Reverse design of pure copper ornaments

Copper handicraft ornaments may seem very simple, but in fact, the production process of modern copper handicraft ornaments is not just a simple process of assembly and stacking, but requires professional casting technology and precision craftsmanship.

Behind a series of complex processes of pure copper handicraft ornaments, it has brought some difficulties to the early model development and finished product transformation. The traditional development and reverse process is complex and takes a long time. In order to pursue a simple and convenient reverse process, manufacturers decided to use Hualang handheld 3D scanner to conduct 3D measurement of pure copper ornaments.

Scanning physical image of pure copper ornaments

Pracical problems

Reflective material: The surface material of pure copper parts is reflective, which brings great instability to the data during scanning.

Complex texture details: the surface of the decoration has many uneven textures.

Scanning physical image of pure copper ornaments

Solutions

Hand held 3D scanner HOLON B71 Advantages:

High precision scanning:

Blue laser scanning, fearless of black and reflective surface scanning, stable scanning data under high reflective surface, multi line blue light scanning with a maximum accuracy of 0.01mm per frame, high-precision data provides a precise modeling foundation for subsequent reverse engineering.

Convenient reverse:

Scan data and import it into reverse software, high-precision restore handicraft model data, providing comprehensive data support for subsequent decoration renovation.

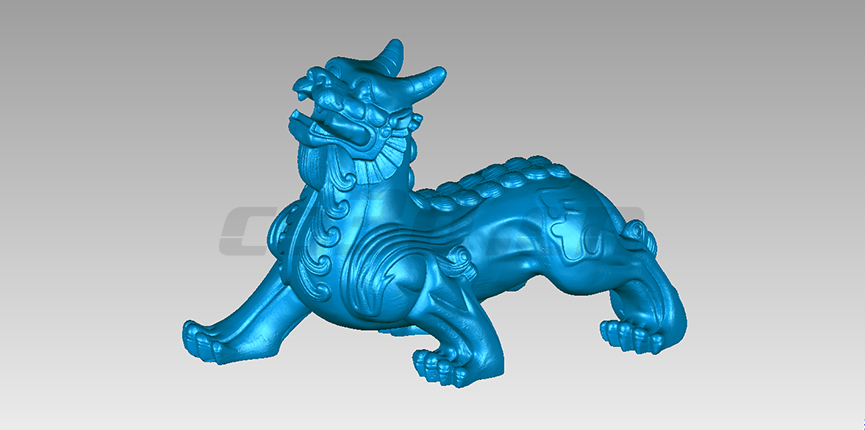

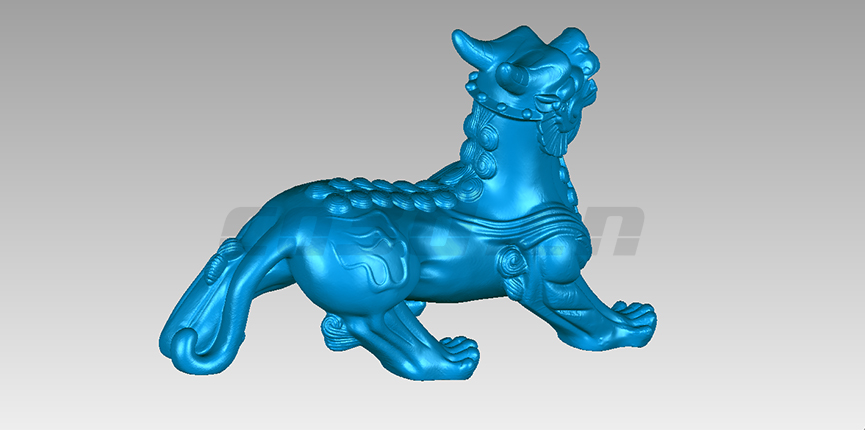

STL data chart of pure copper ornaments

STL data chart of pure copper ornaments