Industrial valve inspection

Industrial valves are an important accessory for controlling the flow of media on industrial pipelines. They can be used to control the flow of various fluids, maintain a certain pressure at a regulated rate, and block steam drainage. However, if the connection with each part is not strong, it may cause leakage or be unusable. Need to carry out inspection and maintenance to avoid problems such as defects, leaking sealing surfaces and inconvenient use.

Valve mold scanning site map

Practical problems

The overall structure of the workpiece is complicated, the hole position is large, the volume is small, and the inner wall is scanned, and the bumps are irregular, and the details are scanned a lot, which has certain difficulty.Using some conventional scanners, although the workpiece is small in size, it can be scanned as a whole, but the small parts and the holes are not flat, and the unclearness of the capture is not in place, and the desired effect is not obtained.

Valve mold scanning site map

Co3d solutions

According to various aspects, we decided to use the HOLON760 handheld 3D scanner. The scanner quickly scans and acquires 3D data. It uses 7 sets of crossed laser lines plus an additional laser line for a total of 15 laser lines. In addition, it can be switched to a single laser scanning mode according to requirements, suitable for scanning deep holes and dead angles. Moreover, the system comes with a photogrammetry function, which has high precision, flexible operation and super high work efficiency. Scanning from different angles to obtain data and original data for comparison and detection, the data is complete, the detailed processing effect is very good, and the customer is very satisfied. The analysis report is easy to understand, clear and intuitive to understand the problem.

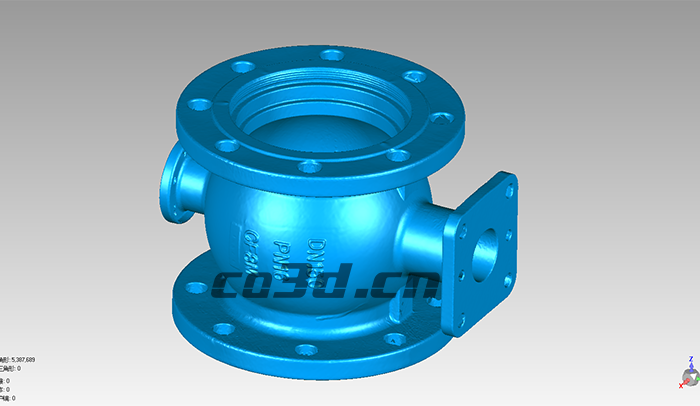

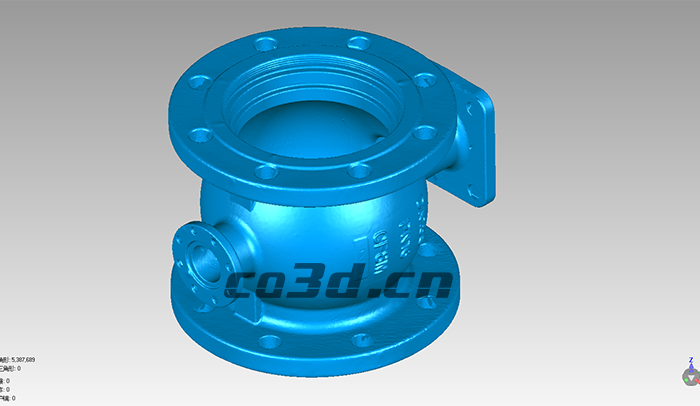

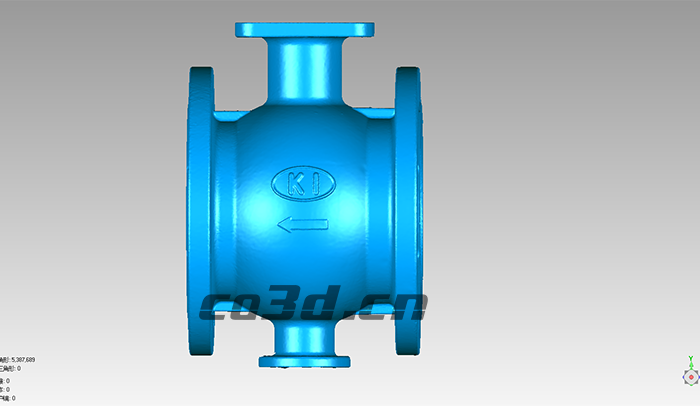

Valve mold STL data chart

Valve mold STL data chart

Valve mold STL data chart