Large mechanical gear 3D scanning case

With the rapid development of the industrial industry, especially in recent years, the construction of urban and rural areas, as well as roads, railways, power stations, etc., has accelerated the development of mechanical equipment. A Zhejiang enterprise hopes to obtain the three-dimensional data of the super-large gear through the three-dimensional scanner, and compare it with the original digital-analog diagram to obtain the gear detection analysis report to analyze whether the product is qualified.

Practical problems

1. Super large gear is an important part of mechanical equipment, which is related to engineering construction and personal safety, so the customer's precision requirements for the product are very high.

2. The mechanical gear has a large volume and complex shape, many concave and convex structures, irregular shapes and many angular features, which brings great difficulty to the scanning work.

3. The use of traditional measurement methods (such as secondary elements, calipers, three coordinates, etc.) is very cumbersome and time consuming, and it is not easy to accurately and quickly measure and detect the overall structure of the gear.

Large mechanical gear scanning site

CO3D solutions

There are errors in the production process of mechanical gears. Due to the traditional measurement methods, the acquired data is limited and the 3D data of the angular faces of the gears cannot be accurately measured. The 3D technical engineer is used to obtain the gears by using the 3D scanner 3DS+ fast scan. The three-dimensional data is fast, easy to operate and short in time, and the data precision is extremely high, which meets the scanning needs of customers and successfully solves the problems faced by customers.

Large mechanical gear scanning site

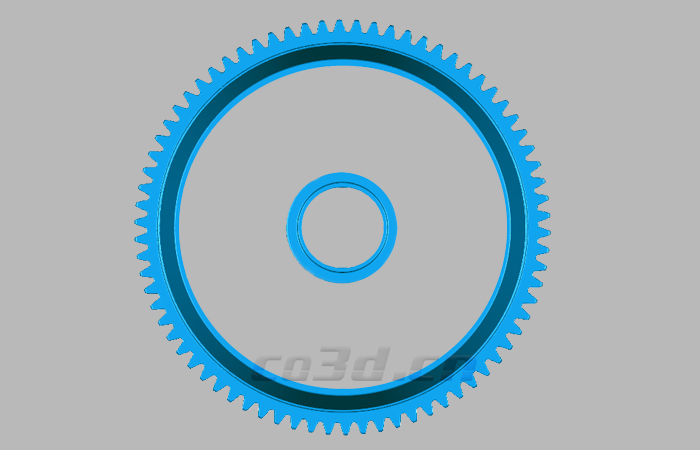

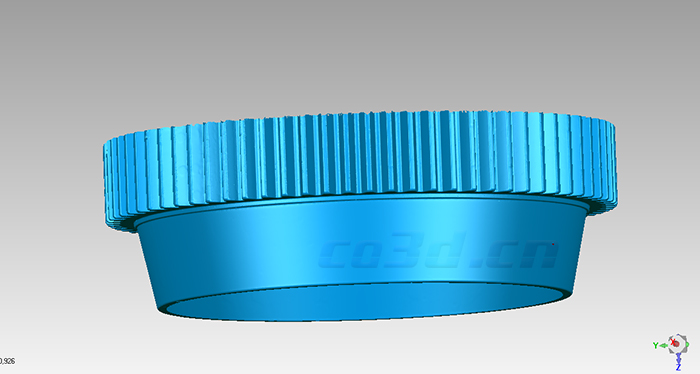

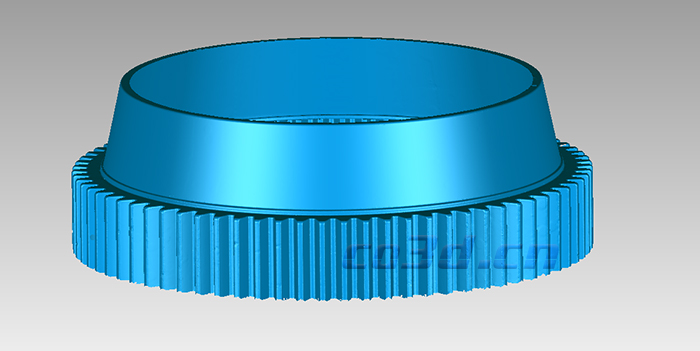

Very large mechanical gear STL data chart

Very large mechanical gear STL data chart

Very large mechanical gear STL data chart