Oil drill bit 3D inspection case

Oil drill bit is an important tool for oil drilling. It is used to drill oil when oil is mined. Its performance will directly affect drilling quality, drilling efficiency and drilling cost.

Practical problems

1. Oil drill bit design is based on practical experience, combined with trial and error method, repeated design and calculation, so the design accuracy is low, the cycle is long, it is difficult to improve the design quality, and only one drill bit can be designed for each calculation, and the efficiency is low.

2. The use of traditional measuring methods (such as gages, fixtures, three coordinates, etc.) is very cumbersome and time consuming, and it is not easy to accurately and quickly measure and detect the overall structure of the petroleum drill bit.

Co3d solutions

Case Description:

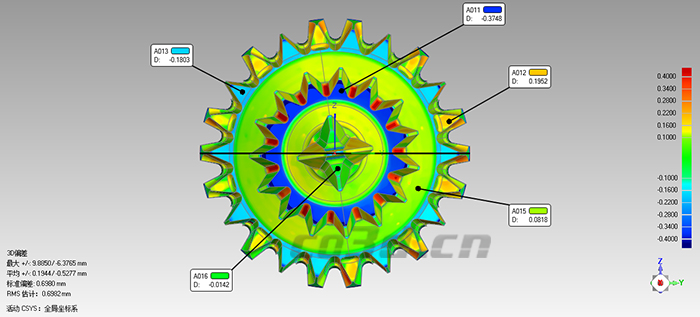

A fluid machinery manufacturing enterprise in Jiangsu has a low precision design, long cycle, and difficulty in improving the design quality. The three-dimensional data of the petroleum drill bit is obtained by using the Hualang 3D scanner to obtain three-dimensional data, which is compared with the original digital model of the petroleum drill bit. Analysis can quickly detect errors and defects in petroleum drill bits.

Scanning equipment:

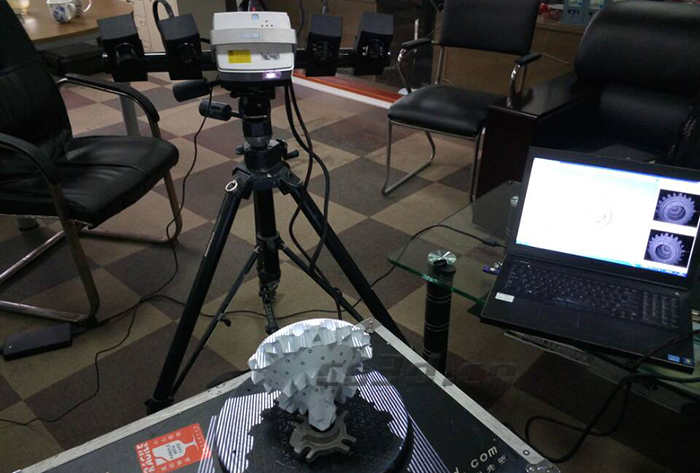

Hualang 3D Scanner HL-3DS+

Features:

● Portable design: The hardware system is small in size, small in footprint, no noise, easy to disassemble and easy to install, and easy to bring to the measurement site.

● Scanning speed is very fast: ≤ 3-5 seconds to get millions of data points, the efficiency is extremely high.

● High precision: single scanning accuracy up to 0.01mm, compatible with photogrammetry system, photography makes scanning faster and higher precision, ±0.0125mm/m.

Oil drill bit scanning scene

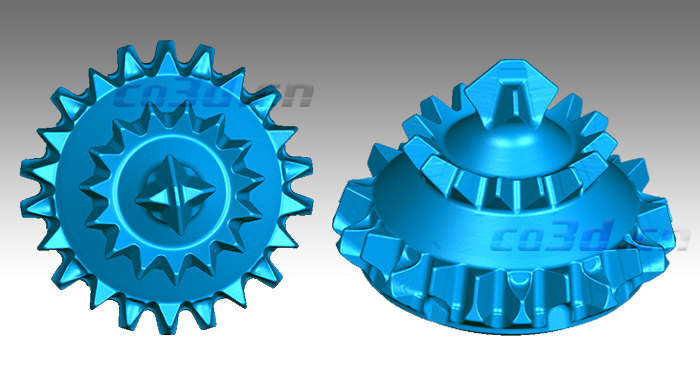

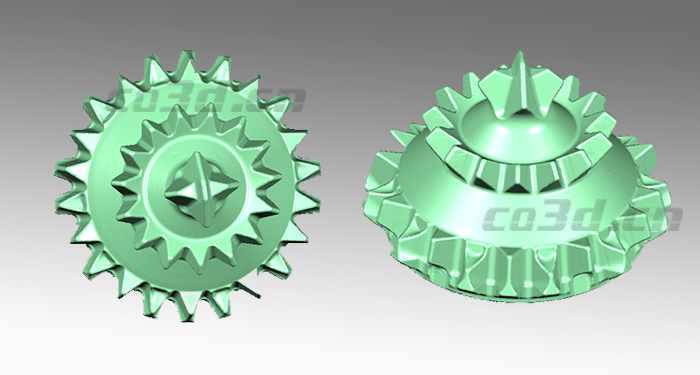

Oil drill bit scans STL data

Oil drill bit scanning point cloud data

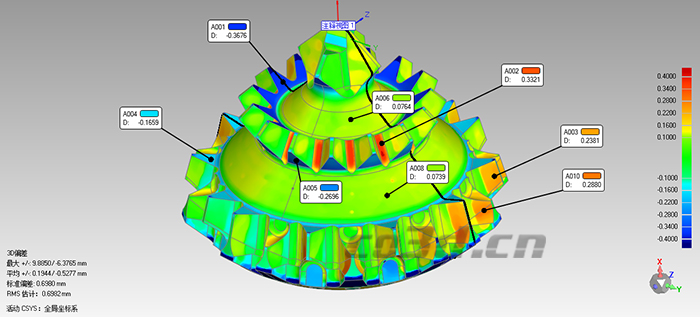

Oil drill bit different position comparison test data

Compare data with raw digital model