Three-dimensional scanning of large steam turbine cabin

'Our company has developed the original products of the times and market demand with its technical strength, and leads the market with technical solutions that are constantly practiced and innovated.' The customer is a well-known 'wind power group' at home and abroad. It is a place to seek technical solutions and use the new 3D scanning technology to obtain 3D data of the new energy turbine cabin.

Practical problems

3D digitization is applicable to many fields and is an important auxiliary tool for the design and manufacturing departments of the enterprise to improve their development and manufacturing capabilities. In the three-dimensional scanning, due to the huge size of the turbine body of the measured object, scanning by traditional scanning method is not only inefficient, but also the amount of scanned data is small, and the surface information is not complete enough to meet the efficiency and quality of the enterprise. High requirements.

Steam turbine cabin site physical map

he handheld 3D scanner is a popular scanner model in the fields of industrial 3D inspection and reverse design. Its advantages are its flexibility, portability and high precision.

Especially in the face of large objects being measured, traditional camera scanners are slow, and often require dusting and time-consuming labor, while handheld 3D scanners can quickly complete large workpiece scanning with its own flexibility, which is fast and easy to operate. And more efficient.

Recommended equipment: Handheld 3D scanner HOLON760

Co3d solutions

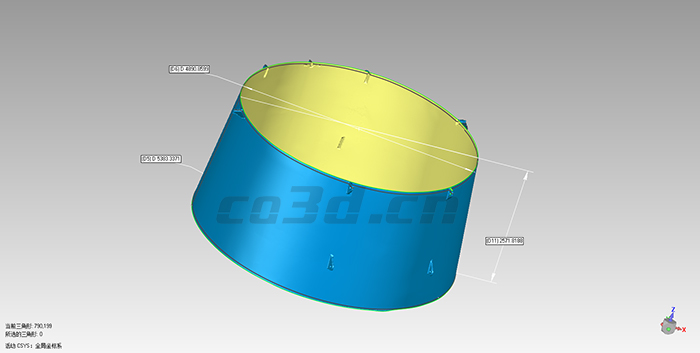

The super-large steam turbine cabin with a circumference of about 20 meters and a height of 8 meters is scanned by HOLON760. It can acquire high-precision three-dimensional data in a short time (about 3h). The method can be completed in about 3 days, and the manual measurement error rate is extremely high and time-consuming and laborious, which is not conducive to the development of the later products and the overall production efficiency of the product. The customer said: This flexible operation method, the speed of data acquisition in such a short period of time, is not possible with the traditional manual methods previously used.

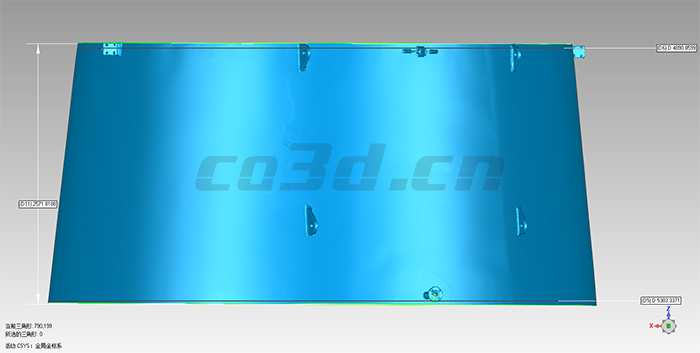

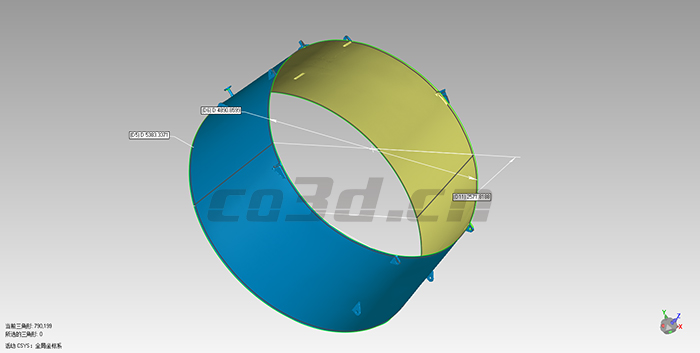

Turbine cabin STL data map

Turbine cabin STL data map

Turbine cabin STL data map

Turbine cabin STL data map

Extended application

1. The sample to be tested can be large or small.

Based on the portability and flexibility of the handheld laser 3D scanner HOLON760, this device has a wide range of operability.

2. Diversified application fields

With HOLON760, everything from product concept design, reverse engineering, to rapid prototyping design and manufacturing, component inspection and repair, and 3D digital archiving can be met. Both efficient and professional, this is the final evaluation of the customer's handheld 3D scanner HOLON760.