Reverse design of mixing equipment blade

With the increasing attention to environmental issues, energy conservation and environmental protection have become the development themes of various countries, and have begun to provide industrial development opportunities for waste treatment. The customer imported a garbage mixing and processing device from abroad, which is convenient for garbage disposal. But there is no drawing, maintenance and repair of the purchased equipment in the later period is a problem. Therefore, customers need to obtain 3D digital models to save data and do reverse design.

Site scan

Practical problems

The stirring processing device mainly scans the stirring blade, which has a large area and requires fast scanning speed and high data accuracy. Due to insufficient data collected using traditional measurement methods, high-precision data cannot be obtained, and subsequent reverse modeling cannot be achieved.

Site scan

Co3d solution

The solution proposed by Hualang engineers: the handheld three-dimensional scanner HOLON751, which has fast scanning speed, high precision and high work efficiency. Use a handheld scanner to scan comprehensively to obtain high-precision data. Import the scanned data into 3D software for processing, and reverse design to obtain a 3D digital model. Customers can save 3D data and reverse modeling for later maintenance and reproduction. Obtain accurate and comprehensive data, reduce the processing difficulty of designers, and speed up work efficiency.

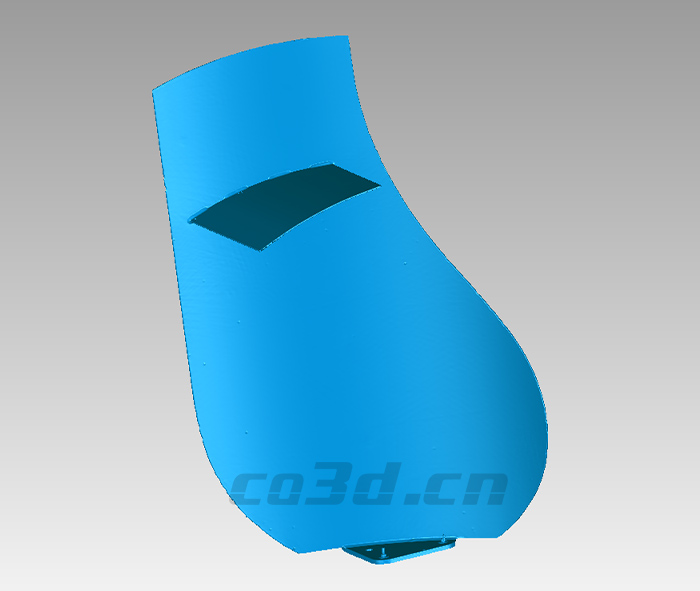

Scan STL data graph

Scan STL data graph