Plastic pipe 3D inspection

The customer is a well-known plastic pipe group in China. Plastic pipes have the advantages of energy saving and material saving, environmental protection, light weight and high strength, corrosion resistance, smooth inner wall and no scaling, easy construction and maintenance, and long service life, so they have a wide range of applications. While the demand is large, quality control is also required, and the pipe diameter size needs to be measured.

Site scan

Facing problems | Practical problems

The customer requires quick scanning to obtain data, and testing based on the data. Moreover, the preliminary preparation work is less, and the operation process is simple and easy to use. The new 3D scanning technology can meet the requirements of quickly and efficiently collecting pipeline data for analysis, which can shorten working time and improve work efficiency.

Site scan

Solution | Co3d solution

The handheld 3D scanner HOLON751 is a new handheld design 3D scanner, which is very easy to carry, easy to operate, fast scanning speed, high data accuracy, and fine scanning, single scanning deep hole mode, suitable for a wide range.

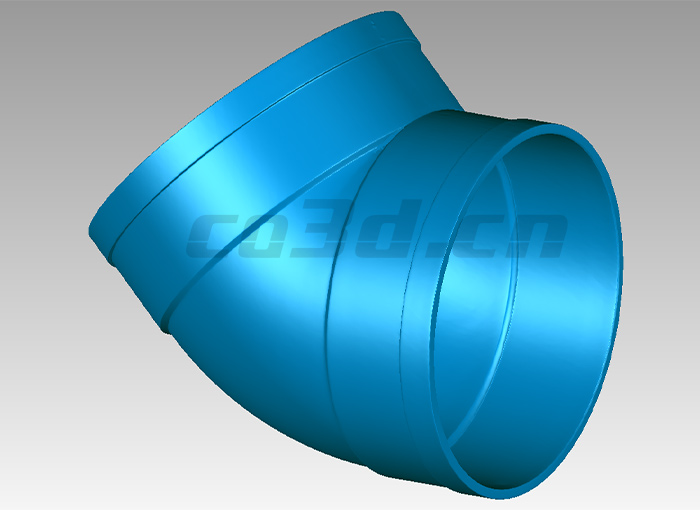

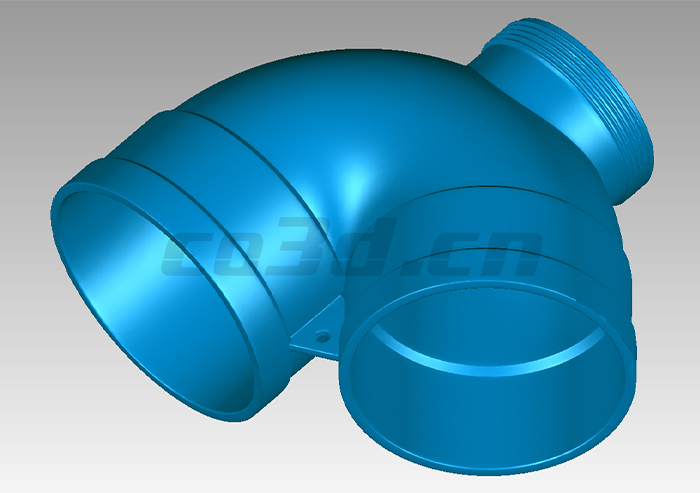

Scan STL data graph

Use HOLON751 handheld 3D scanner for fast scanning to obtain high-precision pipeline data. Import the acquired data into the inspection software to generate a simple and intuitive data analysis report. Therefore, the customer knows the diameter change of the pipe according to the data and makes the corresponding change.

Scan STL data graph