Mold is a tool used to make shaped articles, which is composed of various parts. It mainly realizes the processing of the shape of articles by changing the physical state of the formed materials. Under the action of external force, the blank becomes a tool with specific shape and size. The mould is a precision tool with complex shape, which can bear the expanding force of the blank. It has high requirements for all aspects, so it needs to carry out three-dimensional scanning for testing.

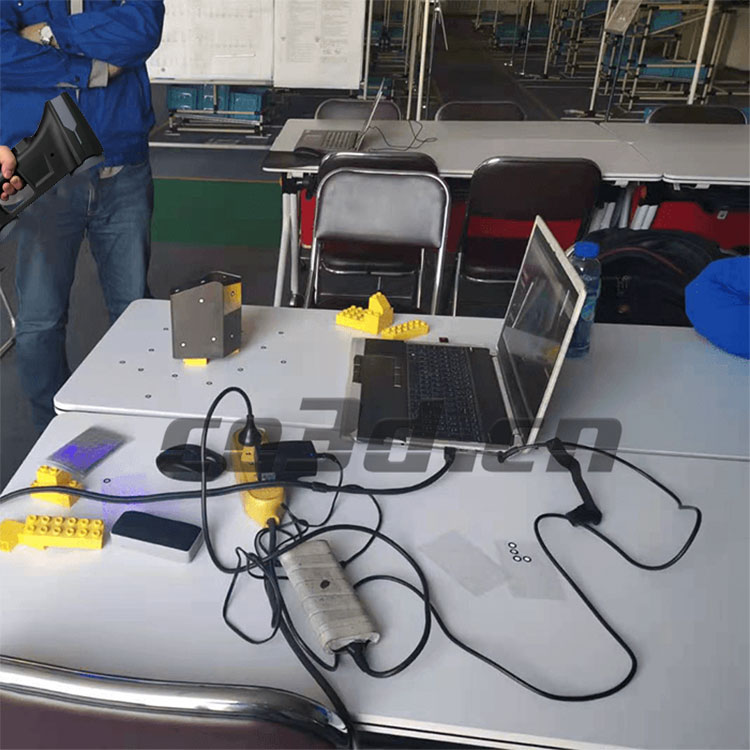

Site scan

Practical problem

The scanning object is black with irregular surface structure and a concave area. Customers need to do mold testing, so the scanning data requirements are high, scanner accuracy is high, can accurately complete the detection work. Using the general three-dimensional scanner, there will be limitations for scanning black objects, which need powder spraying. It is not easy to scan irregular surfaces, which easily leads to low data accuracy.

Site scan

Co3d solution

After understanding the scanning objects and customer needs, our engineers use the hand-held 3D scanner holon751 to scan the scanned mold and obtain high-precision data. The scanning accuracy is 0.02mm, and the scanning speed of multiple laser lines is fast.

Scan data map

The acquired data is imported into 3D detection software for processing, detection and analysis, and simple and easy to understand error detection report is generated, so that the existing problems can be understood and corresponding improvements can be made, and the problems of quality detection and quality control can be solved.

Scan data map

Scan data map