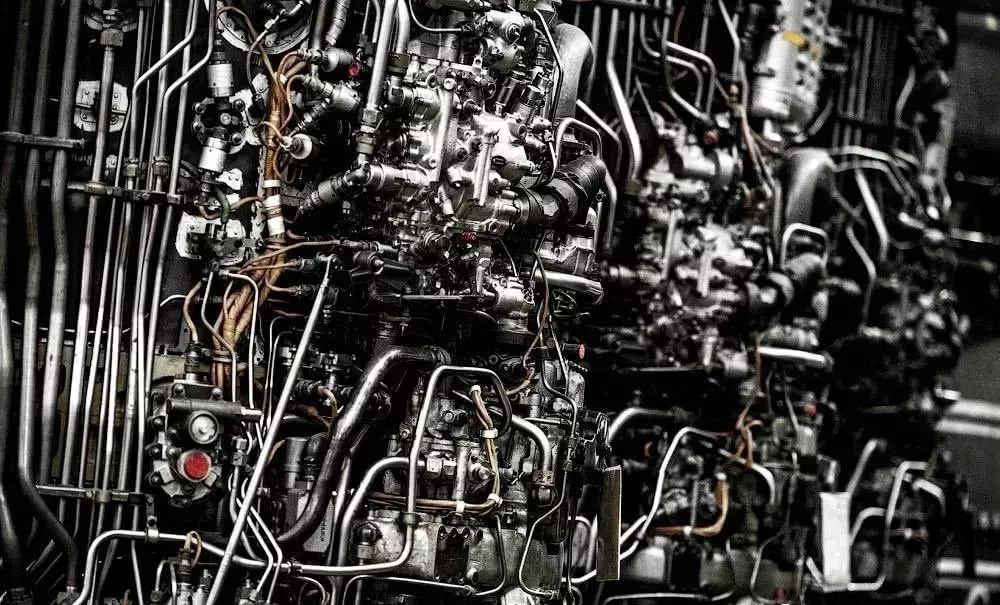

The dense pipelines on the turbofan engine of the NK-25 engine of Figure-22M3. For a long time, this engine and the NK-32 are the most powerful aero engines in the world.

The fuel injection ring of the afterburner of the NK-32 engine.

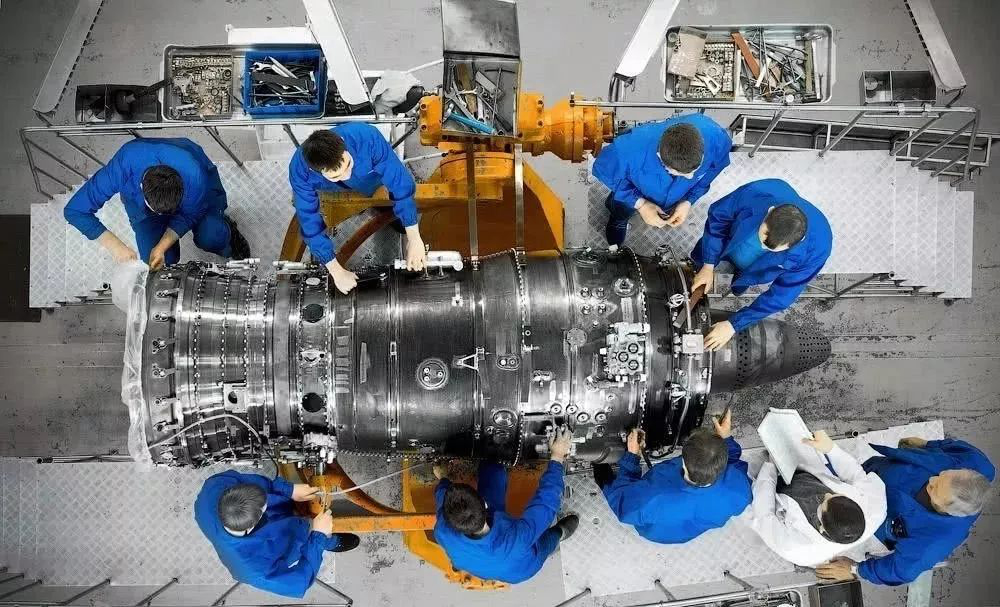

The assembled AL-31FP engine is the power plant of the Su-30SM fighter.

The interface for argon arc welding in the pressurized cabin on the engine casing. Welding titanium alloys in a pure argon environment will not be oxidized, can obtain high-quality welds, and improve the fatigue strength of the welded structure.

The turbine blades of the engine need to be cast and formed, which is sintered ceramic molds using the lost wax method.

Poured single crystal blades are as expensive as the same weight of gold. The technology of casting this kind of blade is very complicated, but the performance of this kind of blade is superior to ordinary blade in all aspects. Each blade is 'grown' with a special nickel-tungsten alloy.

This is a wide-chord hollow blade made for the PD-41 engine, which is the power source for the MS-21 passenger aircraft. The machine in this isolated special area cuts the titanium alloy blade blank, and mechanically polishes and polishes the surface.

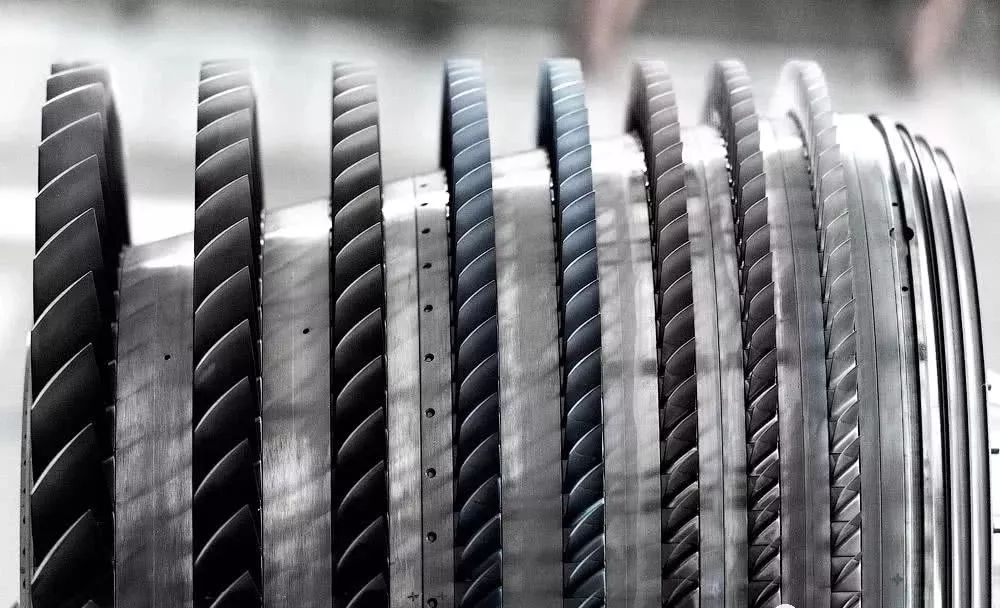

The assembled multi-stage compressor rotor.

Although the jet engine is one of the greatest technological inventions of the 20th century, it still can only be assembled manually by skilled workers.